Search

Key Considerations for Designing Rigid-Flex Printed Boards in Communication Equipment

- May 19,2025

-

Share

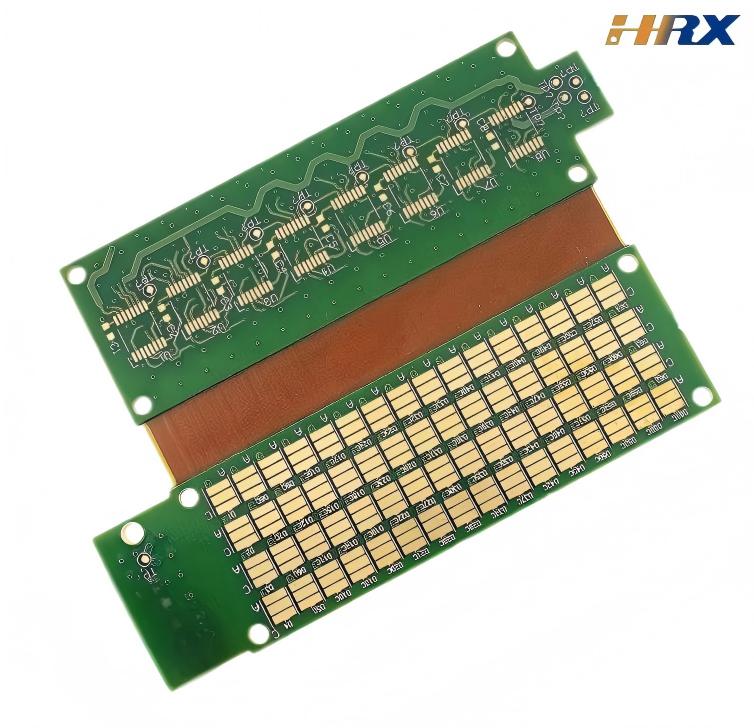

In the rapidly evolving realm of modern communication technology, Rigid-Flex Printed Boards (RFPCs) have become an indispensable component, especially in high-performance communication devices. As a leading global ODM/OEM manufacturer specializing in Flexible Printed Circuits (FPCs), Printed Circuit Boards (PCBs), and Rigid-Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. possesses in-depth expertise in the pre-design phase of RFPCs tailored for communication equipment. Here are the pivotal factors that demand meticulous consideration.

Signal Integrity and High-Frequency Performance

Signal integrity stands as a cornerstone in the design of RFPCs for communication systems. In cutting-edge applications like 5G base stations and high-speed data centers, where data transfer rates soar into the gigabit range, maintaining pristine signal quality is non-negotiable. Any degradation in signal can lead to data loss, reduced throughput, and system failures.

At Shenzhen Huaruixin Electronics, we employ advanced design methodologies centered around high-frequency impedance control. Our engineers meticulously calculate and optimize the characteristic impedance of transmission lines, leveraging techniques such as controlled impedance routing and differential signaling. With our state-of-the-art manufacturing facilities equipped with precision impedance measurement tools, we ensure an impedance tolerance of ±5%, crucial for minimizing signal reflections and crosstalk in high-speed differential pairs, which are prevalent in 5G millimeter-wave communication links.

Moreover, electromagnetic interference (EMI) mitigation is a top priority. We integrate shielding structures, including copper shielding layers and ground planes, into the FPC and RFPC designs. These shielding measures, combined with proper grounding strategies, effectively isolate sensitive signal paths from external electromagnetic noise, ensuring compliance with stringent EMC standards like FCC Part 15 and EN 55032.

Flexibility and Durability in Harsh Environments

Communication equipment often operates in diverse and challenging environments, demanding RFPCs that offer both flexibility and durability. The ability to route circuits in three dimensions through flexible layers enables compact designs, but it must be balanced with robust mechanical performance.

Our company has developed proprietary manufacturing processes for FPCs and RFPCs to enhance their flexibility and durability. We utilize high-quality polyimide-based flexible dielectrics renowned for their exceptional bending fatigue resistance. Rigorous in-house testing reveals that our materials can endure over 100,000 bending cycles at a radius of 5mm without significant degradation in electrical performance.

The critical junctures between rigid and flexible sections are engineered with precision. Our patented adhesive bonding techniques and reinforced transition zones ensure a reliable connection, minimizing the risk of delamination and mechanical failure. This is particularly vital for outdoor communication equipment, such as remote radio heads (RRHs), which are exposed to vibrations, temperature fluctuations, and mechanical stress.

Thermal Management for High-Power Applications

With the increasing power density of communication devices, effective thermal management has become a make-or-break factor. Excessive heat can cause component derating, reduced lifespan, and even catastrophic failures. In RFPC design, thermal considerations are integral from the very beginning.

We incorporate advanced thermal management strategies, starting with thermal vias. These vias, strategically placed beneath high-power components like power amplifiers and FPGA chips, efficiently transfer heat from the flexible layers to the rigid sections, which can then dissipate heat through external heat sinks. Our manufacturing capabilities allow for the production of micro-vias with diameters as small as 50μm, enabling high-density thermal transfer.

In addition, we utilize thermally conductive adhesives and dielectric materials with high thermal conductivity in FPC and RFPC construction. These materials enhance heat dissipation within the flexible layers, preventing hotspot formation and ensuring uniform temperature distribution across the board. By conducting comprehensive thermal simulations during the design phase, we optimize the layout to achieve optimal thermal performance.

Miniaturization and High-Density Integration

The relentless drive towards miniaturization in communication equipment necessitates RFPCs with unparalleled high-density integration capabilities. At Shenzhen Huaruixin Electronics, we stay at the forefront of technological advancements to meet these demands.

Our manufacturing prowess extends to producing FPCs and RFPCs with ultra-fine line/space geometries. Using advanced photolithography and electroplating processes, we can achieve line widths and spaces as small as 25μm, enabling the integration of more components in a compact footprint. We also embrace advanced packaging technologies like chip-on-flex (COF) and system-in-package (SiP) integration on RFPCs, further reducing the overall size while increasing functionality.

Our large-scale manufacturing base, equipped with automated SMT lines and precision assembly equipment, ensures high-quality production with tight tolerances. This combination of technological expertise and manufacturing scale allows us to deliver RFPC solutions that are not only highly reliable but also cost-effective for mass production in the communication industry.

If you are seeking professional design and manufacturing services for Rigid-Flex Printed Boards tailored to communication equipment, Shenzhen Huaruixin Electronics Co., Ltd. is your ideal partner. New and old friends are welcome to reach out to us. Visit our website www.hrxfpc.com to explore more about our products and services, or send an email to sales@hrxfpc.com for detailed consultations. Let’s collaborate, exchange ideas, and jointly drive innovation in the communication technology field.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP