Search

OSP Surface Treatment for FPC: Advantages, Applications & Expert Manufacturing Guide

- Sep 29,2025

-

Share

In the fast-paced world of flexible printed circuit (FPC) manufacturing, surface treatment of exposed copper features—including solder pads, connectors, and vias—directly determines product reliability and assembly yields. Exposed copper on FPCs, with their thin polyimide (PI) or polyester (PET) substrates, is exceptionally prone to oxidation, which degrades solderability and undermines electrical connectivity. Among surface treatment solutions, Organic Solderability Preservatives (OSP) has become a staple for high-precision FPCs, rigid-flex boards, and miniaturized electronic components. This guide unpacks OSP’s core benefits, limitations, key applications, and critical process controls, while introducing a trusted manufacturing partner for OSP-treated FPC solutions.

1. Core Advantages of OSP for FPC Surface Treatment

OSP delivers unique value for FPC production, aligning with demands for fine-pitch routing, cost efficiency, and environmental compliance:

Ultra-Thin Oxidation Barrier: OSP forms a uniform organic film (0.1–0.3μm thick, extendable to 0.5μm for enhanced protection) that adheres tightly to FPC copper surfaces. This barrier seals copper from moisture and oxygen without adding bulk, critical for FPCs with 30μm+ line-width/line-spacing (L/S) and 40μm+ microvias.

Lead-Free & RoHS-Compliant: As a halogen-free, lead-free technology, OSP meets global environmental standards (RoHS, REACH) essential for consumer electronics and automotive FPCs. It eliminates heavy metal waste associated with traditional hot-air solder leveling (HASL).

Cost Efficiency for High-Volume FPC Production: Compared to electroless nickel immersion gold (ENIG) or immersion silver (ImAg), OSP requires simpler processing equipment and lower material costs. This translates to 30–50% lower surface treatment expenses for mass-produced FPCs used in smartphones, wearables, and IoT devices.

Preserves FPC Dimensional Stability: The thin OSP film does not impact the flexibility or dimensional accuracy of PI-based FPCs. Unlike thicker metallic coatings, it avoids warpage during roll-to-roll (R2R) FPC manufacturing and maintains alignment for subsequent coverlay lamination and component assembly.

Optimized for Fine-Pitch FPCs: OSP’s smooth, flat surface supports precise solder paste deposition—critical for FPCs with 0.4mm pitch components (e.g., camera modules, battery connectors). Its minimal thickness ensures no interference with high-density interconnect (HDI) structures in folding-screen phone FPCs.

2. Key Limitations of OSP in FPC Applications

While advantageous, OSP has constraints that demand careful application planning for FPCs:

Limited Shelf Life & Handling Sensitivity: OSP-treated FPCs require strict storage (15–25°C, 30–60% RH) and have a typical shelf life of 6–12 months. Mechanical abrasion during rigid-flex board assembly or moisture absorption can damage the film, leading to copper oxidation and poor solder wetting.

Reflow Soldering Restrictions: OSP films decompose at high temperatures (typically >240°C), making them unsuitable for FPCs requiring multiple reflow cycles. Overheating causes film residue, which impairs solder joint formation in complex FPC assemblies like automotive infotainment modules.

Poor Harsh Environment Resistance: The organic film offers minimal protection against corrosive gases, extreme humidity, or temperature fluctuations. This rules out OSP for under-hood automotive FPCs or industrial sensors exposed to harsh conditions—where ENIG remains preferable.

Challenging Quality Inspection: OSP’s transparent/translucent appearance makes defects (pinholes, uneven coverage) undetectable to the naked eye. FPC manufacturers require automated optical inspection (AOI) systems calibrated for thin organic films to ensure consistency.

3. Primary Applications of OSP-Treated FPCs

OSP excels in applications where FPC miniaturization, cost, and environmental compliance are priorities:

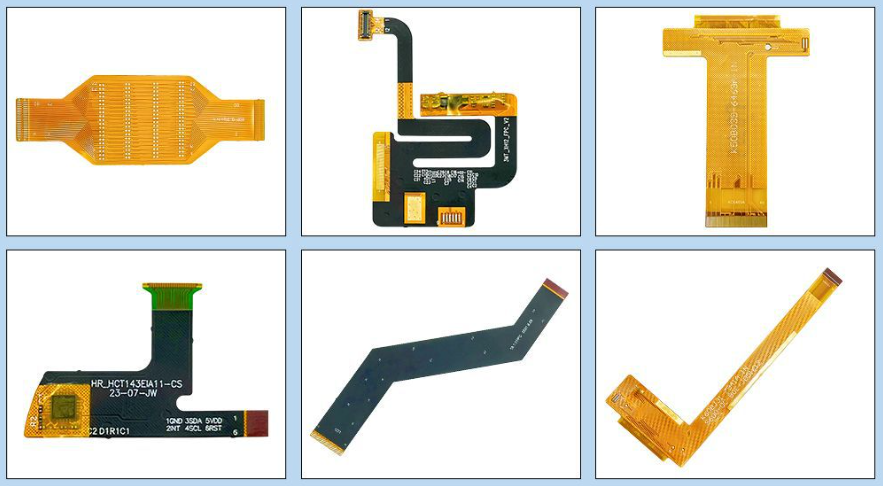

Consumer Electronics FPCs: OSP is the standard for smartphone FPCs (display modules, battery connectors, fingerprint sensors)—where 10–15 FPCs per device demand high precision and low cost. It also supports wearables (smartwatches, TWS earbuds) and foldable devices, where thin, flexible circuits are non-negotiable.

Non-Critical Automotive FPCs: In-car entertainment systems, instrument clusters, and body control modules rely on OSP-treated FPCs. These components operate in stable cabin environments and benefit from OSP’s cost efficiency versus ENIG.

IoT & Wearable Device FPCs: Low-power IoT sensors and portable medical monitors (e.g., basic heart rate trackers) use OSP FPCs to balance solderability, cost, and compact design. The lead-free formulation meets medical device regulatory requirements.

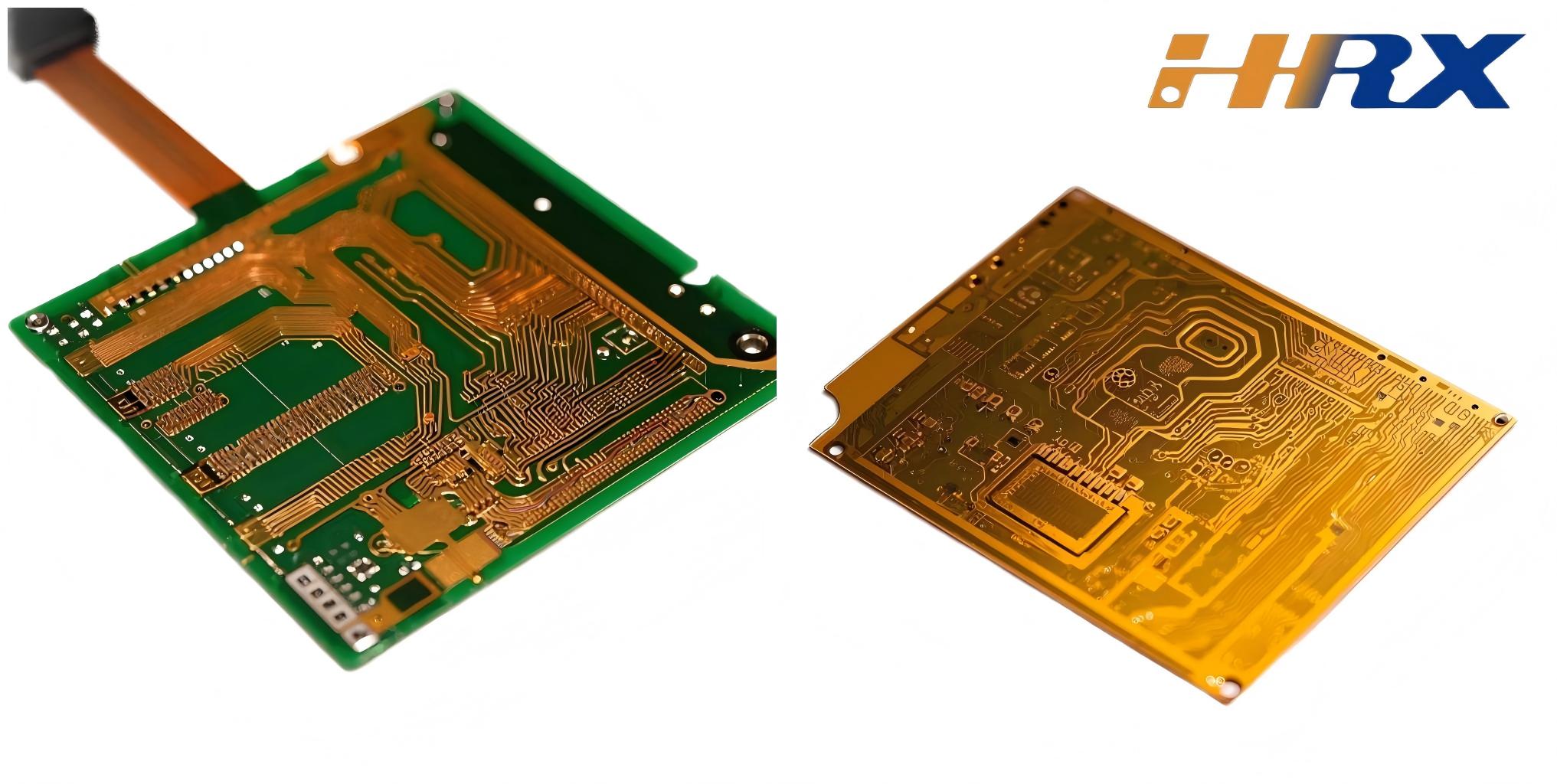

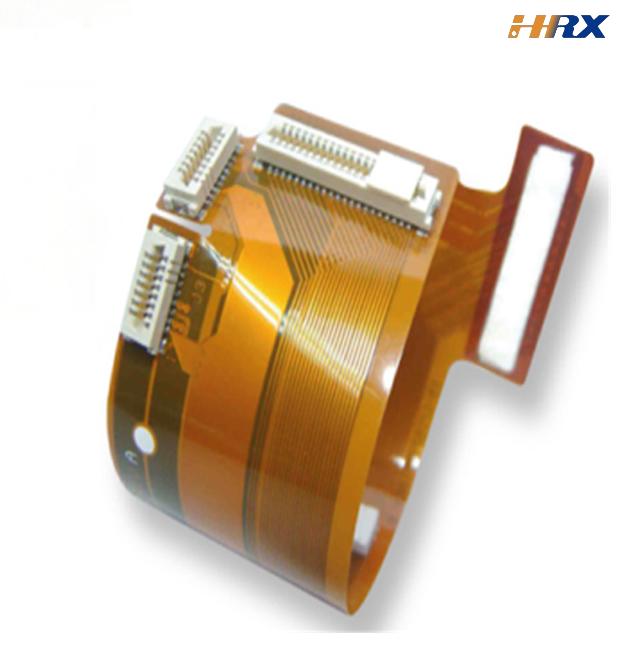

Rigid-Flex Board Interfaces: OSP protects copper pads on rigid-flex board flex regions, where thickness constraints prevent thicker coatings. It ensures reliable soldering of connectors between rigid PCB sections and flexible PI substrates.

4. Critical Process Controls for OSP on FPCs

Achieving reliable OSP performance requires rigorous process management tailored to FPC’s delicate substrates:

Precision Copper Pre-Treatment: FPC copper surfaces must undergo degreasing, micro-etching (to 1–2μm roughness), and activation before OSP application. Contaminants (oil, residual dry film) cause uneven film adhesion—critical for FPCs with narrow L/S ratios.

Film Thickness Calibration: For FPCs, OSP thickness is calibrated to 0.2–0.3μm (optimal for solderability). Thinner films fail to prevent oxidation; thicker films hinder solder wetting, especially on 0.3mm pitch pads. Process parameters (solution concentration, 30–40°C bath temperature) are monitored in real time.

Controlled Curing for Flexibility: Post-coating curing (100–120°C for 5–10 minutes) enhances film adhesion without embrittling PI substrates. Over-curing risks FPC flexibility loss, while under-curing leads to film peeling during bending.

Specialized FPC Storage & Handling: OSP-treated FPCs are sealed in anti-static, moisture-barrier bags with desiccants. They must be used within 48 hours of opening to avoid oxidation—critical for R2R-assembled FPC batches.

Reflow Profile Optimization: FPC assembly lines use OSP-specific reflow curves (peak temperature <245°C, dwell time <60s) to ensure film decomposition without damaging PI substrates or adhesive layers.

5. Trusted OSP FPC Manufacturer: Shenzhen Huaruixin Electronics Co., Ltd.

For high-quality OSP-treated FPCs, rigid-flex boards, and PCBs, Shenzhen Huaruixin Electronics Co., Ltd. stands as a global leader in ODM/OEM manufacturing. Our expertise addresses the unique challenges of OSP application for fine-pitch, flexible circuits.

Huaruixin operates a state-of-the-art manufacturing base equipped with R2R FPC production lines, automated OSP coating systems, and AOI inspection tools calibrated for thin organic films. Our engineering team specializes in optimizing OSP processes for FPCs with L/S down to 30μm and microvias as small as 40μm—meeting the demands of 5G and foldable device manufacturers.

Quality is embedded in our operations: we hold GB/T19001-2016/ISO 9001:2015 certification, IAF international accreditation, and CNAS national recognition. Every OSP-treated FPC undergoes rigorous testing—from film thickness verification to solderability validation—to ensure consistency. Whether you need OSP for consumer electronics FPCs or custom rigid-flex solutions, we deliver compliant, high-yield products that reduce your total manufacturing costs.

6. Contact Huaruixin for Your OSP FPC Needs

Ready to optimize your FPC production with reliable OSP surface treatment? Connect with our team today:

Website: Explore our FPC expertise and OSP capabilities at www.hrxfpc.com

Email: Send project specifications to sales@hrxfpc.com for a tailored quote. Our engineers are available to advise on OSP suitability for your FPC design and application.

Partner with Huaruixin to leverage industry-leading OSP technology for your flexible circuit projects—where precision, compliance, and cost efficiency drive success.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP