Search

Mastering FPC Reinforcement Material Selection: A Comprehensive Guide for Optimal Performance

- May 08,2025

-

Share

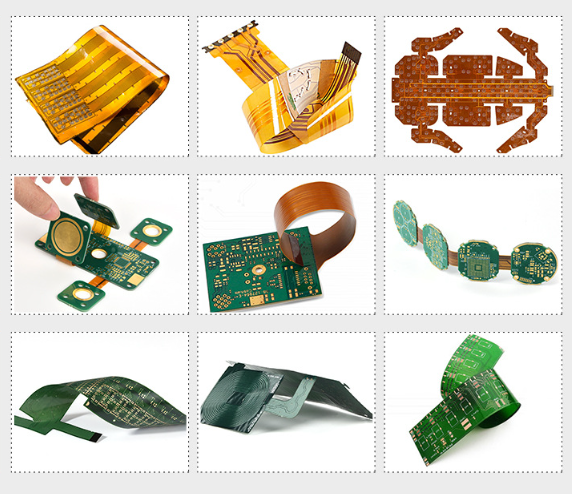

In the intricate landscape of flexible printed circuit (FPC) technology, the strategic selection of reinforcement materials is a linchpin for ensuring superior performance, durability, and reliability. As a leading global ODM/OEM manufacturer specializing in the design, development, and large-scale production of FPCs, PCBs, and rigid-flex printed boards, Shenzhen Huaruixin Electronics Co., Ltd. brings unparalleled expertise to the table. Our extensive experience in the FPC manufacturing domain equips us with in-depth knowledge of the diverse reinforcement materials available, enabling us to offer tailored solutions that meet the exacting demands of our clients across various industries.

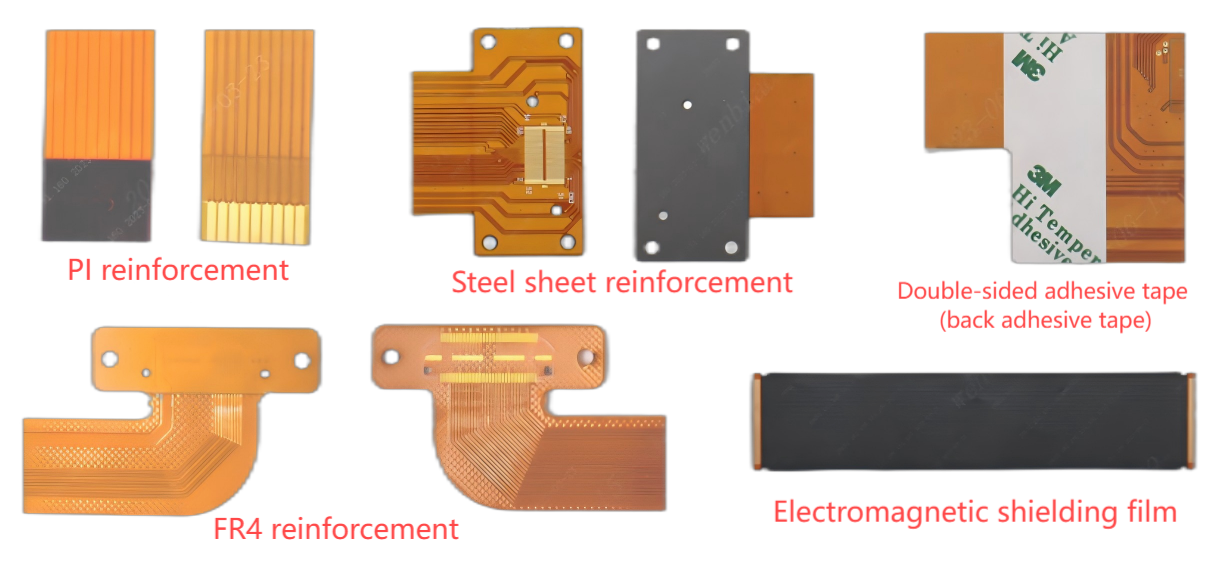

Key FPC Reinforcement Materials and Their Attributes

1. PI Reinforcement (Polyimide)

Polyimide, a high-performance engineering polymer, is renowned for its exceptional thermal stability, making it an ideal choice for applications involving high-temperature soldering processes, such as reflow soldering and wave soldering. With a glass transition temperature (Tg) often exceeding 300°C, PI reinforcement ensures that FPCs can withstand the rigors of harsh thermal environments without compromising structural integrity. At Shenzhen Huaruixin Electronics Co., Ltd., we frequently recommend PI reinforcement for high-reliability applications in automotive electronics, aerospace, and industrial control systems, where resistance to thermal cycling and long-term stability are critical.

Its excellent chemical resistance to a wide range of solvents, acids, and alkalis further enhances its suitability for harsh operating conditions. Additionally, PI's inherent flexibility allows for seamless integration with FPC substrates, typically made of the same material, ensuring excellent bendability and conformability. This property is particularly valuable in applications where the FPC needs to be flexed repeatedly, such as in wearable devices and foldable electronics.

2. FR-4 Reinforcement (Fiberglass Epoxy)

FR-4, a composite material consisting of glass fiber fabric impregnated with epoxy resin, is widely used for its high mechanical strength and rigidity. It offers excellent dimensional stability, making it an ideal choice for reinforcing areas of FPCs that require robust support, such as connector interfaces and areas subject to mechanical stress. The high modulus of FR-4 provides excellent resistance to bending and twisting, ensuring that the FPC maintains its shape and functionality even under demanding operating conditions.

With a Tg typically ranging from 130°C to 150°C, FR-4 reinforcement can withstand the temperatures encountered during most soldering processes. At Shenzhen Huaruixin Electronics Co., Ltd., we leverage the properties of FR-4 to enhance the mechanical performance of FPCs in applications such as industrial automation, medical devices, and telecommunications equipment, where reliability and durability are paramount.

3. Stainless Steel Reinforcement

Stainless steel reinforcement offers unrivaled mechanical strength and durability, making it suitable for applications that demand extreme robustness and resistance to wear and tear. Its high tensile strength and hardness provide excellent support for FPCs in heavy-duty environments, such as those found in industrial machinery, military equipment, and automotive powertrain systems.

In addition to its mechanical properties, stainless steel exhibits excellent corrosion resistance, making it suitable for use in harsh environments with high humidity, chemical exposure, or saltwater ingress. At Shenzhen Huaruixin Electronics Co., Ltd., we have extensive experience in integrating stainless steel reinforcement into FPCs for applications where reliability and longevity are non-negotiable.

4. Aluminum Reinforcement

Aluminum reinforcement combines good mechanical strength with lightweight properties, making it an attractive option for applications where weight reduction is a priority. Its high thermal conductivity also makes it an excellent choice for applications that require efficient heat dissipation, such as LED lighting, power electronics, and automotive battery management systems.

The corrosion resistance of aluminum can be further enhanced through surface treatments such as anodizing, providing additional protection against environmental factors. At Shenzhen Huaruixin Electronics Co., Ltd., we utilize aluminum reinforcement to optimize the performance of FPCs in applications where a balance between mechanical strength, thermal management, and weight is essential.

5. PET Reinforcement (Polyethylene Terephthalate)

PET is a cost-effective and lightweight reinforcement material commonly used in applications where moderate mechanical strength and flexibility are required. With a lower Tg compared to PI and FR-4, PET is suitable for applications that do not involve high-temperature processing or operation. Its good chemical resistance and ease of processing make it a popular choice for consumer electronics, such as smartphones, tablets, and smartwatches, where cost and weight are critical factors.

At Shenzhen Huaruixin Electronics Co., Ltd., we leverage the affordability and versatility of PET reinforcement to provide cost-effective solutions for our clients in the consumer electronics industry, without compromising on quality or performance.

6. Acrylic Reinforcement

Acrylic reinforcement offers a combination of flexibility, transparency, and ease of processing, making it suitable for applications that require aesthetic appeal and design flexibility. Its low cost and good chemical resistance make it a popular choice for consumer products, such as wearable devices, digital signage, and point-of-sale displays.

At Shenzhen Huaruixin Electronics Co., Ltd., we utilize acrylic reinforcement to create innovative and visually appealing FPC solutions that meet the evolving needs of our clients in the consumer electronics and signage industries.

Critical Considerations in FPC Reinforcement Material Selection

1. Mechanical Strength Requirements

The mechanical strength requirements of an FPC application are a primary determinant in the selection of reinforcement material. For applications that involve high mechanical loads, such as those in industrial machinery or automotive components, materials with high tensile strength and rigidity, such as stainless steel, FR-4, or aluminum, are preferred. At Shenzhen Huaruixin Electronics Co., Ltd., our engineering team conducts detailed mechanical analysis and simulations to ensure that the selected reinforcement material can withstand the expected forces and stresses, providing optimal performance and reliability.

2. Thermal Performance

Thermal performance is another critical factor, especially in applications involving high-temperature soldering or operation in elevated temperature environments. Materials with high thermal stability, such as PI and FR-4, are recommended for such applications. Our expertise in thermal management allows us to select the most suitable reinforcement material based on the specific thermal requirements of the FPC, ensuring that it can withstand the thermal cycling and operating temperatures without degradation.

3. Flexibility and Bendability

In applications where the FPC needs to be flexed or bent repeatedly, such as in wearable devices or foldable electronics, flexibility is a key consideration. Materials like PI and PET offer excellent bendability and conformability, making them suitable for these applications. Our design engineers take into account the required flexibility and bend radius of the FPC when selecting the reinforcement material, ensuring that it does not compromise the overall flexibility and performance of the product.

4. Cost Constraints

Cost is often a significant factor in the selection of reinforcement material, especially in price-sensitive markets such as consumer electronics. Materials like PET and acrylic offer a cost-effective solution without sacrificing essential performance characteristics. At Shenzhen Huaruixin Electronics Co., Ltd., we work closely with our clients to understand their cost constraints and develop customized solutions that balance cost, performance, and quality.

5. Environmental Conditions

The operating environment of the FPC also plays a crucial role in material selection. In harsh environments with high humidity, chemical exposure, or saltwater ingress, materials with excellent corrosion resistance, such as stainless steel, PI, or aluminum with appropriate surface treatment, are recommended. Our experience in developing FPCs for a wide range of industries enables us to select the most suitable reinforcement material based on the specific environmental conditions of the application, ensuring long-term reliability and performance.

Why Choose Shenzhen Huaruixin Electronics Co., Ltd.?

With our state-of-the-art manufacturing facilities, advanced production processes, and a team of highly skilled engineers, Shenzhen Huaruixin Electronics Co., Ltd. is committed to delivering high-quality FPC solutions that meet the highest industry standards. Our extensive experience in FPC reinforcement material selection and application allows us to provide customized solutions that are tailored to the unique requirements of each client.

We invite you to explore our comprehensive range of FPC, PCB, and rigid-flex printed board solutions at www.hrxfpc.com. For more information or to discuss your specific project requirements, please contact our sales team at sales@hrxfpc.com. Let us partner with you to create innovative and reliable FPC solutions that drive your business forward.

#FPC #FlexiblePrintedCircuit #FPCReinforcement #ReinforcementMaterials #PCB #RigidFlexPrintedBoard #ShenzhenHuaruixinElectronics

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP