Search

Key Considerations for Designing and Manufacturing FPC Circuit Boards for Graphics Tablets

- Feb 19,2025

-

Share

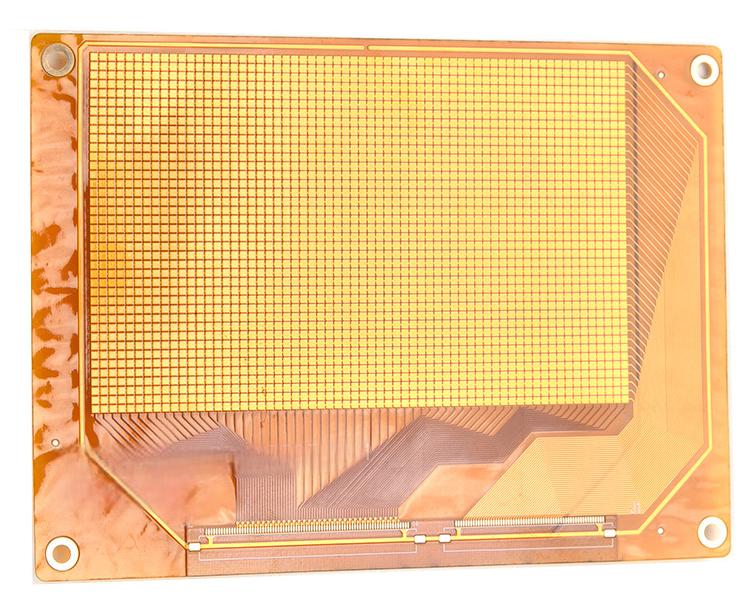

In the realm of contemporary digital input devices, graphics tablets are of utmost significance, particularly for professionals in graphic design, digital art, and certain engineering and architectural fields. The Flexible Printed Circuit (FPC) board within a graphics tablet serves as a linchpin component. It undertakes the critical task of precisely transmitting signals and guaranteeing the seamless operation of the device. Designing and manufacturing FPC circuit boards for graphics tablets demands meticulous attention to multiple facets to satisfy the high - performance requisites of these devices.

1. Design - related Considerations

1.1 Signal Integrity

Graphics tablets hinge on the accurate transmission of signals between the pen and the tablet surface. During the design phase of the FPC circuit board, signal integrity must be accorded the highest priority. High - speed signals necessitate meticulous routing to avert issues such as signal attenuation, reflection, and crosstalk. For instance, the tracks for pen - position detection signals ought to be isolated from other high - frequency signals. Employing proper impedance - matching techniques, like regulating the impedance of the traces to a specific value (e.g., 50 ohms or 75 ohms contingent on the system requirements), can substantially enhance signal integrity.

1.2 Mechanical Design Compatibility

Given that FPC boards are flexible, they must be designed to endure the mechanical stress encountered during the normal usage of the graphics tablet. The bending radius of the FPC needs to be meticulously calculated. An overly small bending radius can give rise to cracks in the conductive traces over time, resulting in circuit malfunctions. Moreover, the attachment points of the FPC to other components within the tablet, such as the main control board and the touch - sensitive surface, must be designed to ensure a secure connection while permitting the requisite flexibility.

1.3 Thermal Management

During operation, the components on the FPC board may generate heat. Despite the relatively low power consumption of a graphics tablet, effective thermal management remains essential to ensure the long - term stability of the FPC. Utilizing materials with excellent thermal conductivity for the FPC substrate and devising proper heat - dissipating areas can aid in efficient heat dissipation. This is particularly crucial when the FPC is in close proximity to heat - generating components like the tablet's controller.

2. Ensuring Reliability and Stability in Graphics Tablets

2.1 Reliability in Interconnects

The reliability of FPC in a graphics tablet highly depends on the integrity of its interconnects. Anisotropic Conductive Films (ACFs) are often used for connecting the FPC to other components. These films contain conductive particles that enable electrical connection when pressure is applied during the bonding process. Precise control of the bonding temperature, pressure, and time is crucial. If the bonding parameters are not optimized, it can lead to poor electrical connections, which may cause intermittent failures in the tablet's operation. For example, improper bonding can result in the pen not registering on the tablet surface accurately or erratic cursor movement.

2.2 Stability in Flex Cycling

Graphics tablets are often used in a way that subjects the FPC to repeated flexing. To ensure stability, the FPC must be designed to withstand a high number of flex cycles. This involves using high - quality flexible materials and appropriate design features such as rounded corners on the FPC to reduce stress concentrations. Manufacturers often conduct accelerated life tests, such as flex - fatigue testing, to simulate real - world usage conditions. By subjecting the FPC to a large number of flex cycles in a controlled environment, they can predict its long - term stability and reliability.

3. Manufacturing - related Considerations

3.1 Material Selection

The choice of materials for FPC manufacturing is of critical importance. The base material of the FPC, typically a polyimide film, should possess excellent flexibility, high - temperature resistance, and electrical insulation properties. The conductive material, such as copper foil, needs to have high purity to ensure optimal electrical conductivity. Additionally, the adhesives employed in the multi - layer FPC manufacturing process should have robust adhesion and be capable of withstanding diverse environmental conditions.

3.2 Manufacturing Process Precision

The manufacturing process of FPC for graphics tablets demands a high degree of precision. The line width and line spacing of the conductive traces must be precisely controlled. In a high - resolution graphics tablet, for example, the line width may need to be as minuscule as 50 - 100 microns. Precise etching and plating processes are indispensable to ensure the quality of the FPC. Any deviation in the manufacturing process can culminate in short - circuits, open - circuits, or inconsistent signal transmission.

3.3 Quality Control

Rigorous quality control measures are imperative during the manufacturing of FPC for graphics tablets. This encompasses visual inspection for any visible defects like scratches, voids, or misalignment of layers. Electrical testing, such as continuity testing and impedance testing, should be carried out on each FPC board to ensure it adheres to the design specifications. Furthermore, environmental testing, such as temperature - humidity cycling and vibration testing, can assist in evaluating the long - term reliability of the FPC.

4. Conclusion

Designing and manufacturing FPC circuit boards for graphics tablets is a multifaceted task that demands a profound understanding of both design and manufacturing tenets. Shenzhen Huaruixin Electronics Co., Ltd. is a preeminent FPC manufacturer with extensive experience and state - of - the - art technology in this domain. Our team has in - depth knowledge of the considerations elaborated above and has successfully designed and produced high - quality FPC circuit boards for diverse applications, including graphics tablets. We cordially welcome new and old friends to engage in communication, discussion, and collaborative learning, with the aim of continuously elevating the performance and quality of FPC products in the industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP