Search

OSP Surface Treatment for FPC: 4 Future Trends Shaping Flexible PCB Manufacturing (2025)

- Oct 07,2025

-

Share

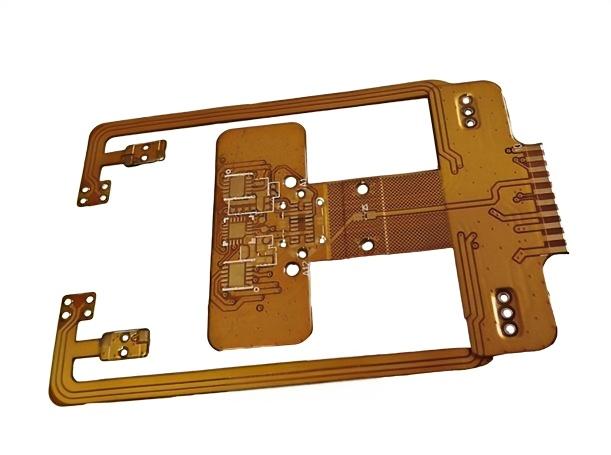

Organic Solderability Preservatives (OSP) has become the backbone of surface treatment for flexible printed circuits (FPC), rigid-flex PCBs, and high-density interconnect (HDI) boards—especially as 5G, automotive electronics, and wearable devices drive demand for thinner, more durable flexible substrates. For manufacturers and buyers seeking reliable OSP-coated FPC solutions, understanding industry evolution is critical. Below, we break down the top trends reshaping OSP technology, paired with insights from Shenzhen Huaruixin Electronics Co., Ltd., a globally accredited ODM/OEM specializing in FPC/PCB manufacturing.

1. Eco-Friendly OSP Formulations: Compliance with Global Green Standards

The most urgent trend in OSP technology is the shift to RoHS 2.0-compliant, low-VOC coatings—a response to tightening environmental regulations worldwide. Traditional OSP chemistries often contained volatile organic compounds that risked regulatory penalties, but next-generation formulations replace hazardous components with biodegradable alternatives while preserving solderability. For FPCs using flexible polyimide (PI) substrates, this means coatings that avoid chemical degradation of the base material while meeting REACH and California Prop 65 requirements .

Huaruixin’s Competitive Edge: Our ISO 9001:2015-certified (IAF/CNAS-accredited) manufacturing facilities integrate green OSP processing lines—from micro-etching to organic coating—that eliminate toxic residues. This ensures OSP-treated FPCs for medical wearables and consumer electronics pass global environmental audits, reducing our clients’ market access risks.

2. High-Performance OSP for Demanding FPC Applications

As FPCs enter harsh environments (e.g., automotive underhood systems, industrial sensors), OSP coatings are evolving to deliver enhanced thermal stability and moisture resistance. Key advancements include:

Coatings that withstand 3+ reflow soldering cycles (critical for multi-layer FPC assemblies)

Thin-film formulations (2–5μm) compatible with fine-pitch SMT (0.3mm pitch) and wire bonding

Thermal shock resistance (-40°C to 150°C) for automotive FPCs in engine compartments

Huaruixin’s Technical Capability: Our R&D team optimizes OSP thickness and adhesion for high-flex FPCs (up to 10,000 flex cycles) used in foldable phones. By tailoring coatings to match substrate rigidity (PI vs. PET), we ensure consistent solder joint integrity across rigid-flex PCB assemblies.

3. OSP Compatibility with Diverse FPC Substrates & Hybrid Processes

FPC manufacturers increasingly require OSP to coexist with other surface treatments (e.g., OSP + ENIG) for mixed-technology boards. Future OSP solutions will offer:

Customized chemistries for high-frequency FPC substrates (e.g., PTFE-based materials for 5G antennas)

Compatibility with selective OSP coating—targeting only solder pads while avoiding contact pads needing immersion gold

Improved adhesion to textured copper surfaces (common in flexible HDI FPCs)

Huaruixin’s Manufacturing Flexibility: Our automated lines support hybrid surface treatment workflows, applying OSP to solder regions and ENIG to connector areas on the same FPC. This eliminates process bottlenecks for clients building complex IoT devices with mixed interconnect needs.

4. Intelligent OSP Process Control for FPC Mass Production

Industry 4.0 is transforming OSP application through real-time quality monitoring and data-driven optimization. Leading manufacturers now use:

In-line sensors to measure OSP film thickness (preventing under-coating oxidation or over-coating solder defects)

MES (Manufacturing Execution Systems) to track coating parameters across FPC batches

AI algorithms that adjust immersion time based on substrate copper roughness

Huaruixin’s Smart Factory Advantage: Our digitalized OSP lines integrate 24/7 thickness testing and traceability—each FPC’s OSP process data is logged for 10+ years. This reduces defect rates to <0.01% for high-volume orders (e.g., 1M+ FPCs for smartwatches).

Partner with Huaruixin for OSP-Treated FPC Excellence

Whether you need OSP-coated FPCs for automotive radar modules, wearable biosensors, or rigid-flex PCBs, Huaruixin delivers solutions aligned with industry trends. Our combination of green manufacturing, application-specific R&D, and intelligent quality control ensures your products meet performance and compliance goals.

Explore our OSP and FPC technologies: www.hrxfpc.com

Request a custom quote or technical consultation: sales@hrxfpc.com

Stay ahead of FPC innovation—let’s collaborate.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP