Search

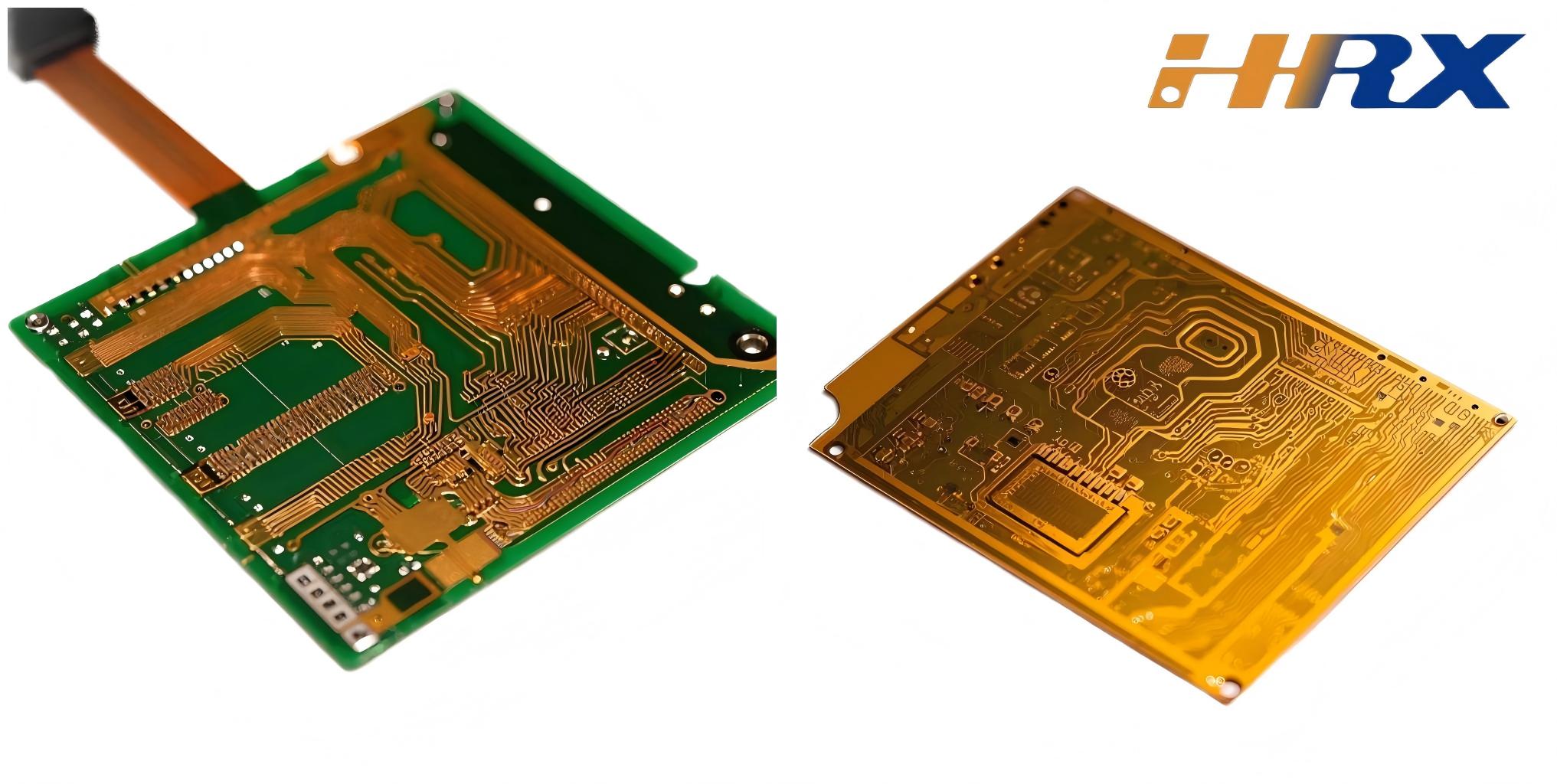

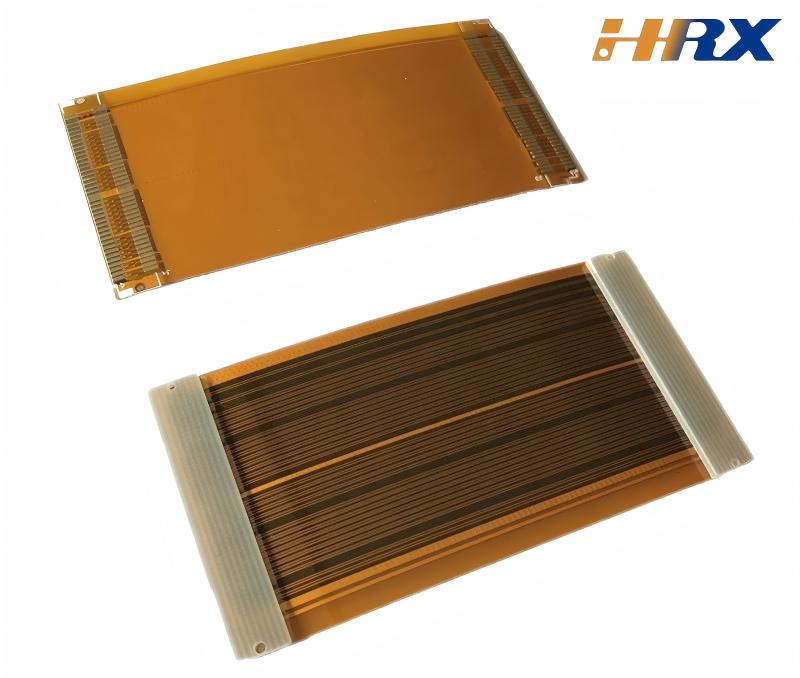

How to Select Suitable Materials for FPC Production

- May 24,2025

-

Share

Choosing the right materials for Flexible Printed Circuits (FPCs) is critical to ensuring performance, reliability, and cost-effectiveness across diverse applications—from consumer electronics to aerospace and medical devices. The selection process involves balancing mechanical, electrical, thermal, and environmental requirements while considering manufacturability and industry standards. Below is a detailed guide to material selection for FPCs, incorporating insights from Shenzhen Huaruixin Electronics Co., Ltd., a global leader in high-precision FPC, PCB, and rigid-flex manufacturing.

1. Base Substrate Materials

The base substrate forms the structural foundation of an FPC, influencing flexibility, thermal stability, and chemical resistance. Key options include:

a. Polyimide (PI)

Properties: High thermal stability (operating temperature: -100°C to +280°C), excellent chemical resistance, and mechanical durability. PI is ideal for dynamic flex applications requiring frequent bending (e.g., foldable displays, robotics).

Applications: Aerospace, automotive, medical devices, and high-temperature environments.

Considerations: More expensive than PET but offers superior performance in harsh conditions. Thicknesses typically range from 12.5μm to 125μm.

b. Polyester (PET)

Properties: Lower cost, moderate flexibility, and good electrical insulation, but limited thermal resistance (max ~130°C). Suitable for static or low-flex applications.

Applications: Consumer electronics (e.g., keyboards, sensors), low-power devices, and short-term use cases.

Considerations: Prone to moisture absorption and degradation at high temperatures. Common thicknesses: 25μm to 100μm.

c. Liquid Crystal Polymer (LCP)

Properties: Ultra-high thermal stability (+300°C+), low moisture absorption, and excellent dimensional stability. Ideal for extreme environments.

Applications: Industrial equipment, military, and aerospace components.

Considerations: Higher cost and less flexibility than PI; used in niche high-reliability applications.

Shenzhen Huaruixin’s Insight: We prioritize PI for most high-reliability FPCs, leveraging its balance of flexibility and thermal performance. For cost-sensitive projects, we offer PET-based solutions with enhanced surface treatments to improve durability.

2. Conductive Materials

The choice of conductive layers directly impacts electrical performance and signal integrity.

a. Copper (Cu)

Types:

Electrolytic Copper (ED): Thicker (18–35μm), cost-effective, but with a rough surface that may affect signal integrity in high-frequency applications.

Rolled Annealed Copper (RA): Thinner (9–18μm), smoother surface, and better flexibility for fine-pitch traces and dynamic flex.

Applications: ED copper for power traces; RA copper for high-speed signals (e.g., USB 4, HDMI) and flexible zones.

Plating: Surface finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) enhance solderability and corrosion resistance.

b. Aluminum or Stainless Steel (for Stiffeners)

Purpose: Reinforce rigid areas of rigid-flex PCBs or provide EMI shielding. Stainless steel offers better heat dissipation, while aluminum is lighter.

Thickness: Typically 50–200μm, depending on mechanical requirements.

Shenzhen Huaruixin’s Insight: We use RA copper for fine-line FPCs (line widths as small as 50μm) to minimize signal loss. Our ENIG plating ensures consistent solder joint reliability in automated assembly processes.

3. Dielectrics and Adhesives

These materials bond layers and provide electrical insulation, affecting flexibility and thermal management.

a. Dielectric Films

Polyimide Dielectrics: Match the base substrate for thermal expansion compatibility. Thicknesses: 12.5–50μm.

Non-Adhesive Dielectrics: Thin, adhesive-free films (e.g., 3M™ Kapton®) reduce overall thickness and improve flexibility in multi-layer FPCs.

Thermally Conductive Dielectrics: Filled with ceramics (e.g., aluminum oxide) to dissipate heat in power-intensive designs.

b. Adhesives

Thermoplastic vs. Thermoset:

Thermoplastic Adhesives (e.g., acrylic): Reusable, flexible, but lower thermal resistance (max ~150°C).

Thermoset Adhesives (e.g., epoxy, polyimide): Permanent bond, higher thermal stability (up to 250°C), but less forgiving during rework.

Thickness: 12–50μm; thinner adhesives reduce stress concentration in flex zones.

Shenzhen Huaruixin’s Insight: For rigid-flex boards, we use non-adhesive PI dielectrics to minimize stack-up thickness and improve bend performance. Our automated lamination processes ensure uniform adhesive distribution and void-free bonds.

4. Cover Layers and Protective Coatings

Protective layers shield conductive traces and enhance mechanical durability.

a. Coverlays

Polyimide Coverlays: Flexible, heat-resistant, and ideal for dynamic flex areas. Thickness: 12.5–25μm.

Solder Masks: Liquid-applied coatings (e.g., epoxy-based) for static flex or rigid regions, offering precise via definition and lower cost.

Adhesive-Backed vs. Non-Adhesive: Adhesive-backed coverlays simplify bonding but add thickness; non-adhesive types (e.g., dry film) are thinner for high-density designs.

b. Surface Coatings

Silicone Coatings: Provide water resistance and mechanical cushioning for wearable devices or medical applications.

Parylene Coating: Ultra-thin (1–5μm), conformal coating for hermetic sealing in harsh environments (e.g., underwater or high-humidity conditions).

Shenzhen Huaruixin’s Insight: We recommend polyimide coverlays for FPCs requiring >10,000 bend cycles, as they outperform solder masks in fatigue resistance. For medical devices, our parylene coating services meet ISO 10993 biocompatibility standards.

5. Key Considerations for Material Selection

a. Application Requirements

Environment: High temperature (PI/LCP), moisture (parylene coating), or chemicals (fluoropolymer dielectrics).

Mechanical Stress: Dynamic flex (RA copper + non-adhesive dielectrics) vs. static flex (ED copper + adhesive-based layers).

Electrical Performance: High-frequency signals (controlled impedance, smooth RA copper), low power (PET substrates).

b. Cost vs. Performance

Balance premium materials (e.g., PI, RA copper) with budget constraints. For example, use PET for prototypes or low-volume static flex applications.

Optimize layer counts and material thicknesses to reduce costs without compromising reliability.

c. Regulatory Compliance

Ensure materials meet RoHS, REACH, UL, or industry-specific standards (e.g., IPC-4202 for flexible dielectrics).

For medical/aerospace applications, prioritize biocompatible (ISO 10993) or flame-retardant (UL 94 V-0) materials.

Shenzhen Huaruixin’s Insight: Our material library includes RoHS-compliant PI, RA copper, and ENIG plating, with full traceability for aerospace and automotive projects. We collaborate with suppliers like DuPont and 3M to source certified materials.

6. Partnering with an Expert Manufacturer

Shenzhen Huaruixin Electronics streamlines material selection through:

Application-Specific Consultation: Our engineers analyze your design requirements to recommend optimal materials (e.g., LCP for aerospace, PI for automotive).

Material Testing: In-house validation of bend fatigue, thermal cycling, and chemical resistance to ensure performance.

Supply Chain Integration: Direct partnerships with material suppliers ensure consistent quality and lead time reliability.

For custom FPC solutions, contact us at sales@hrxfpc.com or visit www.hrxfpc.com. Our expertise in material science and advanced manufacturing ensures your FPCs deliver unmatched performance and longevity.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP