Search

Key Considerations in 5G FPC Design, Production, and Inspection: Insights from Shenzhen Huaruixin Electronics

- Jul 19,2025

-

Share

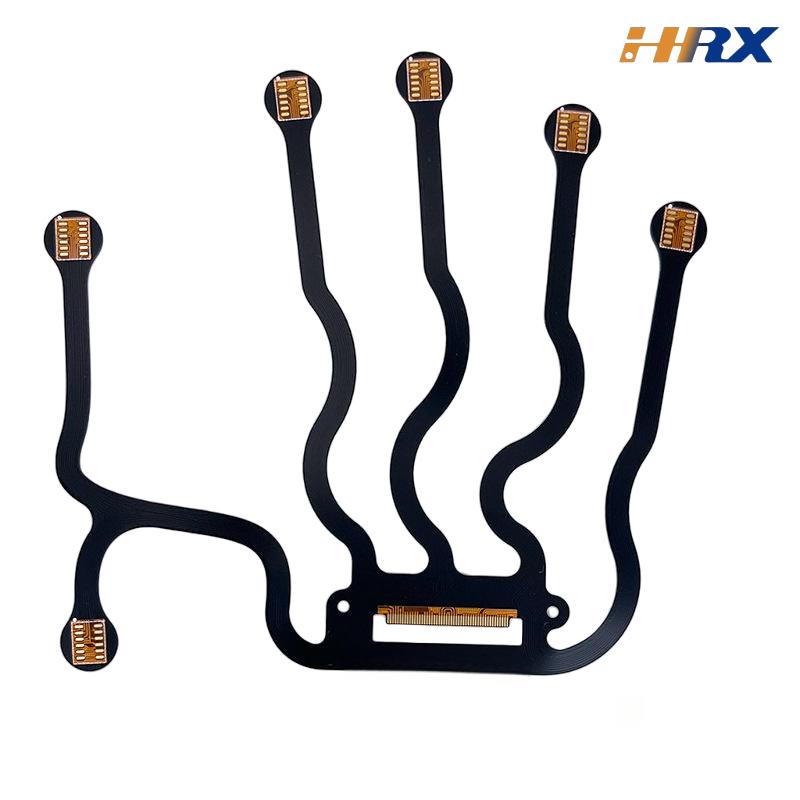

In the fast - evolving realm of 5G technology, Flexible Printed Circuits (FPC) stand as a cornerstone, empowering the development of high - speed, reliable, and miniaturized electronic devices. 5G FPC, boasting unique flexibility and superior performance, has become an indispensable component in a wide range of 5G - driven products. Yet, the design, manufacturing, and quality inspection of 5G FPC present a series of critical challenges that call for specialized knowledge and profound expertise. In this blog, we will explore these key issues in depth and see how Shenzhen Huaruixin Electronics Co., Ltd., a professional ODM/OEM manufacturer specializing in FPC, PCB, and Rigid - Flex Printed Boards, with rich experience and a large - scale production base, tackles them.

Key Issues in 5G FPC Design

The design stage of 5G FPC is crucial for its overall performance. Signal integrity is a top priority. 5G communication operates at high frequencies, making the FPC susceptible to signal attenuation, crosstalk, and electromagnetic interference (EMI). To address these problems, meticulous planning of the circuit trace layout is essential. The length, width, and spacing of the traces must be accurately calculated to guarantee optimal signal transmission.

Material selection is another vital factor in 5G FPC design. The flexible circuit substrates and conductive materials need to have excellent high - frequency electrical properties, such as low dielectric constant (Dk) and low dissipation factor (Df). Materials like liquid crystal polymer (LCP) and modified polyphenylene oxide (MPPO) are frequently chosen for 5G FPC due to their outstanding performance at high frequencies.

Flexural endurance and mechanical robustness are also important design considerations. 5G devices often undergo frequent bending and twisting, so the FPC must be designed to withstand these mechanical stresses without losing functionality. This involves selecting appropriate thicknesses for the substrate and conductive layers, as well as optimizing the design of the bend radius and flex zones.

Shenzhen Huaruixin Electronics Co., Ltd. excels in 5G FPC design. With a team of professional designers and developers, they utilize advanced EDA (Electronic Design Automation) software and signal integrity simulation tools to ensure that the FPC meets the strict signal integrity and mechanical requirements of 5G applications. Their extensive industry experience allows them to predict potential design issues and offer innovative 5G FPC solutions.

Critical Factors in 5G FPC Production

The manufacturing process of 5G FPC requires high precision and strict quality control. Process accuracy is of utmost significance. The fabrication of fine - pitch circuits, which is necessary for 5G FPC to accommodate the high component density, demands advanced manufacturing equipment and cutting - edge techniques. Even a tiny deviation in the production process can result in short circuits or open circuits, affecting the performance of the FPC.

Environmental control during production is also critical. Factors such as temperature, humidity, and particulate matter levels can impact the quality of the FPC. Shenzhen Huaruixin Electronics Co., Ltd. has a large - scale manufacturing base equipped with state - of - the - art cleanroom facilities and environmental control systems to ensure stable production conditions. This helps maintain the consistency and reliability of 5G FPC.

Another key production aspect is the selection of suitable manufacturing processes. Processes like photolithography, etching, plating, and lamination must be optimized to achieve the desired electrical and mechanical properties of the FPC. The company's expertise in ODM/OEM production enables it to customize manufacturing processes to meet the specific requirements of each 5G FPC project.

Essential Aspects of 5G FPC Inspection

Strict inspection is vital to ensure the quality of 5G FPC. Comprehensive electrical testing is essential, including tests for continuity, insulation resistance, and high - frequency insertion loss. Advanced testing equipment such as vector network analyzers (VNA) and oscilloscopes are used to accurately measure these parameters.

Mechanical testing is also necessary to verify the flexural strength and durability of the FPC. Tests such as dynamic bending tests, torsion tests, and thermal shock tests are conducted to ensure that the FPC can withstand the harsh operating conditions of 5G devices.

Visual inspection is another important part of the quality control process. It involves checking for defects such as cracks, delamination, and uneven plating. Automated optical inspection (AOI) systems and X - ray inspection machines are used to detect these defects with high precision and efficiency.

Shenzhen Huaruixin Electronics Co., Ltd. implements a strict and comprehensive inspection process for 5G FPC. Their quality control team uses advanced testing equipment and follows strict inspection procedures to ensure that every FPC meets the highest quality standards. This commitment to quality has made them a trusted 5G FPC manufacturer in the industry.

Conclusion

The design, production, and inspection of 5G FPC are complex processes that require a deep understanding of 5G technology and specialized manufacturing expertise. Shenzhen Huaruixin Electronics Co., Ltd., with its professional design and development capabilities, large - scale manufacturing base, and extensive industry experience, is well - equipped to address the critical issues in 5G FPC production.

If you have a 5G FPC project requirement, we, as a professional manufacturer, welcome you to contact us at any time. For more industry knowledge, you can visit our website: www.hrxfpc.com or email us at sales@hrxfpc.com to consult, exchange ideas, learn from each other, and get guidance. Let's work together to drive the progress of 5G technology with high - quality FPC solutions.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP