Search

Key Considerations in High-Density FPC: Design, Manufacturing, and Quality Control

- Jul 21,2025

-

Share

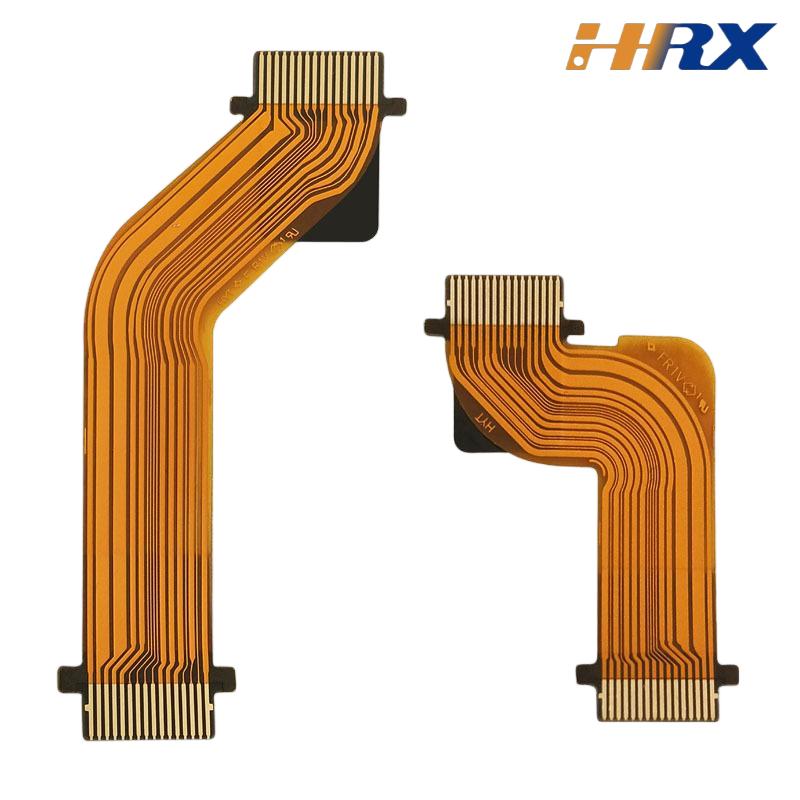

In the fast-evolving electronics industry, high-density flexible printed circuits (High-Density FPCs) have become the backbone of advanced electronic devices, driving innovations in miniaturization, performance enhancement, and design versatility. As electronic products strive for smaller sizes, lighter weights, and higher complexity, the challenges in the design, production, and inspection of high-density FPCs have become more prominent. This blog explores the critical aspects of high-density FPCs and showcases how Shenzhen Huaruixin Electronics Co., Ltd. serves as a reliable partner in overcoming these challenges.

Design Essentials for High-Density FPC

Designing high-density FPCs demands a rigorous approach to guarantee functionality, reliability, and manufacturability. A key factor is trace width and spacing optimization. With the increasing density, traces need to be narrower, and the spacing between them must be reduced, which may cause problems like crosstalk and signal integrity degradation. Advanced CAD tools and signal integrity simulation software are necessary to model and alleviate these risks.

Material selection is also of great significance. High-density FPCs often work in harsh environments, requiring materials with superior thermal stability, chemical resistance, and mechanical flexibility. The choice of substrate (such as polyimide) and coverlay should match the specific application scenarios, whether in automotive electronics, consumer electronics, or medical devices.

Layer stack-up configuration is crucial for the performance of high-density FPCs. Optimizing the number of layers and their arrangement can ensure efficient signal routing, reduce electromagnetic interference (EMI), and maintain structural robustness. Shenzhen Huaruixin Electronics Co., Ltd., with its rich experience in FPC&PCB&Rigid-Flex Printed Board design, excels in providing customized stack-up solutions that balance density and performance.

Manufacturing Precision in High-Density FPC Production

The shift from design to manufacturing in high-density FPC production requires extremely high precision. Photolithography processes must achieve strict tolerances to ensure accurate trace formation. Any deviation can lead to short circuits or open circuits, thus affecting the entire board's functionality.

Etching uniformity is another critical aspect. High-density FPCs need consistent etching to maintain trace integrity, especially for narrow traces. Advanced etching technologies and real-time process monitoring are essential to achieve this level of precision.

Lamination quality has a direct impact on the reliability of high-density FPCs. Ensuring good adhesion between layers, avoiding voids, and maintaining uniform pressure and temperature during lamination are key to preventing delamination and ensuring long-term performance. Shenzhen Huaruixin Electronics Co., Ltd.'s large-scale manufacturing base is equipped with advanced lamination equipment and strict process controls to meet these strict standards.

Quality Inspection in High-Density FPC Manufacturing

Quality inspection for high-density FPCs is more complex due to their intricate designs. Automated Optical Inspection (AOI) systems are essential for detecting tiny defects such as trace breaks, shorts, and misalignments that are invisible to the naked eye.

Electrical testing is equally important. Flying probe testing and in-circuit testing (ICT) are used to verify the electrical performance of high-density FPCs, ensuring that all connections meet the specifications. For high-reliability applications, additional tests like thermal cycling and humidity testing may be required to validate performance under extreme conditions.

Shenzhen Huaruixin Electronics Co., Ltd. integrates comprehensive quality control measures throughout the production process. Leveraging its professional experience as an ODM/OEM manufacturer, the company implements strict inspection protocols to ensure that every high-density FPC meets the highest quality standards.

Why Choose Shenzhen Huaruixin Electronics Co., Ltd.?

Shenzhen Huaruixin Electronics Co., Ltd. stands out as a leading provider of high-density FPCs because of its:

Technical Proficiency: Years of experience in designing and manufacturing FPC&PCB&Rigid-Flex Printed Boards, with in-depth knowledge of high-density FPC requirements.

Advanced Production Facilities: A large-scale manufacturing base equipped with cutting-edge technology to handle the complexities of high-density FPC manufacturing, including precision drilling and plating processes.

Quality Assurance: Strict quality control procedures that ensure the reliability and performance of each product.

Customer - Oriented Service: ODM/OEM capabilities to meet custom needs, supported by responsive customer service.

If you have a project requiring high-density FPCs, Shenzhen Huaruixin Electronics Co., Ltd. is ready to help. For more industry knowledge, you can visit our website: www.hrxfpc.com or email us at sales@hrxfpc.com to consult, communicate, learn, and get guidance together. Let's work together to make your electronic designs a reality.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP