Search

Key Materials Driving FPC Performance: Expert Insights from Huaruixin Electronics

- Jul 09,2025

-

Share

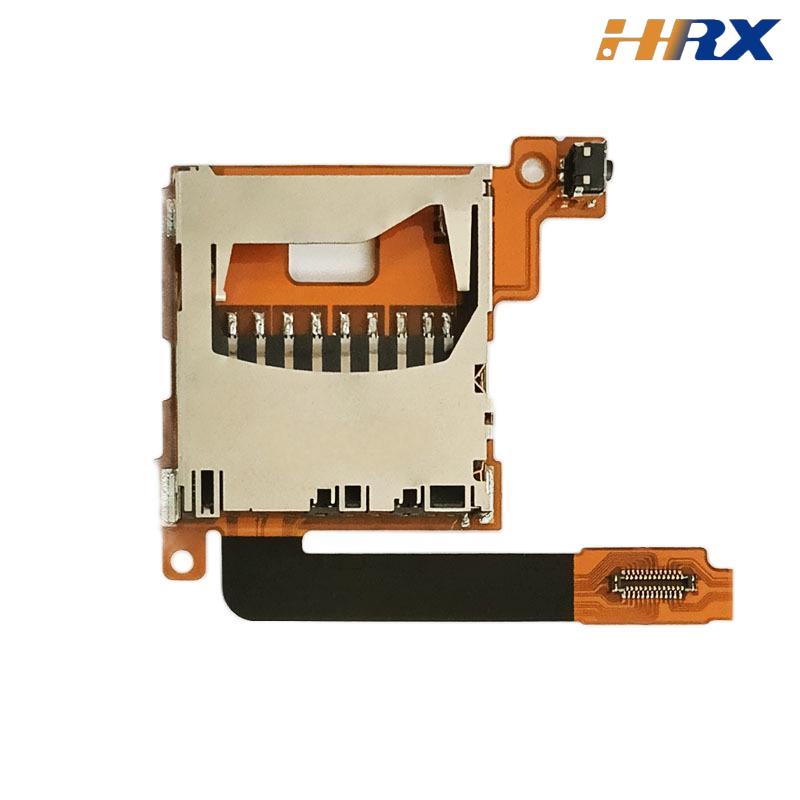

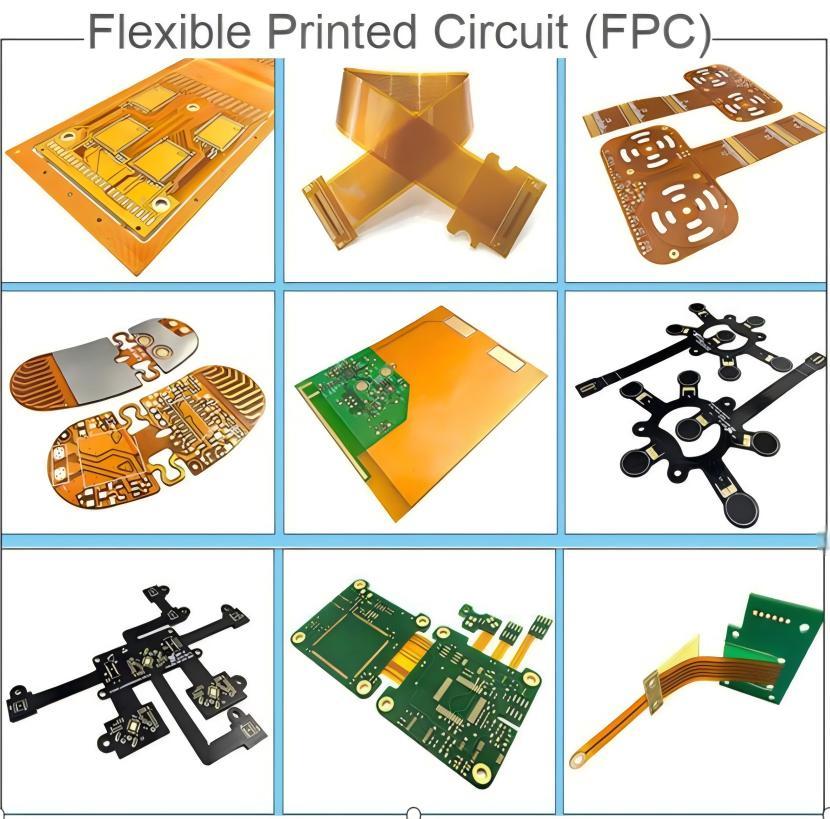

Flexible Printed Circuits (FPC) have become indispensable in modern electronics, enabling miniaturization, design flexibility, and reliable performance in devices ranging from smartphones to medical wearables. Their unique capabilities stem from a precise combination of advanced materials, each playing a critical role in delivering the flexibility, conductivity, and durability that define FPC technology. As a leading FPC&PCB&Rigid-Flex Printed Board ODM/OEM manufacturer, Shenzhen Huaruixin Electronics Co., Ltd. leverages deep material expertise to push the boundaries of FPC innovation.

Core Materials Powering FPC Excellence

Conductive Layers: The Nerve Center of FPCs

Copper foil remains the gold standard for FPC conductive layers, prized for its exceptional electrical conductivity (≥58 MS/m) and formability. Electrolytic copper foil (ECF) and rolled copper foil (RCF) dominate applications: ECF offers cost-effectiveness for standard flex circuits, while RCF provides superior flex endurance—critical for dynamic applications like foldable displays and robotics. Advanced alloys, such as copper-nickel-tin, are emerging for high-frequency FPCs, reducing signal loss in 5G and IoT devices.

Polyimide (PI) Substrates: The Foundation of Flexibility

Polyimide films serve as the primary base material for FPCs, delivering unmatched thermal stability (-269°C to +400°C), chemical resistance, and mechanical resilience. These films, typically 12-125μm thick, enable FPCs to withstand solder reflow temperatures (up to 280°C) while maintaining flexibility. PI’s low dielectric constant (3.0-3.5) minimizes signal delay, making it ideal for high-speed data transmission in aerospace and automotive electronics.

Adhesives: Enabling Layer Integration

Acrylic and epoxy adhesives bond copper layers to PI substrates, balancing adhesion strength (≥1.0 N/cm) with flex fatigue resistance. Adhesive-less FPC constructions, using direct copper lamination (DCL), are gaining traction for ultra-thin designs, eliminating adhesive-related thickness constraints and improving thermal conductivity.

Cover Layers & Solder Masks

Polyimide cover layers protect conductive traces from environmental damage, while photosensitive solder masks (PSM) ensure precise solder joint formation. These materials provide insulation (≥10¹⁴ Ω·cm) and moisture resistance (≤0.1% water absorption), critical for FPC reliability in harsh environments.

Huaruixin Electronics: Advancing FPC Technology Through Material Innovation

At Shenzhen Huaruixin Electronics Co., Ltd., we recognize that material science is the cornerstone of FPC performance. Our R&D team collaborates with material suppliers to optimize formulations for specific applications—whether developing high-temperature FPCs for under-hood automotive use or ultra-flexible circuits for wearable devices. By integrating advanced materials like low-loss PI films and high-purity copper foils, we deliver FPCs with enhanced signal integrity, longer flex life (≥100,000 cycles), and reduced weight.

Our large-scale manufacturing facility is equipped to process these materials with precision, ensuring consistent quality across high-volume production. From prototype to mass production, we leverage material expertise to solve complex design challenges, supporting customers in industries including consumer electronics, medical devices, and industrial automation.

Partner With Huaruixin for Your FPC Needs

If you’re seeking a reliable FPC&PCB&Rigid-Flex manufacturer with deep material and technical expertise, Huaruixin Electronics is your ideal partner. Whether you require custom FPC designs for miniaturized devices or high-reliability circuits for extreme environments, our team is ready to collaborate.

For more insights on FPC materials, design guidelines, or to discuss your project, visit our website at www.hrxfpc.com. You can also email our technical sales team at sales@hrxfpc.com—we’re committed to sharing knowledge and supporting your success in the rapidly evolving FPC landscape.

#FPC #FlexiblePrintedCircuits #PCBMaterials #HuaruixinElectronics #RigidFlexPCBs #FPCTechnology #Electronics Manufacturing

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP