Search

How to reduce FPC impedance drift in high-humidity environments?

- Oct 11,2025

-

Share

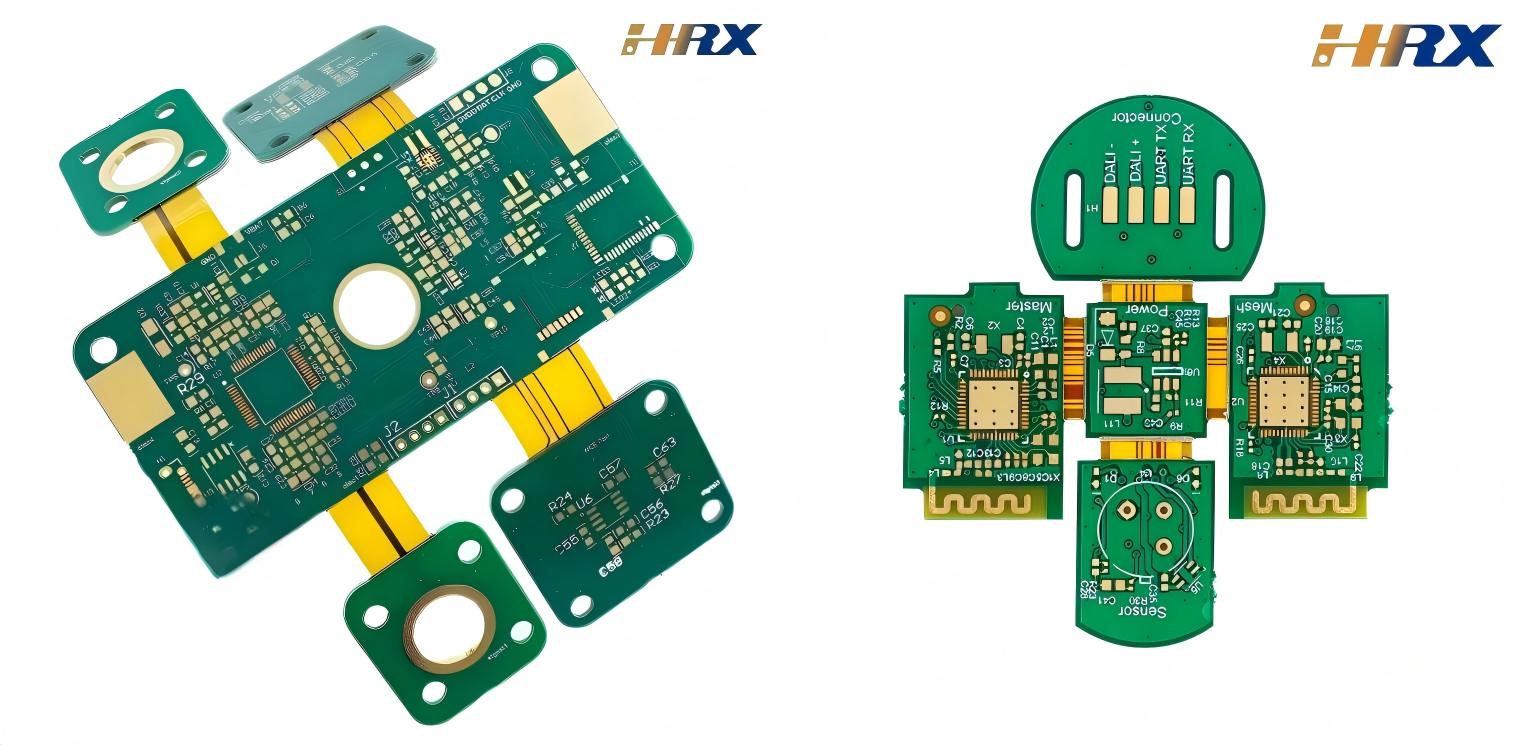

To address the challenge of FPC impedance drift in high-humidity environments, Shenzhen Huaruixin Electronics Co., Ltd.’s professional practices as a leading FPC/PCB/rigid-flex board ODM/OEM. The content is structured to prioritize key technologies, with clear technical details and actionable strategies.

1. Introduction: The Criticality of FPC Impedance Stability in Humid Conditions

Flexible Printed Circuits (FPCs) are foundational to 5G devices, automotive infotainment, and medical wearables—yet high-humidity environments (60%+ RH) trigger catastrophic impedance drift. This drift stems from two core issues:

Dielectric constant (DK) fluctuation: Moisture absorption elevates substrate DK (e.g., from 2.1 to 2.8 for standard PI), disrupting characteristic impedance (Z₀ = √(L/C)) .

Conductor degradation: Humidity accelerates copper oxidation and ion migration, increasing series resistance and destabilizing differential impedance .

Uncontrolled drift causes signal reflection, crosstalk, and field failures—costing manufacturers millions in recalls. Below, we break down engineering solutions and how Shenzhen Huaruixin Electronics, a leading FPC ODM/OEM, solves this challenge.

2. EDA-Centric Strategies for Humidity-Resistant FPC Impedance Control

Electronic design engineers must embed moisture resilience into material selection, layout, and validation to maintain impedance control precision (±5% for 5G applications) . Here are the prioritized steps:

2.1 Select Low-Moisture-Absorption Substrates (Foundational Fix)

Substrate choice directly dictates humidity resistance—prioritize materials meeting IPC-2221 moisture absorption standards (<0.1% after 24h immersion) :

LCP (Liquid Crystal Polymer): Ideal for high-frequency FPCs, with DK 2.9@10GHz and water absorption <0.04% .

PTFE (Polytetrafluoroethylene): Critical for RF FPCs, offering DK stability (2.1–2.3) and moisture absorption <0.01% .

Modified PI: Cost-effective alternative with hydrophobic additives (e.g., silica nanoparticles), reducing absorption from 1.5% to <0.5% .

2.2 Optimize Conductor Design & Surface Finishes

Etching tolerance and plating uniformity directly impact impedance—pair precision design with corrosion-resistant coatings:

Oxygen-Free Copper (OFC) conductors: 99.99% purity minimizes oxidation-driven resistance shifts .

ENIG (Electroless Nickel Immersion Gold): 2–5μm nickel barrier + 0.1μm gold layer blocks moisture, passing 1000h 85°C/85% RH testing .

ImAg with anti-tarnish coating: Cost-effective for consumer electronics, but requires acrylic topcoats to prevent silver migration .

2.3 Reinforce with Moisture Barriers & Structural Design

Physical barriers prevent moisture ingress—critical for rigid-flex boards and edge-exposed FPCs:

Hydrophobic coverlays: Polyimide/PET coverlays with fluoropolymer-modified adhesives seal substrate edges .

Via sealing: Epoxy potting or solder mask fills via holes to stop moisture seepage into inner layers .

2.4 Validate with Humidity-Impedance Testing (Non-Negotiable)

Follow IPC-TM-650 and IEC-60068 standards to simulate real-world conditions :

85°C/90% RH constant testing: 1000h exposure with impedance measured via Keysight E5063A (acceptance: Z₀ drift <±3%) .

Thermo-humidity cycling: -55°C to 125°C, 1000 cycles—ensures DK stability and no delamination .

Ion migration testing: 40°C/90% RH, 60VDC for 1000h—eliminates short-circuit risks .

3. Huaruixin’s Industry-Leading High-Humidity FPC Solutions

As a global FPC/PCB ODM/OEM, Huaruixin integrates IPC-compliant processes and custom engineering to deliver humidity-resistant FPCs with <±3% impedance drift. Our core capabilities:

3.1 Custom Substrate Formulation (Our Competitive Edge)

Partner-driven material development: Collaborate with DuPont/Toray to create PI-LCP blends with DK 2.4@10GHz and moisture absorption <0.3%—ideal for automotive FPCs (85°C/95% RH, 2000h durability) .

Stringent IQC: 100% batch testing per IPC-TM-650 2.6.2.1—rejecting substrates with absorption >0.5% .

3.2 Precision Manufacturing with Environmental Control

Class 1000 cleanrooms: 40–50% RH production environment reduces substrate DK variation by 30% vs. standard facilities .

LDI-enabled etching: Laser direct imaging achieves ±2μm etching tolerance—critical for maintaining differential impedance in dense FPC layouts .

3.3 ISO 17025-Accredited Humidity Testing

Our in-house lab exceeds industry standards:

Extended 95°C/95% RH testing: 3000h for medical FPCs (e.g., wearable monitors) with Z₀ drift <±3% .

Failure analysis: SEM/EDS imaging identifies moisture ingress points to optimize coverlay design for repeat clients .

3.4 Full-Lifecycle Traceability & Support

Serialized quality tracking: Every FPC links to substrate batches, plating parameters, and test data for rapid root-cause analysis .

Design-for-humidity reviews: Our EDA team optimizes trace width/spacing and material choices before prototyping—reducing development time by 20%.

4. Partner with Huaruixin for Humidity-Resistant FPCs

If your project demands stable impedance in high-humidity environments (automotive, 5G, medical), Huaruixin’s ODM/OEM services deliver turnkey solutions:

Technical resources: Visit www.hrxfpc.com for FPC impedance control guides and humidity-test case studies.

Expert consultation: Email sales@hrxfpc.com to discuss custom substrates, ENIG finishes, or IPC-compliant testing.

We ensure your FPCs meet global standards and outperform in harsh conditions.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP