Search

Polyimide (PI) in FPC, PCB & Rigid-Flex Boards: Key Traits, Advantages, Quality Focus & Industry Insights

- Nov 06,2025

-

Share

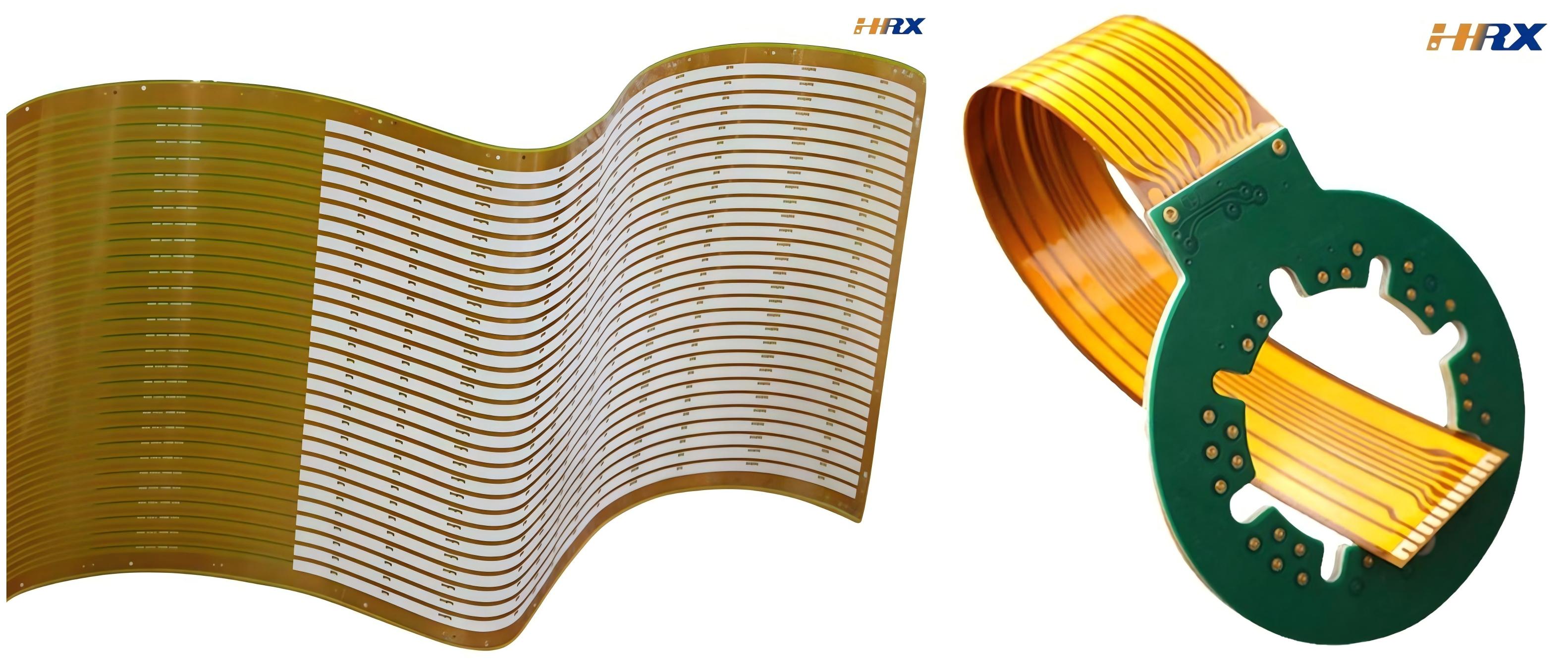

Polyimide (PI) has become an irreplaceable core material in the flexible electronics industry, especially for Flexible Printed Circuits (FPC), Printed Circuit Boards (PCB), and rigid-flex boards. Its unique performance characteristics perfectly align with the demands of high-reliability, miniaturized, and high-temperature-resistant electronic products. As a global ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex boards, Shenzhen Huaruixin Electronics Co., Ltd. holds GB/T19001-2016/ISO 9001:2015 quality management system certification, along with IAF international accreditation and CNAS national recognition. This article delves into PI’s specific traits, application advantages, critical quality control points in design and production, and industry priorities—while highlighting Huaruixin Electronics’ professional strengths in leveraging PI for high-performance circuit solutions.

1. Core Traits & Advantages of Polyimide (PI) in FPC/PCB/Rigid-Flex Boards

PI’s dominance in flexible and rigid-flex circuit applications stems from its unmatched material properties, tailored to the industry’s most stringent requirements:

Exceptional Thermal Stability: Withstands continuous operating temperatures of -269°C to 280°C and short-term exposure to 400°C. This makes PI-based FPC/PCB ideal for high-temperature environments like automotive electronics, aerospace systems, and industrial control units.

Superior Flexibility & Durability: PI films exhibit excellent bending resistance (up to 100,000+ flex cycles) and mechanical strength, enabling tight folding and repeated motion in compact devices (e.g., smartphones, wearables, medical equipment). Rigid-flex boards using PI substrates maintain structural integrity while adapting to complex device geometries.

Excellent Electrical Insulation: PI offers high dielectric strength (≥300 kV/mm) and low dielectric constant (2.8–3.4 at 1 MHz), ensuring signal integrity and reducing crosstalk in high-frequency applications (5G communication, IoT modules, and high-speed data transmission).

Chemical & Environmental Resistance: PI is resistant to solvents, oils, humidity, and radiation, enhancing the long-term reliability of FPC/PCB in harsh operating conditions (outdoor electronics, marine equipment, and medical implants).

Low Outgassing & Dimensional Stability: PI’s minimal outgassing under vacuum and low coefficient of thermal expansion (CTE: 10–20 ppm/°C) prevent warping or deformation during soldering and high-temperature processing, critical for precision rigid-flex board assembly.

2. Critical Quality Control Points in PI-Based FPC/PCB/Rigid-Flex Production

While PI’s properties are advantageous, strict quality management is essential to maximize performance—an area where Huaruixin Electronics excels due to its certified quality system:

Material Selection & Sourcing: Ensure PI films meet industry standards (e.g., Dupont Kapton®, Toray Upilex®) with consistent thickness (12.5–125 μm) and purity. Huaruixin’s rigorous supplier audit process guarantees high-quality PI substrates for every project.

Thermal Processing Precision: Control curing temperatures (200–350°C) and dwell times during lamination and soldering to avoid PI degradation. Overheating can reduce flexibility or cause delamination, so Huaruixin uses advanced thermal profiling equipment for real-time process monitoring.

Adhesion & Bonding Strength: Use compatible adhesives (e.g., PI-based or epoxy adhesives) to ensure strong bonding between PI layers, copper foils, and rigid substrates in rigid-flex boards. Huaruixin conducts peel strength tests (≥0.8 N/mm) to validate adhesion reliability.

Dimensional Accuracy: Mitigate PI’s CTE mismatch with copper by optimizing circuit design (compensation for thermal expansion) and using precision etching (±0.01 mm tolerance). This prevents misalignment during assembly, a common issue in high-density PI FPC.

Surface Treatment & Cleanliness: Remove contaminants (dust, oil, or residual chemicals) from PI surfaces before copper plating or lamination. Huaruixin’s Class 1000 cleanroom production environment minimizes particle contamination, ensuring consistent conductivity and insulation.

Reliability Testing: Perform accelerated aging tests (temperature cycling, humidity testing, flex endurance) and electrical performance checks (dielectric breakdown, signal loss) to validate PI-based FPC/PCB durability. Huaruixin’s ISO 9001-certified quality system mandates 100% batch testing for critical applications.

3. Industry Focus: Key Trends Driving PI Adoption in FPC/PCB

The growing demand for high-performance, miniaturized, and reliable electronics is amplifying PI’s role in three core industry segments—where Huaruixin Electronics delivers targeted solutions:

5G & High-Speed Electronics: 5G devices require FPC with low signal loss and high-frequency performance. PI’s low dielectric constant makes it the material of choice for antenna flex cables and high-speed data lines. Huaruixin’s PI-based FPC supports data rates up to 10 Gbps, meeting 5G infrastructure and consumer electronics needs.

Automotive Electronics: Electric vehicles (EVs) and advanced driver-assistance systems (ADAS) demand FPC/PCB that withstand extreme temperatures and vibration. PI’s thermal stability and durability make it ideal for battery management systems (BMS), in-vehicle infotainment, and sensor modules. Huaruixin’s automotive-grade PI FPC complies with IATF 16949 standards (pending full certification) for reliability.

Medical & Wearable Devices: Medical equipment (e.g., pacemakers, diagnostic tools) and wearables require biocompatible, flexible, and sterilizable components. PI’s chemical resistance and biocompatibility (meets ISO 10993 standards) make it suitable for implantable and portable medical devices. Huaruixin’s cleanroom production ensures PI FPC meets medical-grade purity requirements.

4. Huaruixin Electronics: Professional Advantages in PI-Based FPC/PCB/Rigid-Flex Solutions

As a certified ODM/OEM manufacturer, Huaruixin Electronics combines technical expertise, quality assurance, and industry experience to deliver PI-based circuit solutions:

Certified Quality Assurance: GB/T19001-2016/ISO 9001:2015 certification, IAF international recognition, and CNAS national accreditation validate our strict quality control processes—from PI material sourcing to final product delivery.

PI Application Expertise: Our engineering team specializes in optimizing PI-based designs for flexibility, thermal resistance, and signal integrity. We collaborate with clients to tailor FPC/PCB/rigid-flex solutions for specific industry needs (automotive, medical, 5G).

Advanced Production Capabilities: Class 1000 cleanrooms, precision etching equipment, thermal profiling systems, and reliability testing labs enable us to produce high-quality PI FPC/PCB with tight tolerances and consistent performance.

Global ODM/OEM Services: We support end-to-end solutions, including design optimization, prototyping, mass production, and logistics—catering to global clients in electronics, automotive, medical, and aerospace industries.

If you have a project requiring PI-based FPC, PCB, or rigid-flex boards, Huaruixin Electronics is your trusted professional manufacturer. Whether you need custom designs, technical support, or mass production, we are ready to collaborate. For more industry knowledge and product details, visit our website: www.hrxfpc.com or contact us via email: sales@hrxfpc.com to exchange insights and receive expert guidance.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP