Search

Multilayer FPC (6+ Layers): Structure, Design, Applications & Huaruixin's Expertise

- Jul 11,2025

-

Share

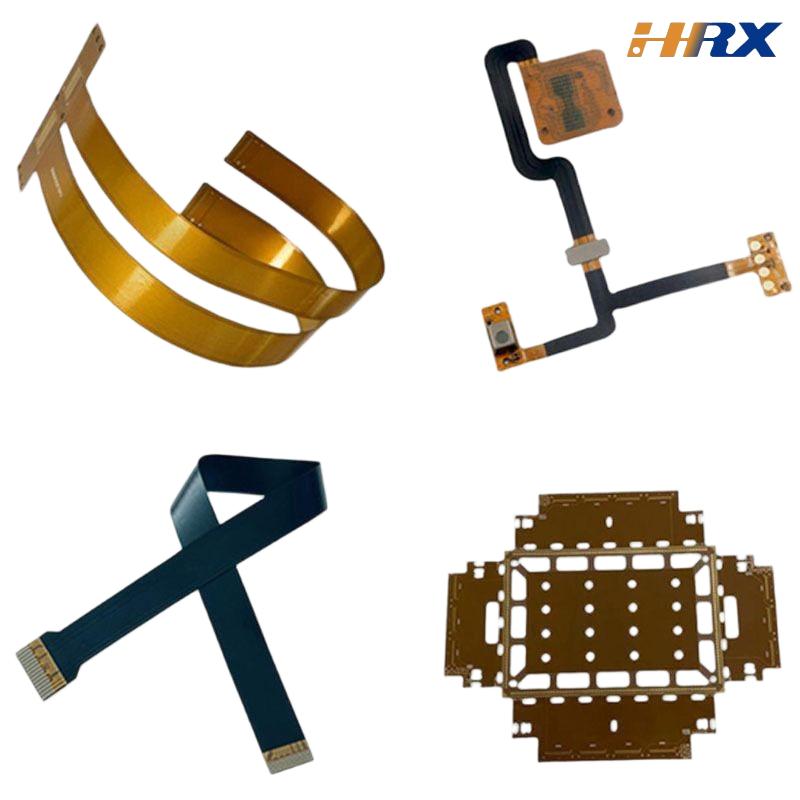

In the realm of advanced electronics, Flexible Printed Circuits (FPC) are revolutionizing device design, and Multilayer FPC (6 layers and above) are at the forefront of this innovation. As a critical component in high - density interconnect (HDI) applications, these flexible circuits play a pivotal role in modern electronics. Let's explore their core aspects with professional insights.

1. Structural Features of 6+ Layer Multilayer FPC

Conductive Layers: Comprising 6 or more layers of electrodeposited copper (ED copper) or rolled annealed copper (RA copper), these layers enable complex signal routing and power distribution. The increased layer count supports high - density interconnect (HDI) and fine - pitch routing, crucial for advanced electronics.

Dielectric Layers: Utilizing high - performance polyimide (PI) films as the base material, these layers provide excellent electrical insulation, thermal stability (up to 260°C), and flexural endurance. They are bonded with acrylic or epoxy adhesives (or adhesive - free PI for high - end applications) to ensure layer adhesion.

Coverlay & Solder Mask: A coverlay (PI with adhesive) or liquid photoimageable solder mask (LPI) protects the outer conductive layers, offering abrasion resistance and environmental protection against moisture and dust.

Via Structures: Incorporates through - hole vias (THV), blind vias, and buried vias for interlayer connectivity, enhancing design flexibility and signal integrity in 6+ layer configurations.

2. Critical Design & Manufacturing Considerations for Multilayer FPC

Design Factors:

Impedance Control: Precise calculation of characteristic impedance (50Ω, 75Ω, etc.) using tools like 3D EM simulation to ensure signal integrity in high - speed data transmission (e.g., USB 3.2, PCIe 4.0).

Stack - up Design: Optimal arrangement of signal layers, ground planes, and power planes to minimize crosstalk, EMI/EMC issues, and ensure thermal dissipation.

Flex Bend Radius: Adhering to minimum bend radius (typically 10x the thickness of the FPC) to prevent copper fatigue and insulation breakdown during repeated flexing.

Manufacturing Factors:

Lamination Process: Utilizing vacuum lamination with precise temperature and pressure control to avoid voids and ensure uniform adhesion between layers.

Laser Drilling: Employing UV laser drilling for microvias (down to 50μm) to achieve high density in 6+ layer FPC, critical for miniaturized devices.

Etching Precision: Advanced acid etching or plasma etching to maintain line width/space (L/S) as tight as 25μm/25μm, ensuring circuit accuracy.

AOI & AXI Inspection: Implementing Automated Optical Inspection and Automated X - ray Inspection to detect defects in inner and outer layers, ensuring high yield.

3. Key Application Fields of 6+ Layer Multilayer FPC

Consumer Electronics: Used in smartphones (for foldable displays, camera modules), wearables (smartwatches, fitness trackers), and AR/VR headsets, leveraging their high density and flexibility.

Automotive Electronics: Integrated into ADAS sensors, infotainment systems, and EV battery management systems (BMS), withstanding -40°C to 125°C operating temperatures and vibration.

Medical Devices: Applied in minimally invasive surgical tools, patient monitors, and implantable devices, due to biocompatibility (using medical - grade PI) and miniaturization.

Aerospace & Defense: Utilized in satellite communication systems, avionics, and military drones, offering lightweight design and resistance to extreme environments.

Shenzhen Huaruixin Electronics Co., Ltd.'s Technical Vision

As a leading global ODM/OEM manufacturer of FPC, PCB, and Rigid - Flex PCBs, Shenzhen Huaruixin Electronics Co., Ltd. excels in 6+ layer FPC innovation. Our state - of - the - art manufacturing facilities enable mass production of high - precision multilayer FPC with tight L/S, reliable impedance control, and excellent flex life.

We prioritize material science (adopting high - Tg PI and ultra - thin copper) and process engineering (implementing AI - driven quality control) to meet evolving industry demands. Our ODM/OEM capabilities allow customization for high - volume consumer electronics and low - volume, high - reliability aerospace projects.

For project inquiries, partner with a professional manufacturer—contact us today. Explore more industry insights at www.hrxfpc.com or email sales@hrxfpc.com to collaborate, learn, and innovate together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP