Search

Key Materials for High-Performance Flexible Printed Circuit (FPC) Boards

- Apr 23,2025

-

Share

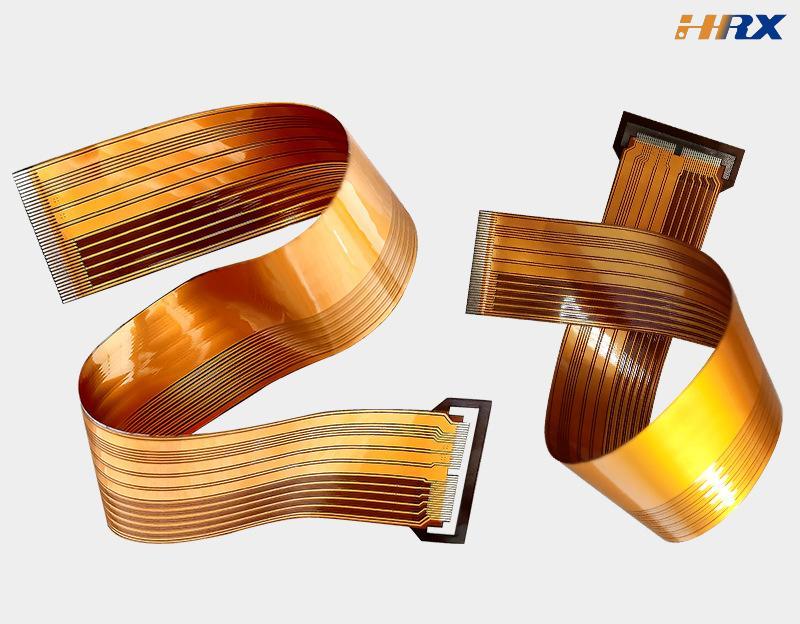

In the rapidly evolving realm of advanced electronics manufacturing, Flexible Printed Circuit (FPC) boards have emerged as a linchpin technology, enabling the miniaturization, flexibility, and high-reliability demands of modern devices. The performance and quality of FPCs are inherently tied to the selection and application of key materials. Shenzhen Huaruixin Electronics Co., Ltd., a leading manufacturer specializing in FPC, PCB, and Rigid-Flex Printed Boards, leverages its deep industry expertise to optimize material choices for superior product outcomes. This blog post delves into the critical materials used in FPC fabrication, incorporating industry - specific jargon and SEO - optimized keywords, while exploring Shenzhen Huaruixin Electronics' strategic material selection and procurement methodologies.

Key Materials for FPCs

1. Substrate Materials

Polyimide (PI): As a high-performance substrate material, polyimide is the preferred choice for high-reliability FPC applications. With exceptional thermal stability (capable of withstanding temperatures up to 260°C and beyond), chemical resistance, and dielectric properties, PI is widely utilized in automotive electronics, aerospace, and high-power device manufacturing. Its superior flex fatigue resistance allows FPCs to endure repeated bending, folding, and flexing cycles without significant degradation, making it an ideal solution for flexible interconnects and rigid-flex designs.

Polyester Film: Cost-effective and versatile, polyester films are commonly employed in consumer electronics applications where moderate temperature resistance and mechanical flexibility suffice. These films offer good dimensional stability and are well-suited for FPCs in smartphones, tablets, and wearable devices, providing a balance between performance and cost.

2. Conductive Layers

Rolled - Annealed (RA) Copper Foil: RA copper foils, produced through a cold-rolling process, exhibit a smooth surface finish and enhanced mechanical properties. The grain alignment achieved during rolling results in superior flexibility and fatigue resistance, making them ideal for high-cycle flex applications, such as flexible displays and connector cables. Their excellent electrical conductivity and adhesion to substrates contribute to the overall reliability of FPCs in demanding environments.

Electrolytic Copper Foil: Manufactured via an electrolysis process, electrolytic copper foils are a more economical option for general-purpose FPCs. While they may have a relatively rougher surface compared to RA foils, advancements in surface treatment technologies have mitigated potential drawbacks, ensuring acceptable electrical performance and adhesion in most applications.

3. Coverlay Materials

Polyester Resin: Polyester resin coverlays are widely used for their cost-efficiency and ease of processing. They provide reliable environmental protection by shielding conductive traces from moisture, dust, and mechanical abrasion, making them suitable for consumer electronics and low to medium-reliability applications.

Polyurethane: Offering exceptional abrasion resistance, chemical resistance, and flexibility, polyurethane coverlays are preferred for high-reliability FPCs in industrial control systems, medical devices, and other applications where the FPC is subjected to harsh operating conditions.

4. Reinforcing Materials

Glass Fiber Cloth: Glass fiber cloth serves as an effective reinforcing material, enhancing the mechanical strength and dimensional stability of FPCs. By preventing excessive stretching and warping, it enables FPCs to support heavier components and withstand mechanical forces, making it a common choice for rigid-flex and high-stress applications.

Polyimide Film: In addition to its role as a substrate, polyimide film can be used as a reinforcing layer to provide high-temperature resistance and additional mechanical strength, ensuring the integrity of FPCs in harsh environments.

5. Auxiliary Materials

Cleaning Liquids: Specialized cleaning solutions are essential for surface preparation, removing contaminants such as grease, dust, and oxides from FPC materials. A clean surface is critical for adhesion promotion and ensuring the quality of subsequent manufacturing processes.

Developing Liquids: In the photolithography process, developing liquids selectively remove the photoresist material, exposing the underlying copper traces. The choice of developer depends on the photoresist type and desired development precision, ensuring accurate pattern transfer.

Etching Liquids: Etchant solutions, such as ferric chloride and ammonium persulfate, are used to selectively remove unwanted copper, forming the desired circuit pattern. Precise control of the etching process is crucial for achieving consistent line widths and high-quality circuit patterns.

Shenzhen Huaruixin Electronics' Strategic Approach to Material Selection and Procurement

1. Rigorous Quality Assurance

Shenzhen Huaruixin Electronics adheres to ISO-certified quality standards in material selection, ensuring that all substrates, copper foils, coverlays, and auxiliary materials meet or exceed industry specifications. For polyimide substrates, the company conducts comprehensive material characterization tests, including thermal gravimetric analysis (TGA), dielectric constant measurement, and tensile strength testing. Similarly, copper foils undergo microscopic surface analysis and electrical conductivity testing to guarantee optimal performance.

2. Application - Specific Material Engineering

Understanding that each application has unique material requirements, Shenzhen Huaruixin Electronics employs an application-driven approach to material selection. For automotive-grade FPCs, which demand AEC-Q100 compliance and high thermal cycling resistance, the company selects premium polyimide substrates and RA copper foils. In contrast, for mass-market consumer electronics, the focus shifts to cost-effective materials without compromising on basic performance metrics.

3. Strategic Supplier Partnerships

The company maintains long-term strategic partnerships with leading material suppliers, ensuring a stable supply chain and access to the latest material innovations. Through joint R&D initiatives and regular supplier audits, Shenzhen Huaruixin Electronics collaborates closely with suppliers to drive continuous improvement in material quality, performance, and sustainability.

4. Cost Optimization and Value Engineering

While upholding high-quality standards, Shenzhen Huaruixin Electronics implements cost optimization strategies through volume purchasing, value analysis/value engineering (VA/VE), and material substitution where appropriate. By leveraging its scale of operations and market insights, the company offers competitive pricing without sacrificing product performance.

5. Research and Development Innovation

Investing heavily in R&D, Shenzhen Huaruixin Electronics explores emerging materials and manufacturing technologies to stay ahead of industry trends. The company's R&D efforts focus on developing next-generation FPC materials with enhanced flexibility, thermal management capabilities, and environmental sustainability, enabling it to meet the evolving demands of the electronics industry.

Conclusion

The selection and procurement of key materials are pivotal in the manufacturing of high-performance FPCs. Shenzhen Huaruixin Electronics Co., Ltd.'s strategic approach to material management, combining technical expertise, quality assurance, and cost optimization, positions it as a trusted partner for FPC, PCB, and Rigid-Flex Printed Board solutions. Whether you are seeking custom FPC designs, high-volume production, or technical consultation, we invite you to visit our website at www.hrxfpc.com or contact us at sales@hrxfpc.com. Let's collaborate to bring your innovative electronics projects to life!

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP