Search

Key Considerations for Rigid-Flex Printed Board Quality Control

- May 26,2025

-

Share

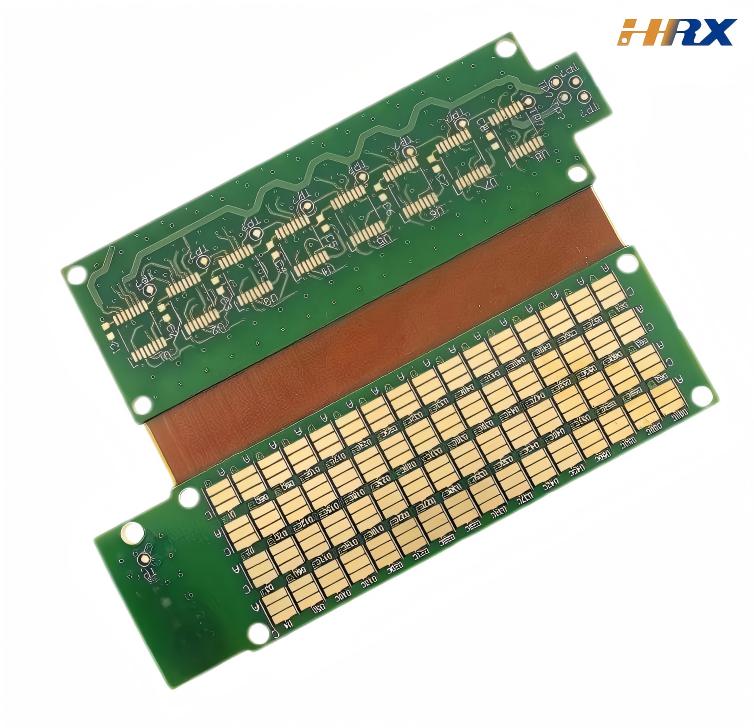

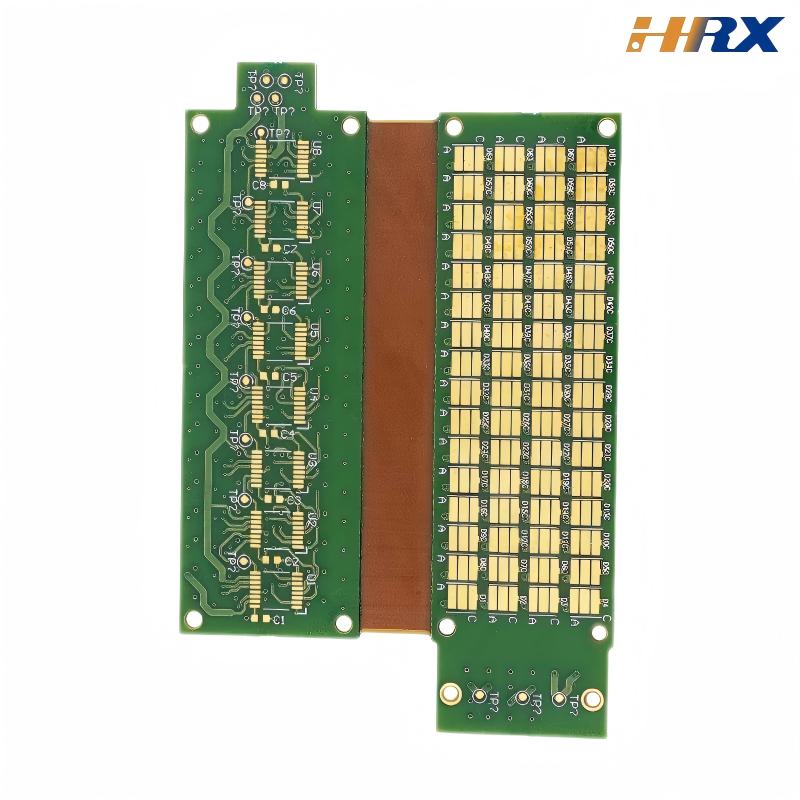

In the rapidly advancing realm of electronics manufacturing, Rigid-Flex Printed Boards (RFPCs) have become indispensable components, seamlessly integrating flexibility and rigidity to fulfill the intricate requirements of contemporary devices. As a leading global manufacturer specializing in Flexible Printed Circuit (FPC), Printed Circuit Board (PCB), and Rigid-Flex PCB Assembly, Shenzhen Huaruixin Electronics Co., Ltd. understands that stringent quality control is the cornerstone of producing high-reliability, high-performance rigid-flex boards.

Design Phase: Laying the Groundwork for Superior Quality

The design stage serves as the bedrock for the success of any rigid-flex board. A meticulously crafted design not only mitigates numerous production challenges but also guarantees optimal functionality in the intended application. Layer stack-up design is a pivotal aspect that warrants careful consideration. Incorrect layer sequencing or inappropriate material selection can give rise to a plethora of issues, including subpar electrical performance, mechanical instability, and even delamination. From our extensive experience, seamless collaboration between design and engineering teams is non-negotiable. For example, when engineering a rigid-flex board for a state-of-the-art wearable device, we meticulously analyzed the bend radius requirements to ensure the board could endure repeated flexing without compromising its integrity. By capitalizing on our in-house design prowess and utilizing advanced design software, we were able to create a customized layer stack-up that met both the exacting electrical and mechanical specifications, thereby enhancing the overall reliability of the final product.

Signal integrity is another linchpin in rigid-flex board design, especially in the era of high-speed data transmission. Ensuring accurate and interference-free signal propagation is of utmost importance. Advanced routing techniques, such as differential pair routing, controlled impedance routing, and impedance matching, play a crucial role in maintaining signal integrity. At Shenzhen Huaruixin Electronics, our design engineers employ cutting-edge CAD tools and simulation software to conduct in-depth signal integrity analysis and optimize the routing layout. This proactive approach enables us to identify potential signal integrity issues at the design phase, facilitating timely adjustments to ensure the highest quality of the end product.

Material Selection: Selecting the Optimal Building Blocks

The quality of a rigid-flex board is intrinsically linked to the materials employed. Different applications necessitate materials with specific properties, and a suboptimal material choice can significantly impinge on the board's performance and longevity. In the realm of flexible materials, polyimide stands out as a preferred choice due to its exceptional mechanical and electrical properties, as well as its remarkable resistance to high temperatures. However, the selection of adhesives, coverlay materials, and dielectric substrates also demands scrupulous evaluation. Inferior-quality adhesives may fail to form a robust bond between layers, potentially leading to delamination over time.

Based on our years of experience in the industry, we have established a stringent material procurement process. We source materials exclusively from reputable suppliers renowned for their quality and reliability. Rigorous incoming material inspection protocols are in place, encompassing a battery of tests, including peel strength testing for adhesives, tensile strength testing for flexible substrates, and dielectric constant measurement for dielectric materials. By maintaining a robust supply chain and implementing comprehensive quality control measures for materials, we can assure our customers that our rigid-flex boards are engineered to deliver consistent performance across a wide range of operating conditions.

Manufacturing Process: Precision Engineering at Every Stage

The manufacturing process of rigid-flex boards is a complex and intricate operation that involves multiple sequential steps, each requiring precise control to uphold the highest quality standards. Lamination, a critical process in rigid-flex board fabrication, demands meticulous monitoring and control of temperature, pressure, and time parameters. Any deviation from the specified lamination parameters can result in defects such as voids, delamination, or uneven layer thickness.

Our large-scale manufacturing facility is outfitted with state-of-the-art lamination equipment featuring advanced temperature and pressure control systems. In addition, we have implemented strict process control procedures, including regular equipment calibration, real-time process monitoring, and statistical process control (SPC). These measures ensure consistent and repeatable lamination results, guaranteeing that every rigid-flex board we produce adheres to the most exacting quality standards.

Drilling and routing are other crucial manufacturing processes that require precision and accuracy. Precise hole positioning and accurate routing are essential for proper component placement and electrical connectivity. We utilize high-precision CNC drilling and routing machines equipped with advanced vision systems to ensure that holes are drilled to the precise size and location, and the board is routed cleanly without any burrs or rough edges. Our highly skilled operators adhere to strict quality control protocols during these processes, minimizing the occurrence of defects and ensuring the overall quality and reliability of the finished product.

Testing and Inspection: Upholding Quality Excellence

Testing and inspection are the final safeguards in ensuring the quality and reliability of rigid-flex boards. A comprehensive testing regime should encompass electrical testing, mechanical testing, and visual inspection. Electrical tests, such as continuity testing, insulation resistance testing, and impedance testing, are conducted to verify the board's electrical performance and compliance with the specified electrical requirements. Mechanical tests, including bend testing, peel strength testing, and thermal shock testing, assess the board's mechanical durability and the integrity of the bonds between layers.

At Shenzhen Huaruixin Electronics, we have made substantial investments in advanced testing equipment, including automated optical inspection (AOI) systems, flying probe testers, and environmental test chambers. Our team of experienced quality control technicians is trained to perform rigorous testing and inspection procedures, ensuring that every rigid-flex board undergoes 100% electrical testing and comprehensive visual inspection. Any visible defects, such as scratches, cracks, solder bridges, or component placement errors, are meticulously identified and rectified before the boards are shipped to our customers. By implementing a comprehensive quality control system, we can provide our customers with high-quality, reliable rigid-flex boards that meet or exceed their expectations.

In conclusion, ensuring the quality of rigid-flex printed boards demands a holistic approach that encompasses every aspect of the product lifecycle, from design and material selection to manufacturing, testing, and inspection. As a trusted provider of FPC, PCB, and Rigid-Flex PCB solutions, Shenzhen Huaruixin Electronics Co., Ltd. is dedicated to delivering cost-effective, high-quality products that meet the diverse needs of our global customers. If you are in search of reliable rigid-flex board solutions, we invite you to visit our website at www.hrxfpc.com to learn more about our products and services or contact us via email at sales@hrxfpc.com. We look forward to the opportunity to collaborate with you, share our industry insights, and contribute to the success of your projects.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP