Search

Key Differences Between Rigid-Flex PCBs and Flexible Printed Circuits (FPC)

- Jul 10,2025

-

Share

In the evolving landscape of electronic interconnect solutions, understanding the distinctions between rigid-flex PCBs and flexible printed circuits (FPC) is crucial for engineers, buyers, and manufacturers alike. Both technologies serve critical roles in enabling miniaturization and reliability, but their unique structural and performance attributes make them suited for distinct applications. Below is a detailed breakdown of their core differences, enhanced with industry-specific terminology and insights to guide your next project decision.

1. Structural Composition

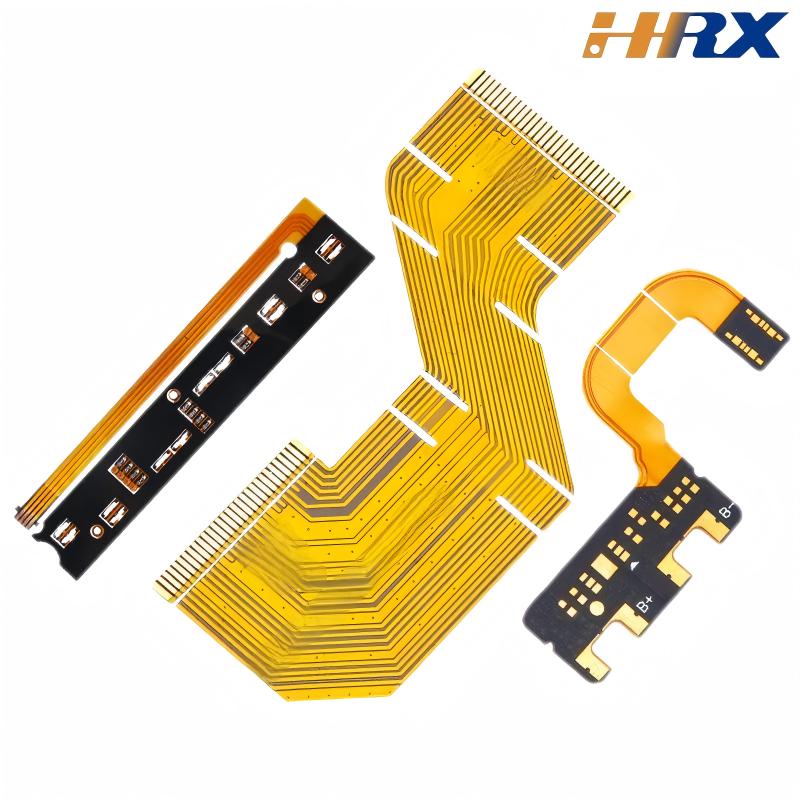

• Flexible Printed Circuits (FPC)

Constructed entirely from flexible substrates such as polyimide (PI) or polyester (PET) films, FPCs feature a homogeneous structure designed for uncompromising flexibility. The core consists of copper clad laminates (CCL) with etched conductive traces, protected by coverlay or solder mask to insulate circuits. Notably, FPCs lack rigid substrates, relying solely on their flexible base materials to achieve bending, folding, and twisting capabilities.

Example applications: LCD display ribbons, wearable device interconnects, and battery flex connectors.

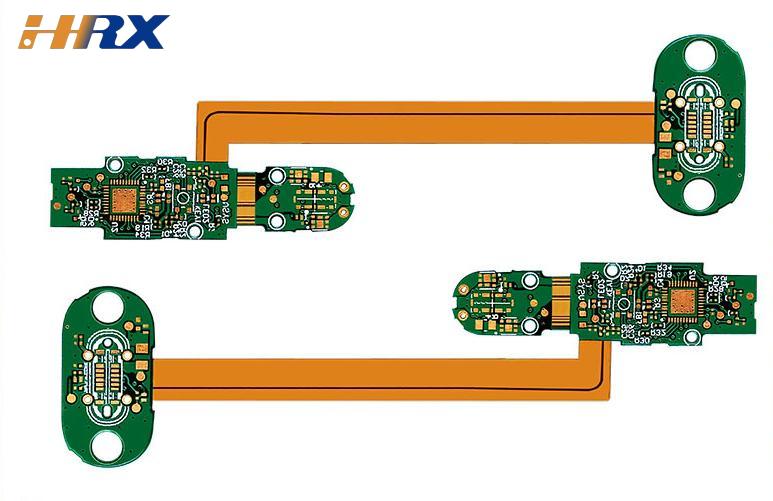

• Rigid-Flex PCBs

Rigid-flex PCBs integrate both flexible segments (typically PI-based) and rigid sections (utilizing FR-4 or high-temperature laminates) into a single, monolithic structure. The flexible regions enable dynamic movement, while rigid areas provide mechanical stability for mounting surface-mount devices (SMDs), connectors, and other components. This hybrid design eliminates the need for separate connectors between rigid and flexible parts.

Example applications: Minimally invasive medical probes, aerospace avionics, and automotive sensor modules.

2. Performance & Functional Attributes

Parameter | Flexible Printed Circuits (FPC) | Rigid-Flex PCBs |

Mechanical Durability | High flexibility but limited tensile strength; requires external reinforcement in harsh environments. | Rigid sections withstand vibration and impact; flexible segments maintain fatigue resistance (up to 100,000+ bending cycles). |

Space Efficiency | Requires additional connectors for integration with rigid PCBs, increasing assembly volume. | Integrates rigid and flexible functions in one unit, reducing overall footprint by 30-50% in compact devices. |

Signal Integrity | Susceptible to noise in long, unsupported runs without shielding. | Optimized for high-frequency performance with controlled impedance and integrated shielding layers. |

Component Integration | Limited to lightweight components; no rigid mounting points. | Supports heavy components (e.g., ICs, sensors) on rigid sections. |

3. Manufacturing Processes

• FPC Production: Involves photolithography for trace etching on flexible substrates, followed by coverlay lamination and electroplating (e.g., gold plating for contact pads). Processes focus on maintaining substrate flexibility throughout.

• Rigid-Flex PCB Production: Adds complex sequential lamination steps to bond rigid and flexible layers, with precise control over dielectric thickness and adhesive properties to prevent delamination. Laser drilling is often used to create microvias between layers, ensuring reliable interconnections.

4. Application-Specific Use Cases

• FPCs excel in applications requiring repetitive bending or low-profile designs:

◦ Consumer electronics (smartphone hinges, tablet battery connectors)

◦ Wearable tech (smartwatch straps, fitness tracker sensors)

◦ LED displays (curved screen interconnects)

• Rigid-Flex PCBs are ideal for high-reliability, space-constrained environments:

◦ Medical devices (implantable electronics, endoscopes)

◦ Automotive systems (ADAS sensors, infotainment modules)

◦ Aerospace & defense (satellite circuitry, UAV components)

Choose the Right Solution with Huaruixin Electronics

Whether your project demands the flexibility of FPCs or the robust integration of rigid-flex PCBs, Shenzhen Huaruixin Electronics Co., Ltd. delivers tailored ODM/OEM solutions. Our expertise spans high-precision FPC manufacturing, complex rigid-flex PCB design, and advanced surface treatments—all optimized for performance and reliability.

For project inquiries or technical guidance, visit www.hrxfpc.com or contact our team at sales@hrxfpc.com. Let’s collaborate to bring your electronic designs to life.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP