Search

Polyimide: The Pivotal Substrate in Flexible Printed Circuits (FPC) – Properties, Design Essentials & Huaruixin’s Expertise

- Jul 11,2025

-

Share

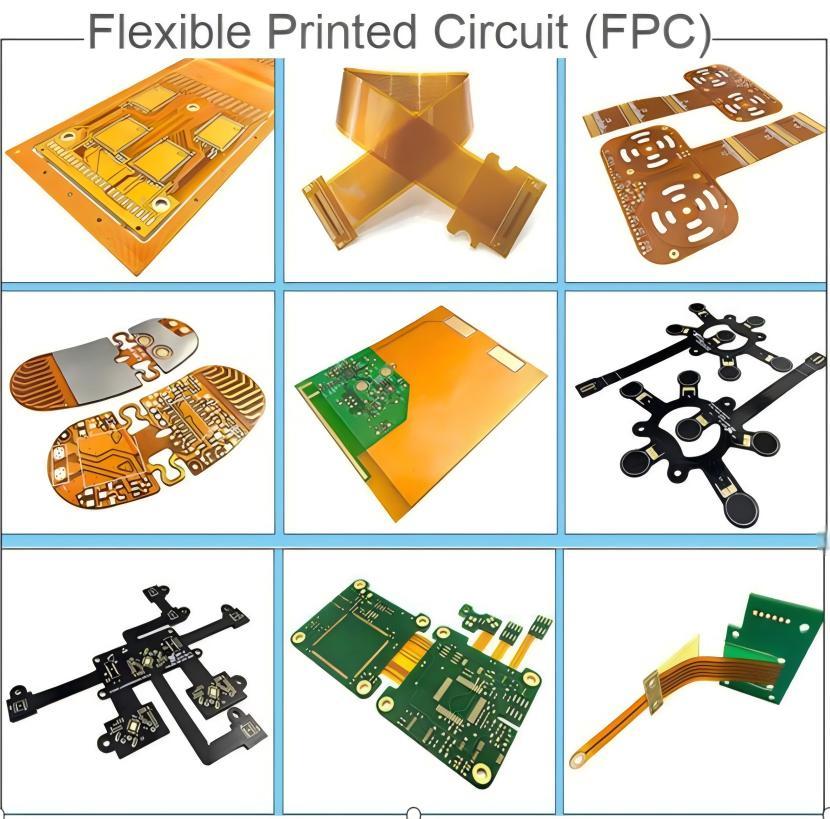

In the dynamic landscape of flexible electronics, Flexible Printed Circuits (FPC) serve as the critical connective tissue, enabling innovation in industries ranging from consumer electronics to aerospace. At the heart of high-performance FPC lies Polyimide (PI), a material whose unique properties have solidified its status as the substrate of choice for demanding applications. As a leading global ODM/OEM manufacturer of FPC, PCB, and rigid-flex boards, Shenzhen Huaruixin Electronics Co., Ltd. (Huaruixin) leverages Polyimide’s capabilities to deliver cutting-edge solutions. This blog delves into Polyimide’s defining characteristics, key considerations in FPC design and manufacturing, and Huaruixin’s technical insights—essential reading for engineers and procurement professionals seeking reliable FPC partners.

Key Properties of Polyimide: Why It’s Indispensable for FPC

Polyimide’s dominance in FPC substrates stems from a synergistic blend of attributes that address the core challenges of flexible electronics:

Exceptional Thermal Endurance: With a continuous operating temperature range of -269°C to 400°C, Polyimide outperforms alternatives like PET in high-heat environments. This makes it ideal for FPCs in automotive engine bays, LED lighting modules, and industrial control systems.

Superior Electrical Insulation: Boasting a dielectric constant (Dk) of 3.0–4.0 at 10 GHz and low dielectric loss (tanδ < 0.005), Polyimide minimizes signal attenuation and crosstalk. For 5G FPC antennas, IoT device interconnects, and high-speed data links, this translates to unmatched signal integrity—a non-negotiable in today’s data-driven world.

Mechanical Resilience: Polyimide films exhibit high tensile strength (150–200 MPa) and elongation at break (50–100%), enabling FPCs to withstand thousands of flex cycles without fatigue. This flexibility is pivotal for foldable smartphones, wearable fitness trackers, and medical devices requiring conformal fitting.

Chemical and Environmental Stability: Resistant to solvents, acids, and UV radiation, Polyimide ensures FPC longevity in harsh conditions—from sterilized medical equipment to marine electronics. Its inherent flame retardancy (UL94 V-0) eliminates the need for harmful additives.

Critical Design & Production Considerations for Polyimide FPCs

Harnessing Polyimide’s potential requires precision in design and manufacturing. At Huaruixin, we prioritize these factors to ensure flawless FPC performance:

Material Specification: Polyimide thickness (12.5μm–125μm) directly impacts flexibility and rigidity. For wearables, 12.5–25μm films balance flexibility and durability; for rigid-flex boards, 50–125μm layers provide structural support. Our engineers conduct FEA simulations to validate thickness choices for each application.

Adhesion Engineering: Polyimide’s low surface energy demands specialized treatment (plasma activation, chemical priming) to ensure strong bonding with copper foils. We use adhesive-free copper-clad Polyimide (CCL) for high-reliability applications like aerospace FPCs, eliminating delamination risks.

Precision Etching: Achieving fine-pitch traces (≤50μm) on Polyimide requires controlled etching. Our laser direct imaging (LDI) and alkaline etching processes maintain ±3μm tolerance, critical for miniaturized FPCs in camera modules and microelectronics.

Thermal Management During Lamination: Polyimide’s high Tg (>250°C) necessitates precise temperature profiling during multi-layer lamination. Our vacuum lamination systems ensure uniform pressure (1–5 MPa) and heat distribution, preventing warpage in high-density FPCs.

Testing Protocols: We subject Polyimide FPCs to rigorous reliability tests—including thermal cycling (-55°C to 125°C, 1000 cycles), flex testing (100,000+ bends), and moisture resistance (85°C/85% RH, 1000 hours)—to validate performance in real-world conditions.

Huaruixin’s Vision: Advancing Polyimide FPC Technology

As a full-service ODM/OEM with large-scale manufacturing capabilities, Shenzhen Huaruixin Electronics integrates Polyimide innovation into every stage of FPC development:

Custom Material Solutions: We collaborate with global Polyimide suppliers to develop proprietary grades—such as low-Dk PI for 6G prototypes and flame-retardant PI for automotive ADAS systems—tailored to client needs.

Smart Manufacturing Integration: Our Industry 4.0 facilities use AI-driven quality control to monitor Polyimide thickness, copper adhesion, and etching precision in real time, ensuring 99.9% yield rates for mass production.

Sustainability in Production: We adopt eco-friendly Polyimide formulations and water-based processes to reduce carbon footprint, aligning with global green manufacturing standards .

Partner with Huaruixin for Your Polyimide FPC Projects

Whether you’re designing flexible sensors, high-frequency communication modules, or rigid-flex assemblies, Polyimide-based FPCs are the key to unlocking innovation. As a trusted manufacturer with decades of expertise, Huaruixin delivers end-to-end solutions—from material selection to mass production—backed by rigorous quality assurance.

For project inquiries, technical collaborations, or to learn more about Polyimide FPC technology, visit our website at www.hrxfpc.com or contact our team at sales@hrxfpc.com. Let’s engineer the future of flexible electronics together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP