Search

Key Design & Production Considerations of FPC for Foldable Phones: Huaruixin's Quality Assurance & Core Technologies

- Jan 13,2026

-

Share

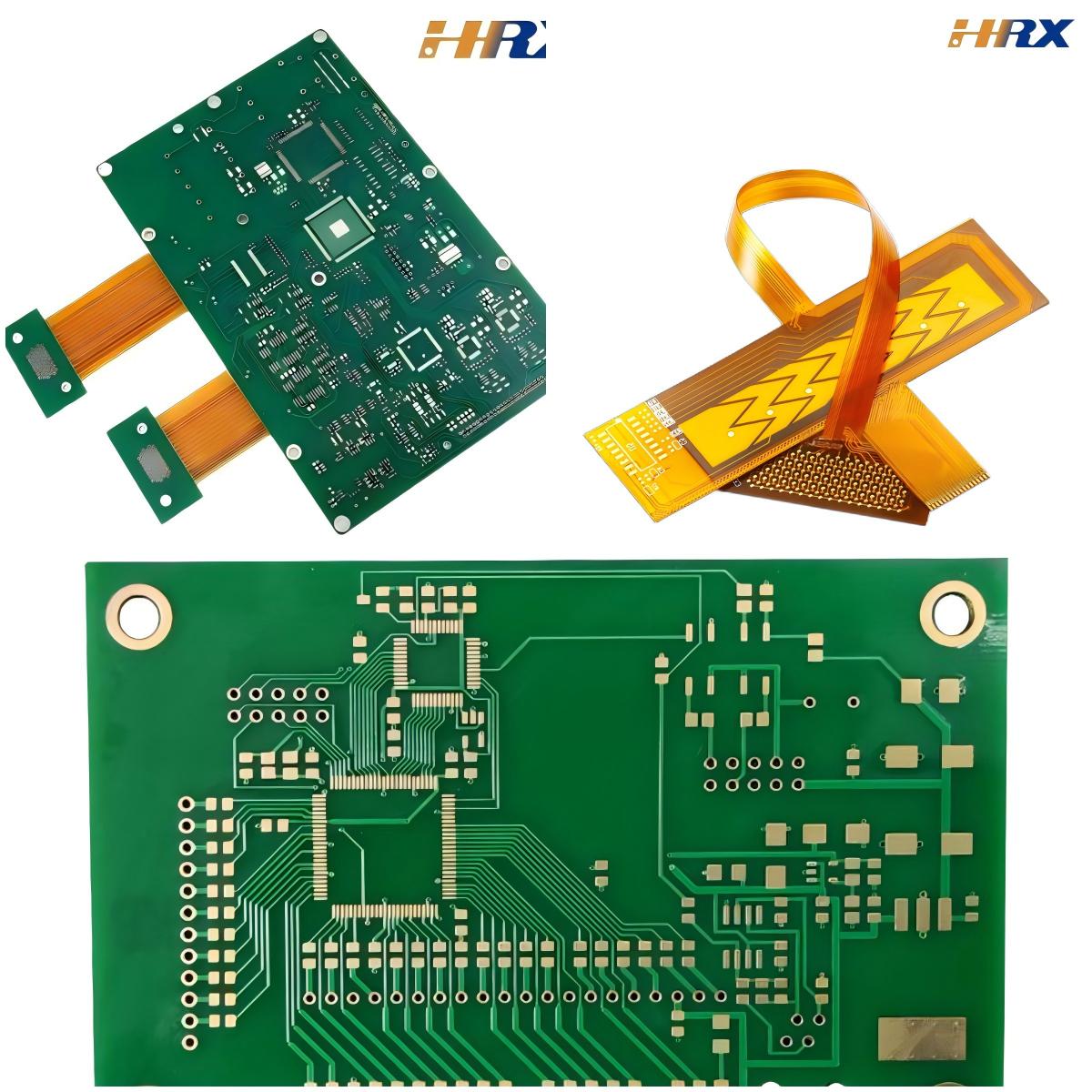

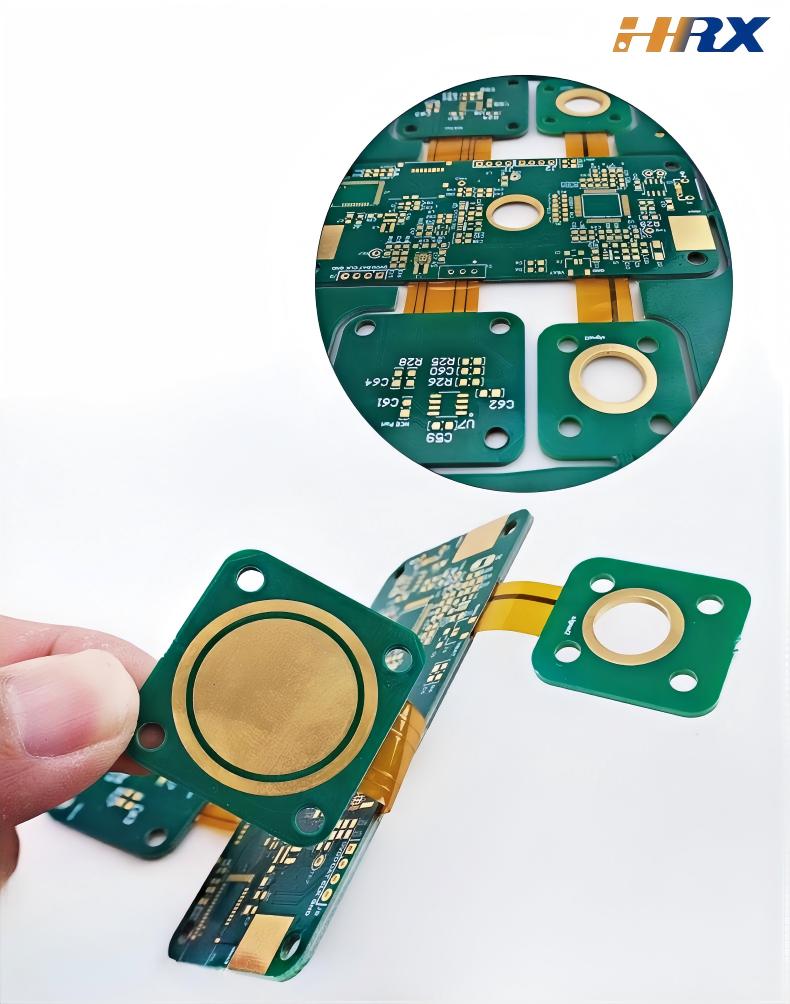

With the rapid expansion of the foldable smartphone market, Flexible Printed Circuits (FPC) have emerged as the "flexible neural network" that underpins the core functionality of these innovative devices. As a critical interconnect component, FPC enables seamless signal transmission and power supply between the foldable screen, motherboard, battery, and other modules during millions of folding cycles. However, the extreme operating conditions of foldable phones pose unprecedented challenges to FPC design and manufacturing. This blog delves into the key considerations for FPC in foldable smartphones and elaborates on how Shenzhen Huaruixin Electronics Co., Ltd., a global ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex boards, addresses these challenges to ensure product quality through cutting-edge technologies.

Key Design & Production Considerations for FPC in Foldable Phones

Foldable phones demand FPCs with exceptional flex durability, miniaturization, and signal integrity, far exceeding the requirements of traditional consumer electronics. The following are the core challenges and critical considerations in design and production:

1. Ultra-High Flex Durability Requirements

Unlike standard FPCs that withstand 10,000-100,000 bending cycles, FPCs for foldable phones must endure 200,000+ folding cycles, with high-end models targeting 500,000-1,000,000 cycles. Additionally, the bending radius is minimized to 0.3mm-0.5mm to accommodate the slim design of foldable devices, placing immense stress on materials and structures. Key considerations include selecting fatigue-resistant materials and optimizing structural design to disperse stress.

2. Signal Integrity in Dynamic Bending

Foldable phones require FPCs to transmit high-definition display signals and high-speed data (e.g., 5G, UWB) without attenuation or distortion during folding. The dynamic bending process can alter impedance and cause signal interference. Critical design considerations include using low-loss substrates, optimizing trace routing, and implementing impedance matching technologies. For 5G millimeter-wave applications, substrates with low dielectric constant (Dk), such as Liquid Crystal Polymer (LCP), are preferred to reduce signal loss.

3. Miniaturization and Space Optimization

The compact internal space of foldable phones demands FPCs with high wiring density and ultra-thin profiles. Trace widths and spacing as small as 0.05mm are often required, along with miniaturized connectors (e.g., 0.2mm pitch FPC connectors). Production considerations include precision etching and cutting technologies to ensure dimensional accuracy and avoid short circuits caused by burrs.

4. Environmental Adaptability and Reliability

FPCs in foldable phones must withstand extreme temperature fluctuations (-30℃ to 85℃), high humidity, and wear. Core considerations include applying protective coatings, selecting moisture-resistant materials, and conducting rigorous environmental testing to ensure stable performance under harsh conditions.

Shenzhen Huaruixin's Solutions: Quality Assurance & Core Technologies

As a professional ODM/OEM manufacturer with global reach, Shenzhen Huaruixin Electronics integrates advanced materials, innovative design, and precision manufacturing to address the aforementioned challenges. Our comprehensive quality control system and core technologies ensure the reliability and performance of FPCs for foldable phones.

1. High-Performance Material Selection and Customization

We prioritize material innovation to enhance FPC durability and performance:

- Ultra-Thin High-Toughness PI Substrates: We adopt 25μm-50μm modified polyimide (PI) substrates with excellent flexibility and fatigue resistance, ensuring no permanent deformation after millions of folds.

- High-Purity Rolled Copper Foil: Using 99.9%+ high-purity rolled copper with tightly arranged grains, the flex fatigue resistance is significantly improved, enabling up to 1,000,000 bending cycles—10 times higher than ordinary electrolytic copper.

- Adhesive-Free Cover Layers: Replacing traditional adhesive cover layers with adhesive-free ones reduces thickness and avoids adhesive aging and detachment during folding, enhancing long-term reliability.

2. Innovative Structural Design and Simulation Optimization

Our engineering team employs advanced design strategies and simulation tools to optimize FPC performance:

- Serpentine Routing Design: The flexible hinge area adopts serpentine (spring-like) routing to absorb tensile and compressive stresses during folding, minimizing trace fatigue. All trace corners are designed with 0.1mm micro-arcs to avoid stress concentration.

- Finite Element Analysis (FEA) Simulation: We use FEA to simulate stress distribution during folding, identifying potential failure points in advance and optimizing design parameters. This ensures the FPC can withstand extreme bending conditions while maintaining structural integrity.

- Multi-Layer Rigid-Flex Integration: For complex foldable phone modules, we integrate rigid and flexible layers to balance flexibility and structural support. For example, rigid sections are used for component mounting, while flexible sections handle bending, optimizing space utilization and reliability.

3. Precision Manufacturing Processes

We employ state-of-the-art manufacturing technologies to ensure high precision and consistency:

- Laser Cutting Technology: Replacing traditional mold stamping with laser cutting achieves precision up to ±0.01mm, enabling complex serpentine routing and smooth edges without burrs. This reduces short-circuit risks and improves product yield.

- Nano Nickel-Gold Plating: Trace surfaces are plated with nano-scale nickel-gold (several microns thick) to ensure excellent conductivity, wear resistance, and corrosion resistance without compromising flexibility.

- Automated Production and Inspection: We utilize fully automated SMT assembly lines and Automated Optical Inspection (AOI) systems to reduce human error. AOI detects solder defects, trace misalignment, and surface scratches with high accuracy, ensuring consistent quality.

4. Rigorous Quality Testing and Reliability Verification

Our quality control system adheres to international standards (IEC 61230, etc.), with comprehensive testing throughout the production process:

- Dynamic Flex Testing: Using advanced FPC bending test chambers, we simulate real-world folding conditions (1-60 cycles/min, 0.3mm-0.5mm bending radius) to verify durability up to 1,000,000 cycles. Real-time monitoring of resistance changes (accuracy 0.1mΩ) ensures electrical stability.

- Environmental Testing: Thermal cycling (-40℃ to 85℃), damp heat (85% RH at 85℃ for 1000 hours), and salt spray testing ensure the FPC adapts to harsh environments.

- Electrical Performance Testing: High-voltage (500V-1500V) insulation testing, continuity testing, and impedance testing (using Time-Domain Reflectometry, TDR) ensure signal integrity and electrical safety.

Conclusion

The successful application of FPC in foldable phones relies on overcoming rigorous challenges in flex durability, signal integrity, miniaturization, and reliability. Shenzhen Huaruixin Electronics addresses these challenges through advanced material selection, innovative design, precision manufacturing, and rigorous testing, delivering high-quality FPC solutions for global foldable phone manufacturers.

If you have project requirements, we, as a professional manufacturer, welcome you to contact us at any time. For more industry knowledge, you can also visit our website: www.hrxfpc.com or email us at sales@hrxfpc.com for consultation, exchange, learning, and guidance.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP