Search

Laser Direct Imaging (LDI) Technology in FPC/PCB/Rigid-Flex Boards: Features, Performance Impact & Expert Applications

- Nov 08,2025

-

Share

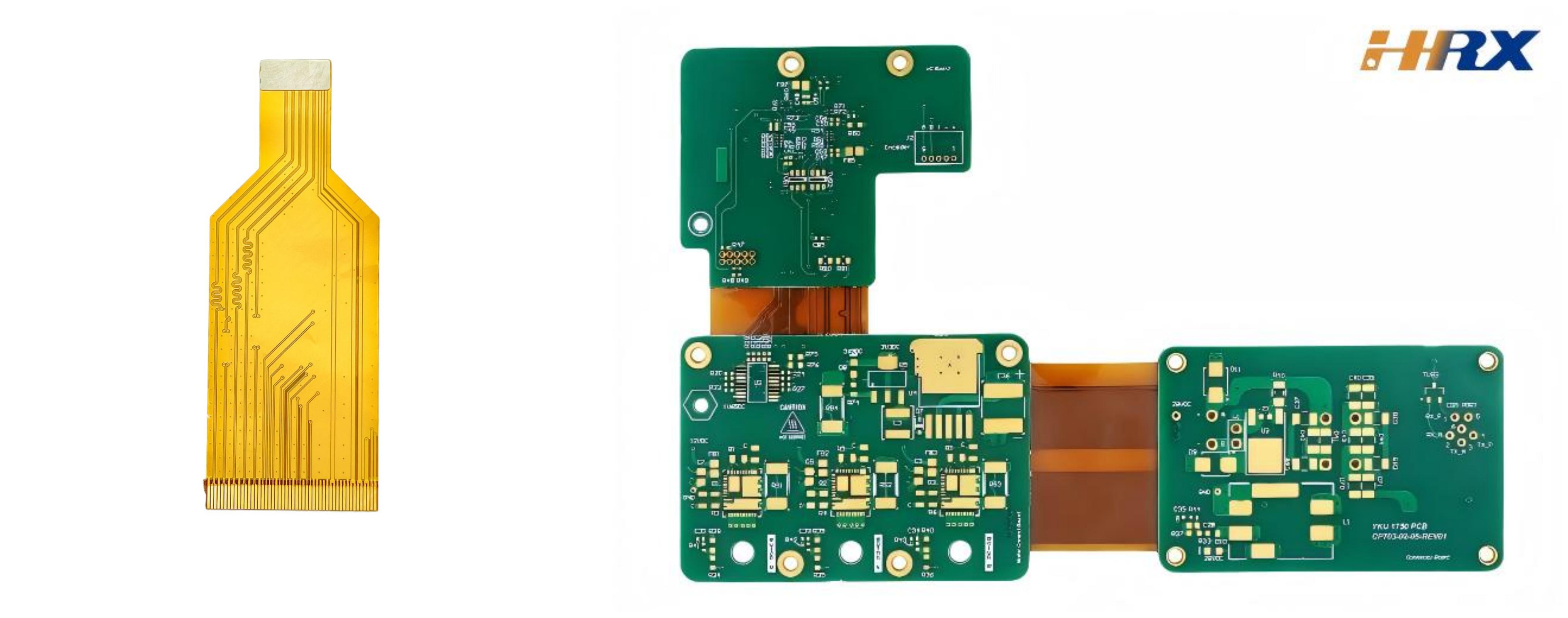

As electronic devices trend toward miniaturization, high density, and multi-functionality, Laser Direct Imaging (LDI) has emerged as a core manufacturing technology reshaping the FPC, PCB, and rigid-flex board industries. This article dives into LDI’s key application features, performance benefits, target sectors, and critical considerations in design, production, and quality control—while highlighting how Shenzhen Huaruixin Electronics Co., Ltd. leverages this technology to deliver premium ODM/OEM solutions.

Core Application Features of LDI Technology in FPC/PCB/Rigid-Flex Boards

LDI technology stands out for its digital-driven advantages that address the limitations of traditional photolithography, especially for high-precision requirements:

Ultra-high precision & resolution: Achieves minimum line width down to 5μm and registration accuracy of ±5μm, supporting fine line spacing as tight as 38μm (1.5mil) for 1/3 oz copper substrates. This outperforms traditional processes (±15~20μm accuracy) for HDI (High-Density Interconnect) designs.

Maskless efficiency: Eliminates photomask production and modification costs, cutting tooling lead time from 4 hours to 30 minutes. Ideal for custom projects, small-batch production, and rapid prototyping.

Superior consistency: Digital laser scanning reduces defects from mask aging, contamination, or distortion, boosting yield rates by 3-5% compared to conventional methods.

Broad material compatibility: Works with dry film, liquid photoimageable resist (LPI), and advanced substrates like Rogers (for high-frequency applications) and ABF (for IC substrates).

Scalable throughput: Multi-beam LDI systems achieve 200 hits/hr or 40 panels/hour, balancing precision with mass production needs.

How LDI Technology Enhances Product Performance

LDI directly elevates FPC/PCB/rigid-flex board performance by optimizing structural and electrical properties:

Higher interconnect density: Enables line width/spacing ≤25μm for 5G millimeter-wave antenna boards, supporting 77GHz signal transmission with minimal loss.

Reduced signal crosstalk: Precise line spacing control (per IPC-2221 standards) minimizes electromagnetic interference (EMI), critical for high-speed data transmission in consumer electronics and automotive systems.

Enhanced reliability: Eliminates contact-related defects (e.g., scratches, contamination) from traditional masks, improving thermal stability (-40℃ to 150℃ operating range) for automotive and aerospace applications.

Improved yield & cost-efficiency: HDI board yields rise from 96% to 99.3%, while batch-to-batch variation drops by 75%, reducing rework and total production costs.

Key Application Fields for LDI-Enabled FPC/PCB/Rigid-Flex Boards

LDI’s precision and flexibility make it indispensable across high-value electronic sectors:

Consumer Electronics: Smartphones (flexible inner connectors), OLED displays (fine electrode patterns), and wearables—where miniaturization and high-density wiring are non-negotiable.

Automotive Electronics: ADAS (Advanced Driver Assistance Systems) sensors, in-vehicle infotainment screens (OLDI/LVDS interfaces), and battery management systems (BMS)—requiring long-term reliability (≥15 years) and extreme temperature resistance.

Medical Devices: Implantable monitors and diagnostic equipment, where micro-scale, biocompatible FPCs demand ultra-precise circuitry and zero defects.

Aerospace & Defense: Satellite communication modules and avionics—benefiting from LDI’s high consistency and resistance to harsh environments.

IC Packaging Substrates: Chiplet and 2.5D/3D packaging substrates, supporting line widths of 10-15μm and aspect ratios ≥1:1.

Critical Considerations in Design, Production & Quality Control

To maximize LDI’s benefits, manufacturers must address material, process, and inspection challenges:

Design Phase

Match substrate thermal expansion coefficient (CTE) with component CTE (e.g., AlN ceramic substrates for silicon chip compatibility) to avoid solder fatigue.

Limit line density to manufacturer capabilities (e.g., ≤30μm line width for mass production) and use simulation tools (HyperLynx, Ansys SIwave) for signal integrity analysis.

Incorporate clear fiducial marks for LDI’s optical alignment system, ensuring ±12μm layer-to-layer registration.

Production Phase

Optimize laser parameters: Adjust 355nm/405nm wavelength, power density (50-500mW/cm²), and exposure time (30-40s per 18”×24” panel) based on photoresist type.

Control environmental conditions: Maintain cleanroom class 10,000+, temperature 22±1℃, and humidity 50±5% to prevent substrate warpage.

Conduct preventive maintenance: Calibrate laser optics monthly and monitor OEE (Overall Equipment Efficiency) to keep availability ≥98%.

Quality Control Phase

Deploy AOI (Automated Optical Inspection) systems integrated with LDI data for real-time defect detection (e.g., line discontinuities, spacing violations).

Verify dimensional accuracy with coordinate measuring machines (CMM) to ensure line width tolerance ±10%.

Perform reliability tests: Thermal cycling (-40℃ to 150℃) and humidity aging for automotive/industrial products, ensuring CPK ≥1.8.

Shenzhen Huaruixin Electronics: LDI Expertise Backed by Global Certifications

Shenzhen Huaruixin Electronics Co., Ltd. is a global ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex boards—with core strengths in LDI-enabled high-precision manufacturing:

Certified Quality Assurance: Fully compliant with GB/T19001-2016/ISO 9001:2015, IAF international accreditation, and CNAS national recognition, ensuring rigorous process control from design to delivery.

Advanced LDI Production Capacity: Equipped with multi-beam LDI systems (355nm/405nm wavelength) supporting 5μm line width and 610×710mm panel sizes, capable of mass-producing HDI boards, fine-line FPCs, and complex rigid-flex solutions.

Engineering Expertise: In-house R&D team optimizes LDI parameters for diverse substrates (e.g., Rogers, PTFE, liquid crystal polymer) and collaborates with clients on design for manufacturability (DFM) to avoid common pitfalls.

Cross-Industry Experience: Proven track record serving consumer electronics, automotive, medical, and aerospace clients—delivering LDI-enabled products with 99.3%+ yield and on-time delivery rate ≥98%.

Customization Capabilities: Flexible ODM/OEM services adapt to small-batch prototyping and large-scale production, leveraging LDI’s maskless advantage to reduce lead times by 35-40%.

Partner with Huaruixin for Your LDI-Enabled FPC/PCB Needs

If you’re developing high-precision FPC, PCB, or rigid-flex board projects that demand the performance benefits of LDI technology, Shenzhen Huaruixin Electronics is your trusted manufacturing partner. Our certified quality system, advanced LDI equipment, and engineering expertise ensure your products meet the most stringent industry standards.

For project inquiries, technical collaboration, or to learn more about LDI technology and our capabilities, visit our website: www.hrxfpc.com or contact us via email: sales@hrxfpc.com. We look forward to exchanging insights and supporting your success in the fast-evolving electronics industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP