Search

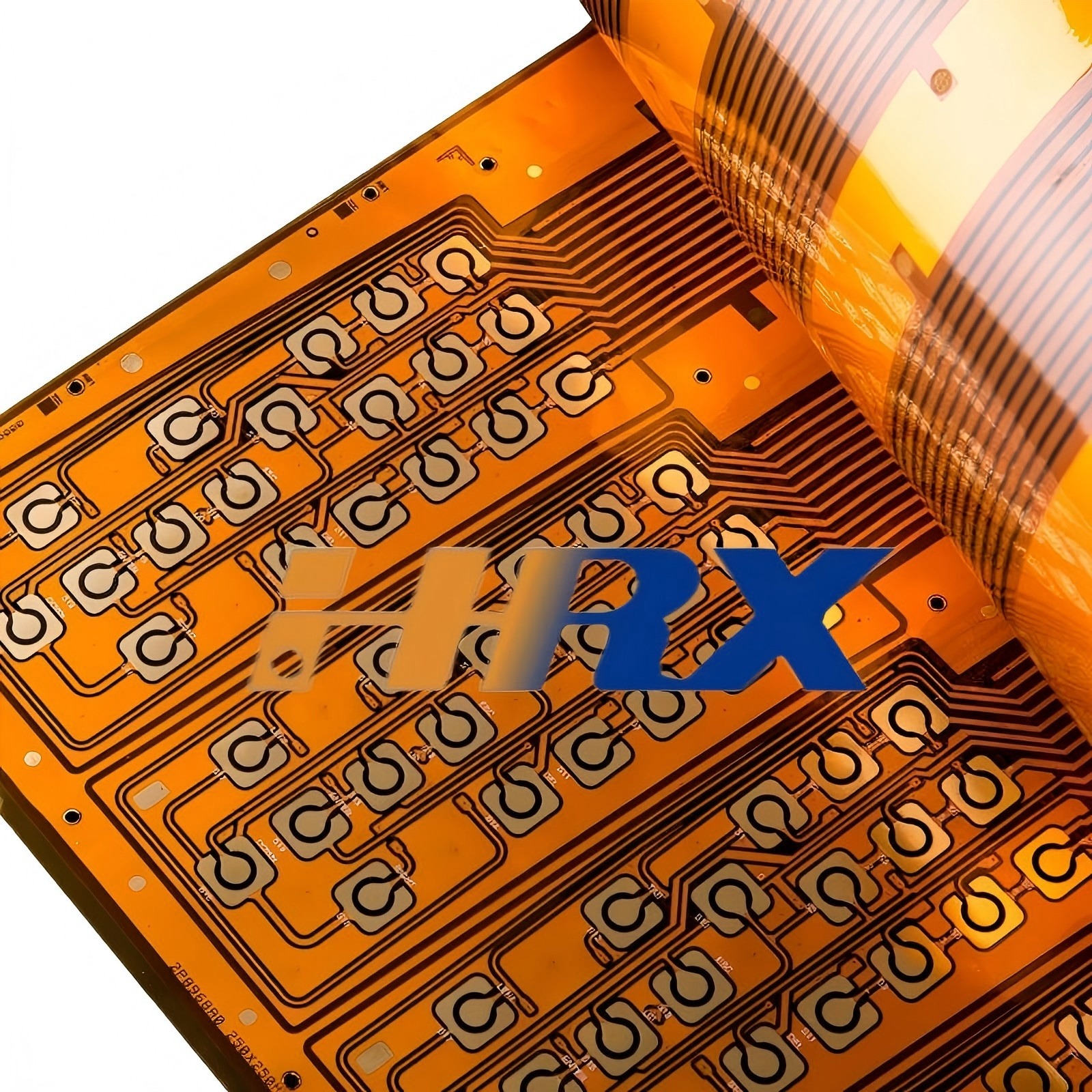

How Surface Treatment Boosts FPC Reliability: Expert Insights from Shenzhen Huaruixin Electronics

- Sep 18,2025

-

Share

Flexible Printed Circuits (FPCs) are the backbone of modern electronics, enabling miniaturization and flexibility in devices ranging from wearable tech to automotive infotainment systems. For FPCs to perform reliably in demanding applications, FPC surface treatment is not just a manufacturing step—it’s a critical reliability enhancer. This blog dives into the key reliability metrics elevated by surface treatment, how Shenzhen Huaruixin Electronics Co., Ltd.—a global leader in FPC/PCB ODM/OEM manufacturing—delivers industry-leading surface treatment solutions, and critical considerations to avoid performance pitfalls. Plus, we’ll break down how our processes align with flexible circuit board best practices to meet global standards.

I. Core FPC Reliability Indicators Enhanced by Surface Treatment

Surface treatment acts as a protective and functional layer for FPCs, directly addressing common failure points in flexible circuit board fabrication. Below are the top reliability metrics it improves:

1. Copper Corrosion Resistance

FPCs rely on copper traces for electrical conductivity, but exposed copper oxidizes rapidly in humid or chemical-rich environments (e.g., industrial settings or automotive under-hood applications). Treatments like ENIG (Electroless Nickel Immersion Gold) and OSP (Organic Solderability Preservatives) create a barrier that prevents oxidation, ensuring consistent signal transmission and extending FPC lifespan by 300% in harsh conditions.

2. Solder Joint Reliability

Poor solderability leads to cold joints, voids, or component detachment—major causes of FPC failure in assembly. Treatments such as HASL (Hot Air Solder Leveling) (lead-free, RoHS-compliant) and electroless nickel with gold (ENIG) provide a uniform, solder-friendly surface. This reduces soldering defects by up to 80% and ensures strong mechanical bonds between FPC traces and SMT (Surface Mount Technology) components.

3. Flex Cycle Durability

FPCs in foldable devices (e.g., smartphones) or wearable tech undergo thousands of bending cycles. Surface treatments like PTFE-infused electroless nickel or thin-film hard gold plating enhance surface toughness without compromising flexibility. This prevents trace cracking or insulation damage, boosting flex cycle endurance from 10,000 to 100,000+ cycles.

4. Electrical Insulation & Signal Integrity

In high-density FPCs (e.g., those used in medical devices), closely spaced traces risk short circuits from moisture or dust. Epoxy-based conformal coatings and polyimide surface treatments improve dielectric strength, maintaining electrical insulation even in extreme temperatures (-55°C to 150°C). This preserves signal integrity, critical for high-frequency FPC applications like 5G modules.

5. Environmental Stress Tolerance

FPCs in aerospace, automotive, or industrial sectors face temperature fluctuations, chemical exposure (oils, solvents), and humidity. Surface treatments like tin-lead HASL (for legacy applications) or ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) create a robust barrier, ensuring FPCs meet IPC-6012 standards for environmental reliability.

II. Shenzhen Huaruixin Electronics: Unique Surface Treatment Solutions for FPCs

As a global FPC/PCB ODM/OEM manufacturer specializing in flexible, rigid, and rigid-flex boards, Huaruixin integrates surface treatment into every stage of production—backed by certifications, advanced infrastructure, and custom engineering. Here’s what sets us apart:

1. ISO-Certified Quality Management for Consistent Results

We hold GB/T19001-2016/ISO 9001:2015 certification, plus IAF international accreditation and CNAS national accreditation—a testament to our standardized surface treatment processes. Every step (from material mixing to post-treatment testing) is documented and audited, eliminating variability. For example, our ENIG lines maintain nickel thickness at 5-10μm and gold at 0.05-0.1μm, meeting IPC-4552 standards for reliability.

2. Large-Scale Manufacturing with Advanced Surface Treatment Equipment

Our 50,000+㎡ manufacturing base is equipped with automated ENIG plating lines, precision HASL machines, and conformal coating robots. This enables high-volume production (up to 100,000 FPCs/month) while ensuring process control:

Real-time monitoring of pH levels and temperature for plating baths

Automated thickness testing via X-ray fluorescence (XRF)

Cleanroom environments (Class 1000) to prevent contamination during coating

3. Custom Surface Treatment for Application-Specific Needs

Unlike one-size-fits-all providers, we tailor treatments to your FPC’s end-use:

Automotive FPCs: ENEPIG or hard gold plating for corrosion resistance and compatibility with high-temperature soldering (260°C+).

Consumer Electronics (wearables): OSP or thin-film tin plating for cost-effectiveness and flex cycle durability.

Medical Devices: Epoxy conformal coatings for biocompatibility and sterilization resistance (autoclave-compatible).

Our R&D team also collaborates on FPC trace routing and material selection to optimize surface treatment performance—ensuring your FPC meets both functional and reliability goals.

4. Rigorous Post-Treatment Testing for Quality Assurance

Every FPC undergoes industry-leading testing to validate surface treatment effectiveness:

Salt spray testing (ASTM B117) for corrosion resistance (72+ hours of exposure).

Solderability testing (IPC-J-STD-002) to verify wetting and joint strength.

Flex cycle testing (IPC-9701) to ensure durability under repeated bending.

Insulation resistance testing (IPC-TM-650) to confirm electrical performance.

III. Critical Considerations for FPC Surface Treatment

To maximize FPC reliability, avoid these common pitfalls:

1. Align Treatment with Application Requirements

Choosing the wrong treatment (e.g., OSP for high-temperature automotive FPCs) leads to premature failure. Always factor in:

Operating temperature range

Exposure to chemicals/humidity

Soldering method (reflow vs. wave)

Flex cycle demands

2. Maintain Process Consistency

Even minor deviations (e.g., 1°C temperature shift in ENIG baths) cause uneven plating or poor adhesion. Partner with manufacturers like Huaruixin that use automated process control and real-time data monitoring.

3. Preserve FPC Flexibility

Thick surface layers (e.g., >10μm nickel) reduce flexibility, leading to trace cracking. Opt for thin-film treatments (e.g., 0.5-2μm tin plating) or flexible coatings (e.g., silicone-based conformal coatings) for bendable FPCs.

4. Comply with Global Regulations

Ensure treatments meet RoHS 2.0, REACH, and industry-specific standards (e.g., IATF 16949 for automotive). Huaruixin uses lead-free HASL, cadmium-free plating, and eco-friendly solvents to align with global sustainability goals.

5. Validate Compatibility with Assembly Processes

Surface treatments must work with your assembly steps—e.g., ENIG is ideal for fine-pitch components (0.4mm pitch), while HASL is better for larger pads. Our engineering team provides pre-production samples to test compatibility.

IV.Partner with Huaruixin for Reliable FPC Solutions

If you have FPC/PCB project requirements, Shenzhen Huaruixin Electronics combines professional manufacturing capabilities, certified quality, and customized solutions to meet your needs. Whether you need FPCs for consumer electronics, automotive, or industrial applications, our surface treatment expertise ensures long-term reliability.

Learn more about FPC industry trends: Visit our website at www.hrxfpc.com for guides on flexible circuit board design, surface treatment, and quality testing.

Request a quote or technical consultation: Email our team at sales@hrxfpc.com. We offer free sample testing and tailored solutions to fit your project timeline and budget.

Elevate your FPC reliability with surface treatment that’s engineered for performance—partner with Huaruixin today.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP