Search

The Role of Selective Laser Soldering in FPC, PCB, and Rigid-Flex Board Manufacturing: Benefits, Key Considerations, and Industry Expertise

- Nov 10,2025

-

Share

Why Selective Laser Soldering Emerges in FPC, PCB, and Rigid-Flex Board Fields

1.1 Limitations of Traditional Soldering Methods

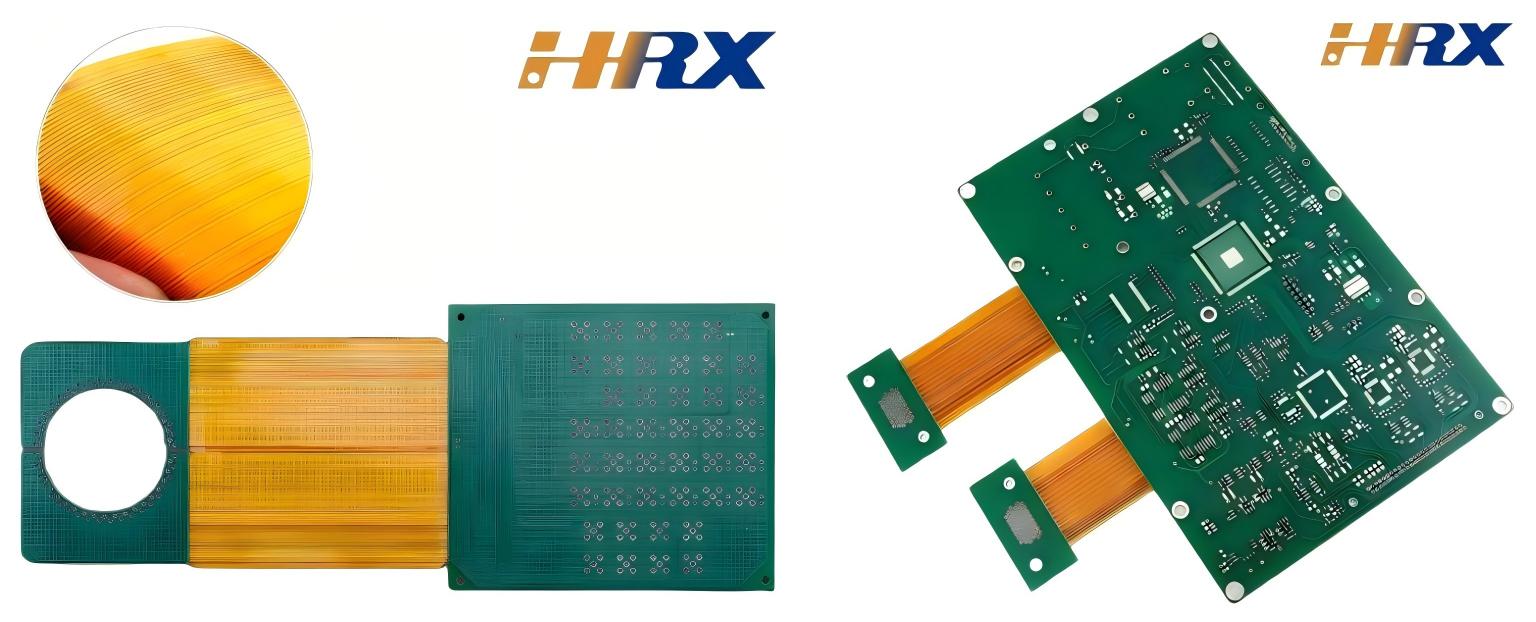

Conventional soldering techniques like wave soldering or manual soldering pose challenges in modern electronic manufacturing, especially with the miniaturization and complexity of FPC (Flexible Printed Circuits), PCB (Printed Circuit Boards), and rigid-flex boards. These methods often result in excessive heat exposure to surrounding components, leading to thermal stress, solder bridging, or damage to heat-sensitive materials like polyimide in FPCs. For instance, soldering tiny components on high-density PCBs or delicate flexible layers in rigid-flex boards with manual tools is prone to human error and inconsistent quality.

1.2 Technological Advancements Driving Demand for Precision

Selective laser soldering addresses these issues by leveraging high-energy laser beams to deliver precise, localized heat to specific solder joints. This non-contact process minimizes thermal impact to a radius as small as 50μm, making it ideal for intricate layouts where components are spaced as closely as 0.3mm. In rigid-flex boards, which combine fragile flexible layers with rigid structural sections, laser soldering ensures that only the target area is heated, preserving the integrity of the bendable regions and preventing delamination.

2. Key Benefits of Selective Laser Soldering for Product Performance

2.1 Enhanced Reliability in High-Reliability Applications

By reducing thermal stress on components and substrates, selective laser soldering improves joint durability, particularly in dynamic environments. For example, in automotive FPCs used in dashboard displays or ADAS sensors, which undergo constant vibration and temperature fluctuations, laser-soldered joints exhibit 30% fewer failures compared to conventional methods over 10,000 hours of operation. The process also eliminates mechanical stress from soldering irons, crucial for fragile components like 0201-sized resistors or fine-pitch BGA packages.

2.2 Enabling Miniaturization and Design Flexibility

In consumer electronics such as foldable smartphones or wireless earbuds, space constraints demand ultra-compact assemblies. Selective laser soldering allows soldering components on both sides of FPCs with as little as 0.1mm clearance, enabling 30% more component density. In rigid-flex boards for medical devices like endoscopes, the process facilitates soldering within tight 3D spaces, where traditional tools cannot reach, ensuring seamless integration of flexible cable sections with rigid control modules.

2.3 Cost-Efficiency in Complex Assemblies

While initial equipment costs are higher, selective laser soldering reduces rework rates by up to 70% in complex boards with mixed SMD and THT components. Its precision eliminates the need for costly masking or reflow oven adjustments for small batches, making it economical for low-volume, high-mix production—common in aerospace or industrial control applications where each board may have unique soldering requirements.

3. Critical Considerations in Design and Production for Optimal Results

3.1 Material Compatibility and Thermal Management

Designers must ensure that substrate materials (e.g., FR-4 for PCBs, PI for FPCs) and solder pastes (e.g., Sn-Ag-Cu for lead-free applications) are compatible with laser soldering’s rapid heating (100°C/ms) and cooling rates. For example, in a rigid-flex board design for a wearable device, using a low-temperature solder alloy (melting point <200°C) prevents overheating the flexible PI layer, while thermal vias in the rigid section dissipate excess heat to avoid delamination. Shenzhen Huaruixin Electronics Co., Ltd., a globally recognized ODM/OEM manufacturer in FPC, PCB, and rigid-flex board fields, has in - depth expertise in material selection. With its GB/T19001 - 2016/ISO 9001:2015 quality management system certification, IAF international recognition, and CNAS national recognition, the company can precisely match materials according to different product requirements, ensuring long - term stability under the harsh conditions of laser soldering.

3.2 Pad Design and Alignment Precision

Soldering pads for laser processes require precise dimensions (±5μm tolerance) and surface finishes (e.g., ENIG or OSP) to ensure consistent solder wetting. A case study in a high - frequency PCB for 5G modules showed that pads with rounded corners (instead of sharp edges) reduced solder ball formation by 40%. Additionally, using fiducial marks for automated laser alignment ensures a positional accuracy of ±25μm, critical for bonding 0.4mm pitch QFP packages on flexible substrates. Huaruixin Electronics has advanced design and manufacturing capabilities. Their experienced engineering team can design pads with high - precision dimensions, and the company's state - of - the - art equipment ensures accurate alignment during the laser soldering process, effectively reducing the occurrence of solder defects and improving product quality.

3.3 Process Parameter Optimization

Key parameters like laser power (5 - 50W), exposure time (50 - 500ms), and focal distance must be optimized for each joint type. In a FPC assembly with 50μm - thick copper traces, excessive laser power can cause trace burnout, while insufficient power leads to cold joints. Manufacturers use AOI (Automated Optical Inspection) to monitor joint morphology, ensuring solder fillets meet IPC - A - 610 Class 3 standards for mission - critical applications. Shenzhen Huaruixin Electronics Co., Ltd. has a professional R & D team that is proficient in optimizing laser soldering process parameters. They can quickly adjust parameters according to different product requirements and use advanced AOI equipment to strictly control product quality, ensuring that each product meets high - quality standards.

4. Shenzhen Huaruixin Electronics: A Trusted Partner in Advanced Electronics Manufacturing

As a globally recognized ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex boards, Shenzhen Huaruixin Electronics brings unmatched expertise in selective laser soldering and advanced interconnect solutions. Our advantages include:

Certified Quality Assurance: With ISO 9001:2015 and CNAS - certified quality systems, we ensure rigorous process control, from the meticulous material sourcing stage to the final inspection. This strict quality management system enables us to deliver products that meet the highest international standards, providing customers with reliable and consistent quality.

Technological Proficiency: Equipped with state - of - the - art laser soldering systems, we are capable of handling 0.3mm pitch components and 0.1mm - thick FPCs with precision. Our advanced equipment and technical know - how support complex geometries required in industries such as automotive, medical, and consumer electronics, allowing us to meet the diverse needs of different applications.

Design - for - Manufacturing (DFM) Expertise: Our experienced engineering team provides upfront DFM feedback. By optimizing pad layouts, material selection, and soldering parameters, we can reduce prototyping cycles by 20%. This not only speeds up the product development process but also helps to avoid potential manufacturing issues, saving both time and cost for our customers.

End - to - End Capabilities: Our integrated services encompass PCB fabrication, FPC lamination, rigid - flex assembly, and selective laser soldering. This comprehensive service portfolio ensures seamless process integration and traceability throughout the manufacturing process. Customers can enjoy one - stop solutions, simplifying the supply chain and enhancing overall efficiency.

5. Partner with Huaruixin for Your Next Project

Whether you're developing a high - reliability automotive control unit, a compact wearable device, or a sophisticated industrial PCB, Shenzhen Huaruixin Electronics Co., Ltd. has the expertise and capabilities to deliver superior results.

Contact Us: For project inquiries or technical discussions, reach out to our team at sales@hrxfpc.com or visit our website www.hrxfpc.com to explore our solutions. Our dedicated customer service representatives are always ready to answer your questions and provide detailed information about our services, from initial design consultations to final product delivery.

Industry Resources: Download our free whitepaper on “Best Practices for Selective Laser Soldering in Rigid - Flex Boards” on our website. This whitepaper is filled with in - depth knowledge, case studies, and practical tips accumulated from our years of experience in the field. It can serve as a valuable resource for engineers, designers, and manufacturers looking to optimize their laser soldering processes. Additionally, subscribe to our blog for the latest trends in advanced electronics manufacturing. We regularly update our blog with articles on emerging technologies, new material innovations, and industry - changing developments, ensuring that you stay ahead of the curve in the fast - paced world of electronics manufacturing.

By combining cutting - edge technology with decades of industry experience, we help you overcome design challenges, enhance product performance, and bring innovative electronics to market faster. Our commitment to quality, precision, and customer satisfaction makes us the ideal partner for all your FPC, PCB, and rigid - flex board manufacturing needs.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP