Search

Unveiling the Wonders of Transparent FPC: A Comprehensive Guide

- Apr 27,2025

-

Share

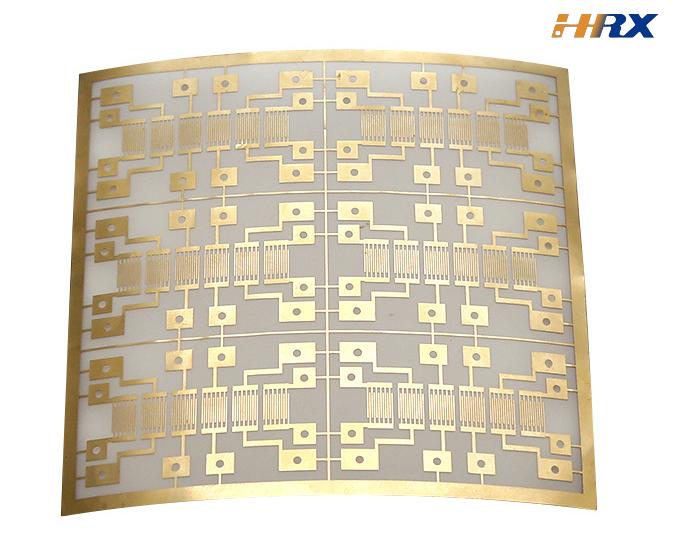

In the rapidly advancing realm of electronics, transparent Flexible Printed Circuits (FPCs) have emerged as a transformative technology, seamlessly merging functionality with aesthetic appeal. As Shenzhen Huaruixin Electronics Co., Ltd., a distinguished industry leader specializing in the design and production of FPC, PCB, and Rigid-Flex Printed Boards, we are eager to impart our profound knowledge and expertise on this cutting-edge subject.

Defining Transparent FPC

Transparent FPCs, a specialized subset of Flexible Printed Circuits, are engineered to combine the advantages of flexibility and transparency. This unique combination enables their seamless integration into a plethora of applications where both visual clarity and compact form factor are of paramount importance. Distinguishing themselves from conventional printed circuits, which are typically opaque and rigid, transparent FPCs offer an exceptional blend of malleability, resilience, and optical transparency. These attributes render them highly suitable for diverse sectors, including wearable technology, aerospace, and consumer electronics, positioning them as a key component in the evolution of modern electronics.

Materials Composition

The performance and characteristics of transparent FPCs are fundamentally shaped by the meticulous selection of their constituent materials. A pivotal material in the construction of transparent FPCs is the high-temperature resistant and high-transmittance PET (Polyethylene Terephthalate) film. Serving as the Flexible Printed Circuit (FPC) substrate, PET film boasts outstanding mechanical properties, chemical resistance, and optical clarity, making it an optimal choice for transparent FPCs. Its lightweight nature, flexibility, and cost-effectiveness further contribute to its widespread adoption across various applications.

Beyond the PET substrate, transparent FPCs incorporate other essential materials. Conductive inks, often formulated with high-conductivity materials such as silver nanoparticles and carbon nanotubes, are utilized to fabricate the electrical traces and interconnections on the FPC. Adhesives play a critical role in bonding the multiple layers of the FPC, ensuring structural integrity. Protective coatings, including conformal coatings, are applied to enhance the FPC's durability, safeguard it against environmental factors like moisture and chemicals, and maintain its optical transparency.

Key Characteristics

Transparent FPCs exhibit a suite of distinctive features that make them highly coveted in numerous industries.

High Transparency: These FPCs offer superior optical clarity, facilitating unobstructed visibility of the underlying components and structures. This characteristic makes them indispensable for applications such as displays, touchscreens, and optical sensors, where clear visual transmission is crucial.

Flexibility: Transparent FPCs are renowned for their exceptional flexibility. They can endure bending, folding, and twisting without compromising the integrity of the electrical traces or connections. This flexibility is particularly valuable in applications where conformability and compact form factors are essential, such as in wearable devices, flexible displays, and medical electronics.

High Conductivity: By incorporating advanced high-conductivity materials, transparent FPCs ensure excellent electrical conductivity and efficient signal transmission. This makes them well-suited for applications demanding high-speed data transfer and signal integrity, including high-definition displays, wireless communication devices, and automotive electronics systems.

Durability: Engineered to withstand harsh environmental conditions, including extreme temperatures, humidity, and exposure to chemicals, transparent FPCs are highly reliable. This durability makes them a preferred choice for aerospace, military, and industrial applications where reliability under challenging circumstances is non-negotiable.

Applications

Transparent FPCs have found extensive use across multiple industries:

Wearable Devices: In the realm of wearable technology, transparent FPCs are employed in smartwatches, fitness trackers, and virtual reality headsets. They enable flexible and transparent connections between components, facilitating ergonomic designs that enhance user comfort while simultaneously improving device functionality and performance.

Aerospace: In aerospace applications, such as aircraft windows, cockpit displays, and satellite communication systems, transparent FPCs provide flexible and transparent connectivity solutions. This not only contributes to lightweight and efficient designs but also enhances the reliability and performance of aerospace electronics.

Consumer Electronics: In consumer electronics, including smartphones, tablets, and laptops, transparent FPCs enable sleek and modern designs by providing flexible connections between components. They also play a role in improving the overall functionality and performance of these devices.

Design and Production Experience

As a leading entity in the FPC, PCB, and Rigid-Flex Printed Board manufacturing domain, Shenzhen Huaruixin Electronics Co., Ltd. has amassed extensive experience in the design and production of transparent FPCs. Our team of seasoned engineers and technicians leverages state-of-the-art design tools and advanced manufacturing techniques to ensure that our transparent FPCs adhere to the highest quality and performance benchmarks.

Material selection is a cornerstone in the design and production of transparent FPCs. We source only the highest quality materials, rigorously selecting high-temperature resistant and high-transmittance PET film, top-grade conductive inks, reliable adhesives, and effective protective coatings. This meticulous material selection process guarantees that our transparent FPCs deliver exceptional optical clarity, flexibility, conductivity, and durability.

The manufacturing process is equally critical. We employ a sophisticated combination of advanced techniques, including photolithography for precise circuit patterning, etching for accurate trace formation, and lamination for secure layer bonding. These processes enable us to achieve the highest level of precision and accuracy, meeting the most exacting requirements of our customers, whether it involves tight tolerances, complex geometries, or high-volume production runs.

Key Considerations

When embarking on the design and production of transparent FPCs, several critical factors must be carefully considered:

Optical Clarity: For applications such as displays and optical sensors, the optical clarity of the transparent FPC is of utmost importance. To achieve and maintain high optical clarity, it is essential to utilize premium materials, implement precise manufacturing processes, and minimize the presence of defects and impurities within the FPC.

Flexibility: In applications where flexibility is a key requirement, such as wearable and flexible display technologies, it is crucial to select materials and manufacturing processes that can withstand repeated mechanical stress, including bending, folding, and twisting, without causing damage to the electrical traces or connections.

Conductivity: For applications demanding high-speed data transfer and signal integrity, optimizing the conductivity of the transparent FPC is essential. This involves using high-conductivity materials, refining the design of electrical traces and connections, and implementing appropriate manufacturing techniques.

Durability: In industries like aerospace and military, where the FPC must endure harsh environmental conditions, ensuring the durability of the transparent FPC is non-negotiable. This requires the use of robust materials and manufacturing processes capable of withstanding extreme temperatures, humidity, and chemical exposure.

Conclusion

Transparent FPCs represent a revolutionary advancement in electronics, offering an unparalleled combination of flexibility, durability, and optical clarity. At Shenzhen Huaruixin Electronics Co., Ltd., we take pride in our position at the vanguard of this technology. Our commitment to excellence is reflected in the high-quality transparent FPCs we produce, which are tailored to meet the most exacting requirements of diverse applications. If you have any inquiries or wish to explore our transparent FPC offerings further, please visit our website at www.hrxfpc.com or contact us via email at sales@hrxfpc.com. We look forward to collaborating with you and contributing to your next innovative project. Don't miss out on the latest in transparent FPC technology – reach out today!

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP