Search

Rigid-Flex PCB Design, Manufacturing & Inspection: Key Insights for Industry Excellence

- Jul 21,2025

-

Share

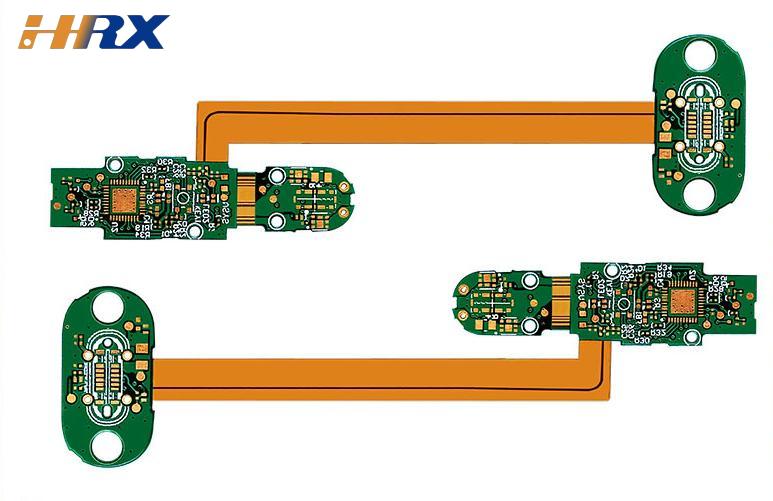

In the dynamic landscape of electronic interconnect solutions, Rigid-Flex Printed Circuits stand as a pinnacle of engineering innovation, merging the structural robustness of rigid PCBs with the adaptability of Flexible Printed Circuits (FPC). These hybrid assemblies—integrating polyimide (PI) substrates, adhesive-backed copper (ABC), and rigid FR-4 sections—have become indispensable in compact, high-reliability electronics spanning aerospace, medical devices, and consumer tech.

As a globally recognized ODM/OEM manufacturer, Shenzhen Huaruixin Electronics Co., Ltd. brings decades of specialized expertise in FPC, PCB, and rigid-flex solutions, offering unparalleled insights into navigating the complexities of these advanced interconnect systems.

Critical Design Parameters for High-Performance Rigid-Flex PCBs

Successful rigid-flex PCB implementation begins with meticulous design engineering, addressing unique challenges that distinguish these assemblies from traditional rigid or flexible circuits.

Material Selection & Compatibility

Material compatibility ranks foremost—selecting compatible dielectrics (PI, PET) and conductive layers (rolled annealed copper, electrodeposited copper) ensures reliable interlayer adhesion and mechanical performance during dynamic flexing. Huaruixin’s engineering team specializes in material science optimization, leveraging proprietary databases to match substrate combinations with application-specific requirements, from -55°C to 125°C operating ranges.

Mechanical Integrity Engineering

Bend radius engineering: Critical for fatigue resistance in dynamic applications requiring 10,000+ flex cycles. Maintaining a minimum bend radius of 10x the total thickness of the flexible section prevents conductor cracking—a parameter strictly monitored in Huaruixin’s DFM (Design for Manufacturability) reviews.

Coverlay alignment: Laser-cut coverlays with ±0.02mm positional accuracy prevent solder bridging during assembly.

Stiffener placement: Strategic integration addresses mechanical stability in high-vibration environments.

Signal Integrity Optimization

Signal integrity demands special attention in high-frequency rigid-flex designs. Controlled impedance management across rigid-flex transitions—achieved through precise dielectric thickness control and trace geometry optimization—ensures consistent performance up to 40GHz in Huaruixin’s advanced designs. Thermal management features, including embedded heat spreaders, address heat dissipation in power-sensitive applications.

Advanced Manufacturing Considerations for Rigid-Flex PCBs

Transitioning from design to production requires specialized manufacturing capabilities to handle the hybrid nature of rigid-flex circuits.

Precision Lamination Processes

Sequential lamination—a core competency at Huaruixin’s ISO 9001-certified facilities—enables precise bonding of rigid and flexible sections without compromising layer registration. Utilizing advanced vacuum lamination presses with programmable temperature profiles (180-220°C) ensures void-free adhesion between dissimilar materials, critical for long-term reliability.

Microvia Formation & Drilling

Laser drilling has revolutionized via formation in rigid-flex PCBs. Huaruixin employs UV laser systems to create microvias (50-100μm diameter) with aspect ratios up to 1:1.5 in flexible sections, eliminating mechanical drilling limitations. This precision enables higher component density while maintaining flexibility—a key advantage in wearable technology and IoT devices.

Plating & Surface Finishes

Plating processes must accommodate both rigid and flexible substrates. Huaruixin’s proprietary pulse plating techniques ensure uniform copper thickness (18-70μm) across rigid and flexible regions, with ENIG (Electroless Nickel Immersion Gold) finishes providing excellent solderability and corrosion resistance for harsh environments. Automated optical inspection (AOI) systems integrated throughout production detect anomalies like underplating or excessive solder mask pullback in real-time.

Rigorous Quality Inspection Protocols

Quality assurance in rigid-flex PCB production demands multi-layered inspection methodologies addressing both rigid and flexible characteristics.

Electrical Testing

Flying probe testing: Verifies net connectivity and continuity across complex layouts.

ICT (In-Circuit Testing): Deployed for high-volume production to ensure consistent electrical performance.

Impedance testing: Uses time-domain reflectometry (TDR) to verify controlled impedance values within ±10% tolerance.

Mechanical & Environmental Validation

Peel strength testing: Ensures minimum 0.8N/mm adhesion per IPC-2223 standards.

Flex endurance testing: Simulates 100,000+ flex cycles at specified radii to validate long-term reliability.

Microsection analysis: Under digital microscopy inspects interlayer bonds and via quality.

Environmental qualification: Includes thermal cycling (-55°C to +125°C) and vibration testing (20-2,000Hz) for critical applications.

Shenzhen Huaruixin Electronics: A Legacy of Rigid-Flex Excellence

With over 15 years of dedicated experience in FPC and rigid-flex manufacturing, Shenzhen Huaruixin Electronics Co., Ltd. embodies the pinnacle of industry expertise. Our 10,000㎡ manufacturing facility—equipped with 50+ advanced production lines—delivers 500,000+ rigid-flex PCBs monthly, serving clients across automotive, telecommunications, and industrial sectors.

Our engineering team, comprising 30+ specialists with average 8+ years of experience, provides end-to-end support from initial design feasibility through prototyping and mass production. This technical prowess, combined with our commitment to ISO, UL, and RoHS compliance, ensures that every Huaruixin rigid-flex PCB meets the most stringent global standards.

Partner With Industry Leaders

If your project requires high-performance rigid-flex PCBs or custom FPC solutions, Shenzhen Huaruixin Electronics stands ready as your trusted manufacturing partner. Our technical sales team is available to discuss your specific requirements, offering tailored solutions to meet your application’s unique challenges.

For comprehensive industry insights, visit our knowledge hub at www.hrxfpc.com. To discuss your project or request a quotation, contact our sales team directly at sales@hrxfpc.com. Let’s collaborate to bring your next innovation to life—with the reliability and performance that only decades of specialized expertise can deliver.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP