Search

The Indispensable Role of Precision Equipment in FPC Manufacturing

- May 05,2025

-

Share

In the rapidly advancing realm of electronics manufacturing, Flexible Printed Circuits (FPCs) have become integral to the creation of modern, high-performance devices. As a leading global ODM/OEM manufacturer specializing in FPCs, PCBs, and Rigid-Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. possesses in - depth expertise in leveraging precision equipment to drive innovation and quality in FPC production.

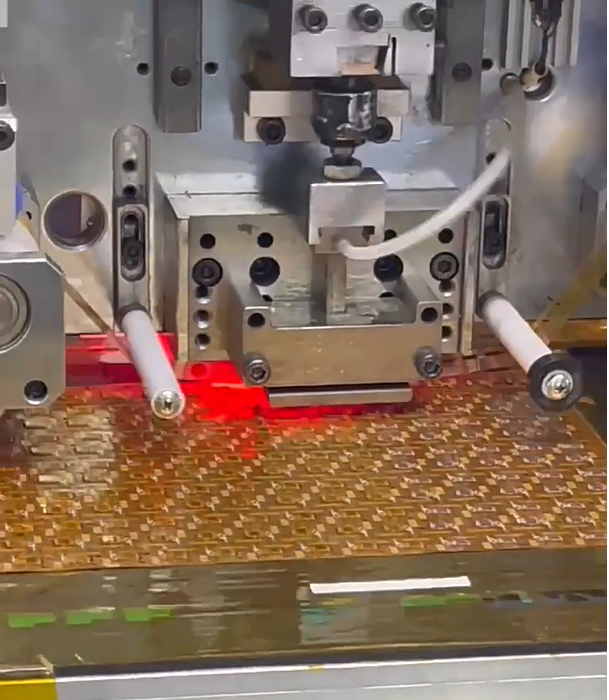

Unmatched Precision in Feature Fabrication

Precision equipment is the linchpin of FPC production, especially when dealing with intricate design elements. FPCs often feature ultra - fine line widths (down to 20μm or less) and spaces, as well as advanced structures like blind vias and microvias. High - precision laser cutting systems, for instance, are capable of achieving sub - micron accuracy during the circuit patterning process. This level of precision is crucial for creating high - density interconnect (HDI) FPCs, which are increasingly in demand for applications in smartphones, wearables, and medical devices. By utilizing state - of - the - art imaging systems with resolutions of up to 5000dpi, Shenzhen Huaruixin Electronics ensures that every FPC adheres to the strictest design tolerances, minimizing the occurrence of short circuits and open circuits.

Enhanced Production Efficiency

Automated precision equipment significantly boosts production efficiency in FPC manufacturing. Robotic pick - and - place machines, for example, can handle the placement of surface - mount devices (SMDs) on FPCs with speed and accuracy, reducing assembly time by up to 40%. Additionally, computer - controlled etching systems optimize the removal of copper layers, ensuring consistent results across large production batches. These advanced machines are equipped with real - time monitoring systems that adjust parameters such as temperature, pressure, and chemical concentration, maximizing yield rates. Shenzhen Huaruixin Electronics’ large - scale manufacturing facilities are outfitted with fully automated production lines, enabling the company to deliver high - quality FPCs in a timely manner, even for high - volume orders.

Quality Assurance and Reliability

Precision equipment is essential for ensuring the reliability of FPCs, particularly those used in critical applications. In aerospace and automotive electronics, where FPCs are exposed to extreme conditions, non - destructive testing (NDT) equipment such as X - ray inspection systems plays a vital role. These systems can detect internal defects, such as voids in vias or delamination between layers, without damaging the FPC. Shenzhen Huaruixin Electronics employs a comprehensive quality control process that includes in - line inspection using high - magnification microscopes and automated optical inspection (AOI) systems. This multi - tiered approach ensures that only FPCs meeting the highest standards of quality and reliability are shipped to customers.

Technological Innovation and Adaptability

The electronics industry is constantly evolving, and FPC manufacturers need to stay ahead of the curve. Precision equipment allows companies like Shenzhen Huaruixin Electronics to adapt to emerging trends, such as the demand for flexible and stretchable FPCs. Advanced additive manufacturing techniques, enabled by precision 3D printers, are being explored for creating customized FPCs with unique geometries. Moreover, the integration of artificial intelligence (AI) and machine learning (ML) algorithms into precision equipment enables predictive maintenance, reducing downtime and optimizing performance. By investing in cutting - edge precision equipment, Shenzhen Huaruixin Electronics is well - positioned to meet the future needs of the FPC market.

In conclusion, precision equipment is not just a tool but a strategic asset in FPC manufacturing. Shenzhen Huaruixin Electronics Co., Ltd.’s commitment to utilizing the latest precision equipment underscores its dedication to delivering top - notch FPC products. As the demand for smaller, more powerful, and reliable electronic devices continues to rise, the role of precision equipment in FPC production will only become more critical. Manufacturers that prioritize investment in precision technology will undoubtedly gain a competitive edge in this dynamic industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP