Search

High-Speed High-Frequency FPC: Key Applications, Design Essentials, and Industry Layout – Expert Insights by Shenzhen Huaruixin Electronics

- Aug 27,2025

-

Share

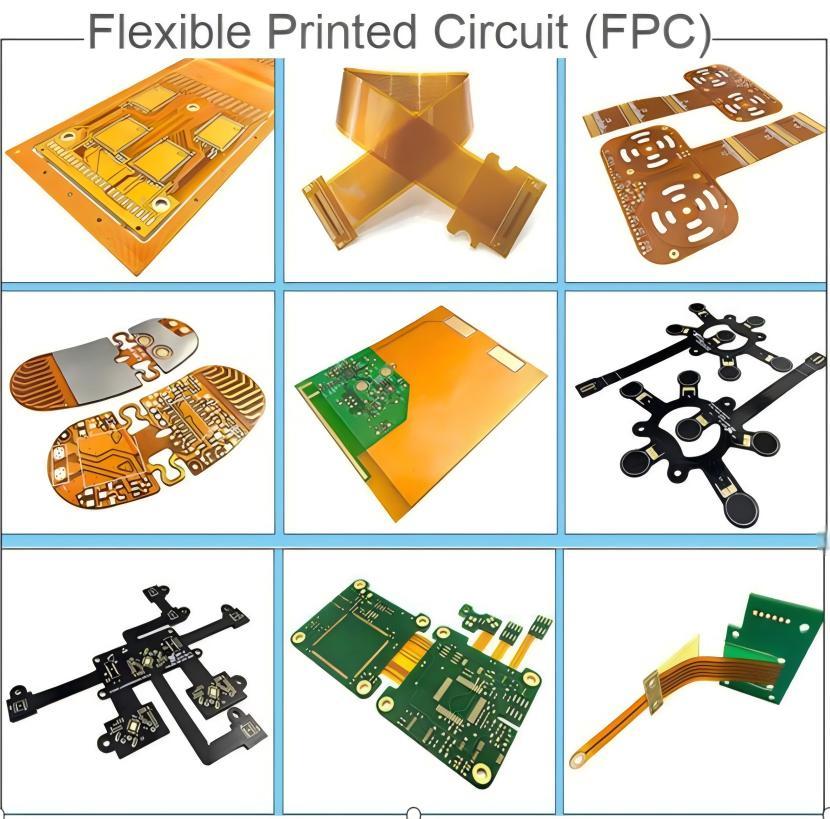

In the age of 5G, AI, and smart manufacturing, High-Speed High-Frequency FPC has become a cornerstone of high-performance electronic devices. Unlike standard Flexible Printed Circuits (FPC), these specialized FPCs are engineered to transmit signals at ultra-high speeds (≥10Gbps) and frequencies (≥1GHz) with minimal insertion loss (IL) and crosstalk, making them indispensable across tech-driven industries. As a global ODM/OEM leader in FPC, PCB, and Rigid-Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. leverages decades of expertise to address the unique challenges of High-Speed High-Frequency FPC design, production, and quality control. This blog dives into their top industry applications, critical technical considerations, strategic market layout, and rigorous QC processes—optimized to help you understand and source reliable High-Speed High-Frequency FPC solutions.

I. Leading Industries Driving Demand for High-Speed High-Frequency FPC

High-Speed High-Frequency FPC is not a niche component; it is a backbone of industries where signal integrity (SI), flexibility, and miniaturization are non-negotiable. Below are the sectors with the highest adoption, paired with SEO-focused use cases:

1. 5G Communications & Telecommunications

The 5G ecosystem (from base stations to end devices) relies on High-Speed High-Frequency FPC to achieve ultra-low latency (≤1ms) and multi-Gbps data rates. Key applications include:

5G Active Antenna Units (AAUs): Huaruixin’s FPCs connect RF modules to antennas, transmitting signals in 3.5GHz sub-6GHz and 24-40GHz mmWave bands with dielectric loss (Df) ≤0.002 (using PTFE substrates), critical for minimizing signal attenuation.

5G Smartphones & Tablets: Enabling 5G modem-to-antenna connectivity and supporting 4K/8K video streaming via high-speed interfaces like USB-C 3.2 (10Gbps) or Thunderbolt 4 (40Gbps). Our ultra-thin (0.1mm) FPCs fit slim device form factors without compromising performance.

Satellite & Microwave Communications: Withstanding extreme temperatures (-55°C to 150°C) and vacuum environments, our radar FPCs ensure stable transmission of high-frequency signals (up to 60GHz) for aerospace and defense applications.

2. Consumer Electronics (Smart Wearables, AR/VR)

Consumer tech’s shift toward miniaturization and immersive experiences has amplified demand for High-Speed High-Frequency FPC:

Smart Wearables (Watches, TWS Earbuds): Supporting Bluetooth 5.3 (2Mbps), Wi-Fi 6E (2.4Gbps), and real-time health data (ECG, SpO2) transmission. Huaruixin’s flexible RF FPCs feature bend cycles ≥100,000 (at 90°) and biocompatible cover layers for skin contact.

AR/VR Headsets: Delivering high-resolution (4K+) visual data and motion tracking via DisplayPort 2.1 (80Gbps) and USB4 interfaces. Our FPCs use LCP (Liquid Crystal Polymer) substrates (Dk=2.1-2.3 @ 10GHz) to reduce return loss (RL) and ensure lag-free immersion.

Ultra-HD TVs & Gaming Consoles: Facilitating HDMI 2.1 (48Gbps) and HDMI 3.0 (100Gbps) connections for 8K video and cloud gaming. Our high-speed differential pair FPCs maintain impedance matching (50Ω/100Ω) with ±5% tolerance to avoid signal distortion.

3. Automotive Electronics (EVs, ADAS)

The rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) demands automotive-grade High-Speed High-Frequency FPC that meets IATF 16949 standards:

ADAS Radar & LiDAR Systems: Transmitting high-frequency sensor data (77-81GHz for radar, 905nm for LiDAR) to ECUs with zero latency—critical for collision avoidance. Huaruixin’s FPCs feature EMI shielding (copper/aluminum layers) to block interference from other vehicle systems.

In-Vehicle Infotainment (IVI): Supporting 5G in-car Wi-Fi, V2X (Vehicle-to-Everything) communication, and 4K rear-seat displays. Our FPCs withstand temperature cycling (-40°C to 125°C) and vibration (10-2000Hz) per ISO 16750.

EV Battery Management Systems (BMS): Transmitting real-time battery voltage/current data at 1Mbps via CAN FD protocol. Our high-temperature FPCs use PI (Polyimide) substrates with thermal conductivity ≥0.3W/m·K to prevent overheating.

4. Medical Electronics (Diagnostic & Wearable Devices)

Medical devices require biocompatible, high-reliability High-Speed High-Frequency FPC that complies with ISO 10993 and FDA standards:

Ultrasound & MRI Equipment: Transmitting high-frequency imaging signals (10-20MHz for ultrasound) with minimal signal degradation. Huaruixin’s FPCs use adhesive-free LCP layers to reduce acoustic interference.

Wearable Medical Monitors: Supporting continuous data transmission (e.g., ECG, glucose levels) to hospitals via BLE 5.4 or 5G. Our FPCs are autoclavable (134°C, 20psi) and resistant to bodily fluids.

Minimally Invasive Surgical Tools: Enabling flexible wiring in endoscopes and robotic arms. Our microvia FPCs (via diameter ≥50μm) reduce size while maintaining high-speed signal transmission (≥5Gbps).

5. Industrial Automation & IoT

Industrial IoT (IIoT) and smart factories rely on rugged High-Speed High-Frequency FPC for seamless connectivity:

Industrial Sensors (Pressure, Vibration): Transmitting data to cloud platforms via Ethernet/Profinet (1Gbps) or 5G NB-IoT. Our FPCs resist dust, moisture (IP67), and chemicals per IEC 60068.

Robotic Arms & Automation Equipment: Withstanding dynamic bending (10,000+ cycles) while supporting EtherCAT (100Mbps) for real-time motion control. Huaruixin’s reinforced FPCs (stainless steel stiffeners) prevent trace cracking.

II. Critical Design & Production Factors for High-Speed High-Frequency FPC

Designing and manufacturing High-Speed High-Frequency FPC requires precision—even micron-level deviations can compromise signal integrity. Huaruixin prioritizes these technical pillars, optimized for both performance and SEO relevance:

1. Substrate & Material Selection: The Foundation of Signal Performance

Material choice directly impacts dielectric constant (Dk), dissipation factor (Df), and thermal stability—key metrics for high-speed signals:

Base Substrates:

PTFE (Polytetrafluoroethylene): Ideal for frequencies ≥10GHz (Dk=2.1, Df≤0.002 @ 10GHz) – used in 5G mmWave and satellite FPCs.

LCP (Liquid Crystal Polymer): Best for 1-10GHz signals (Dk=2.1-2.3, Df≤0.004) – perfect for AR/VR and automotive radar FPCs.

High-Tg PI: For industrial/automotive applications (Tg≥280°C) – balances flexibility and thermal resistance.

Copper Foil: High-purity electrolytic copper (99.99%) or rolled copper (for dynamic bending) with surface roughness ≤0.3μm to reduce skin effect (signal concentration on conductor surfaces).

Adhesives & Cover Layers: Low-Df adhesives (acrylic/epoxy, Df≤0.005) and adhesive-free LCP/PTFE cover layers to avoid signal absorption and enhance durability.

2. Signal Integrity (SI) Design: Mitigating Loss and Interference

Signal integrity is make-or-break for High-Speed High-Frequency FPC. Huaruixin uses advanced design tools (ANSYS HFSS, Cadence Allegro) to address:

Impedance Control: Precision design of trace width (30-100μm), trace spacing (≥3x width), and substrate thickness (25-100μm) to maintain characteristic impedance (50Ω for RF, 100Ω for differential pairs) with ±5% tolerance.

Crosstalk Suppression: Implementing stripline/microstrip configurations, ground planes between signal layers, and guard traces to reduce near-end crosstalk (NEXT) by ≥25dB and far-end crosstalk (FEXT) by ≥30dB.

EMI/EMC Compliance: Adding copper mesh shielding or conductive ink coatings to block external electromagnetic interference (EMI) and meet CISPR 22/EN 55022 standards for consumer/automotive devices.

3. Manufacturing Process Precision: Controlling Tolerances

High-Speed High-Frequency FPC requires tighter process controls than standard FPC. Huaruixin’s large-scale manufacturing base uses:

Laser Drilling: Creating microvias (50-100μm diameter) and blind vias with ±5μm accuracy to connect layers without signal loss—critical for dense designs.

Fine-Line Etching: Achieving line width/space (L/S) = 25μm/25μm using automated etching machines (tolerance ±3μm) to support high-speed signal routing.

Automated Optical Inspection (AOI): High-resolution cameras (5μm/pixel) and AI-driven algorithms to detect defects (open circuits, short circuits, burrs) with 99.9% accuracy—reducing rework and improving yield.

Impedance Testing: In-line Time-Domain Reflectometry (TDR) and Vector Network Analyzers (VNA) to measure impedance and S-parameters (S11, S21) at target frequencies (1-60GHz) for every batch.

4. Thermal Management: Preventing Performance Degradation

High-speed signal transmission generates heat, which can increase Df and reduce FPC lifespan. Huaruixin addresses this with:

Thermally Conductive Materials: Integrating graphite films (thermal conductivity ≥300W/m·K) or aluminum core layers into FPC designs to dissipate hotspots.

Thermal Simulation: Using ANSYS Icepak to predict heat distribution and optimize trace routing—avoiding dense trace clusters in high-power areas (e.g., 5G modems).

III. Industry Layout Strategy for High-Speed High-Frequency FPC by Huaruixin

To stay ahead in the competitive High-Speed High-Frequency FPC market, Huaruixin aligns its strategy with global tech trends and customer needs—focused on R&D, global production, and customization:

1. R&D: Leading Innovation for Next-Gen Technologies

Huaruixin invests 8-10% of annual revenue in High-Speed High-Frequency FPC R&D, focusing on:

6G & mmWave FPCs: Collaborating with Dupont and Toray to develop low-loss PTFE/LCP substrates for 6G (100-300GHz) applications—critical for future satellite and 6G base stations.

Automotive Grade FPCs: Certifying FPCs to AEC-Q200 (passive components standard) and developing high-temperature FPCs for EV powertrains (up to 150°C).

Medical FPCs: Designing biocompatible, sterilizable FPCs that meet ISO 10993-5 (cytotoxicity) and ISO 10993-10 (irritation) standards.

2. Global Production & Supply Chain Resilience

To meet global demand for High-Speed High-Frequency FPC, Huaruixin has built a robust network:

Shenzhen Manufacturing Base: 10+ advanced production lines (ISO 9001, IATF 16949 certified) with monthly capacity of 500,000+ High-Speed High-Frequency FPC units.

Regional Support Centers: Located in Germany (Europe), USA (North America), and Vietnam (Southeast Asia) to provide 48-hour technical support, sample testing, and localized logistics.

Material Security: Long-term partnerships with Dupont (PTFE), Toray (LCP), andJX Nippon Mining (copper foil) to ensure stable supply of critical materials—even during market fluctuations.

3. Customization: Tailored Solutions for Niche Industries

Every industry has unique High-Speed High-Frequency FPC needs. Huaruixin’s 50+ senior engineers (10+ years of FPC experience) offer:

End-to-End Design Services: From schematic design and 3D EM simulation to prototype testing—ensuring FPCs meet your exact signal speed, frequency, and form factor requirements.

Rapid Prototyping: 3-5 day turnaround for High-Speed High-Frequency FPC samples (minimum order quantity: 1 piece) to accelerate your product development cycle.

Turnkey Solutions: Integrating SMT (Surface Mount Technology) assembly, connector soldering, and final testing (e.g., thermal cycling, vibration) to deliver ready-to-use FPC modules.

IV. Quality Control (QC) for High-Speed High-Frequency FPC: Huaruixin’s Rigorous Process

High-Speed High-Frequency FPC has zero tolerance for defects. Huaruixin implements a three-stage QC system (per IPC-6012/2223 standards) to ensure reliability:

1. Incoming Material Inspection (IMI)

All raw materials undergo strict testing before production:

Substrate Testing: Measuring Dk/Df (using Keysight E4990A impedance analyzer) and tensile strength (per IPC-TM-650 2.4.18) to verify compliance.

Copper Foil Testing: Checking purity (X-ray fluorescence) and surface roughness (atomic force microscopy) to ensure low signal loss.

Traceability: Assigning unique batch numbers to all materials—enabling full traceability if quality issues arise.

2. In-Process Quality Control (IPQC)

Real-time monitoring at every production step:

Etching QC: AOI systems inspect line width, spacing, and burrs—rejecting any FPC with deviations >±3μm.

Impedance Testing: TDR/VNA testing for 5% of FPCs per batch—ensuring impedance tolerance ≤±5%.

Bending Testing: Dynamic bending tests (10,000+ cycles at 90°) for flexible applications—verifying no trace cracking or signal degradation.

3. Final Quality Control (FQC)

Comprehensive testing before shipment:

Electrical Performance: Continuity tests (100% coverage), insulation resistance (≥100MΩ @ 500V DC), and S-parameter measurement (1-60GHz) to confirm insertion loss ≤0.5dB/inch at 10GHz.

Environmental Reliability:

Thermal cycling: -40°C to 125°C, 100 cycles (per IPC-TM-650 2.6.7).

Humidity testing: 85% RH, 85°C, 500 hours (per IPC-TM-650 2.6.3.7).

Salt spray testing: 5% NaCl, 35°C, 48 hours (for automotive/industrial FPCs).

Visual & Dimensional Inspection: CMM (Coordinate Measuring Machine) checks for dimensional accuracy (±0.05mm) and visual inspection for scratches/stains.

V. Partner with Huaruixin for Your High-Speed High-Frequency FPC Needs

If you’re searching for a reliable High-Speed High-Frequency FPC manufacturer that combines technical expertise, global capacity, and strict quality control, Shenzhen Huaruixin Electronics is your trusted partner. We specialize in custom solutions for 5G, automotive, medical, and industrial applications—delivering FPCs that meet IPC, IATF 16949, and FDA standards.

Project Inquiries: For customized High-Speed High-Frequency FPC solutions (e.g., 5G mmWave FPC, ADAS Radar FPC, Medical FPC), contact our sales team anytime.

Industry Resources: Visit our website www.hrxfpc.com to access FPC technical whitepapers, case studies, and certification documents—optimized to help you learn more about High-Speed High-Frequency FPC design and applications.

Technical Exchange: Email sales@hrxfpc.com to discuss your project requirements, request sample testing, or exchange insights on the latest High-Speed High-Frequency FPC technologies.

At Huaruixin, we’re committed to powering your innovation with high-quality, high-performance FPC solutions.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP