Search

High-Precision FPC Microfabrication: Industry-Leading Applications & Innovations

- Aug 09,2025

-

Share

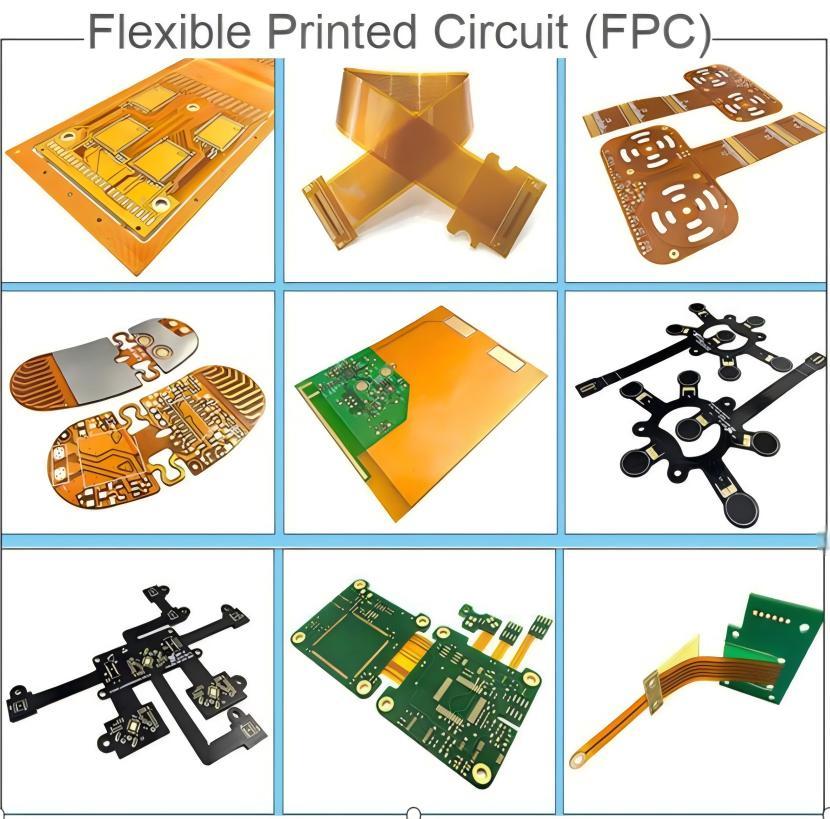

In the age of smart devices and miniaturized electronics, Flexible Printed Circuit (FPC) microfabrication has become an indispensable technology, driving innovation across consumer electronics, automotive engineering, medical devices, and industrial automation. By enabling ultra-fine circuitry, exceptional flexibility, and reliable performance in extreme conditions, FPC microfabrication is redefining product design possibilities. This blog explores cutting-edge applications that highlight the transformative power of advanced FPC manufacturing techniques.

FPC Microfabrication in Consumer Electronics: Powering Compact, High-Performance Devices

Consumer electronics demand smaller, lighter, and more versatile designs—requirements perfectly addressed by high-precision FPC solutions.

Smartphone High-Density FPC Integration: A Benchmark in Miniaturization

Leading smartphone manufacturers like Apple leverage FPC microfabrication to achieve unprecedented component integration. The latest iPhone models feature FPCs with 30μm/30μm line width/space ratios, supporting complex multi-layer architectures (up to 20 layers) that maximize connectivity within tight spatial constraints.

Technical Specifications: These FPCs utilize polyimide (PI) substrates with thicknesses under 0.1mm, enabling seamless integration with curved OLED displays. They boast a dynamic bending endurance of 100,000 cycles without conductor degradation, critical for modern foldable and flexible device designs.

Application Scenario: Over 20 individual FPCs per device connect key components, including camera modules, touch sensors, and wireless charging coils. Camera assemblies employ Chip-on-Film (COF) packaging, achieving ultra-fine 0.4mm pad pitches to enable high-speed data transfer between image sensors and the main logic board.

Wearable Technology FPC Solutions: Merging Comfort and Performance

Smartwatches and fitness trackers rely on FPC microfabrication to deliver unobtrusive, durable designs without sacrificing functionality.

Technical Specifications: These devices feature FPCs with 25μm minimum line widths produced via advanced roll-to-roll (R2R) etching processes, with overall thicknesses as low as 0.03mm. They support 1.5mm bending radii, enabling 360° wraparound display integration.

Application Scenario: Circular smartwatch displays integrate FPCs that combine touch sensing and display driver circuits, eliminating bulky connectors. Health-focused models incorporate FPC-based Ag/AgCl electrodes with a 40dB signal-to-noise ratio (SNR), meeting medical-grade monitoring standards.

Value Impact: FPC integration reduces wearable device thickness by 60% while improving durability, with 100,000 bending cycles resulting in impedance fluctuations of less than 2%—a key metric for "flexible circuit reliability" searches.

Automotive FPC Applications: Reliability in Extreme Operating Environments

The automotive industry depends on FPC microfabrication for its ability to withstand temperature extremes, vibrations, and space constraints—essential for electric vehicles (EVs) and advanced driver-assistance systems (ADAS).

EV Battery Management System (BMS) FPCs: Enhancing Safety and Efficiency

Tesla’s BMS exemplifies high-reliability FPC implementation for battery monitoring and optimization:

Technical Specifications: These FPCs operate across a -40℃ to 125℃ temperature range, utilizing ceramic-filled PI substrates for superior thermal stability. They support 5A continuous current through 35μm copper foils, with voltage sensing accuracy of ±1mV and temperature measurement precision of ±0.5℃.

Application Scenario: Connecting over 2,000 battery cells in 4680 modules, the FPCs enable real-time voltage and temperature monitoring, ensuring balanced charging and preventing thermal runaway. A dual-layer design integrates sensing circuits on one side and 15A protective fuses on the other for enhanced safety.

In-Vehicle Display FPCs: Enabling Immersive Cockpit Experiences

Modern automotive cockpits feature curved, seamless displays powered by ultra-thin FPC technology:

Technical Specifications: These FPCs measure just 18μm thick (12.5μm PI substrate + 12μm copper foil) and maintain 98Ω ±5% differential impedance for reliable LVDS signal transmission. They pass rigorous 20G vibration testing (10-2000Hz), meeting automotive durability standards.

Application Scenario: Curved infotainment screens use FPCs to follow dashboard contours, integrating touch functionality with 120Hz sampling rates for responsive user interaction.

Value Impact: FPCs reduce installation space by 70% compared to rigid PCBs, enabling seamless dashboard integration while improving EMI (electromagnetic interference) resistance by 30dB.

Medical Device FPCs: Precision and Biocompatibility for Critical Applications

Medical devices require FPCs that combine microscale precision with biocompatibility, enabling minimally invasive procedures and reliable implantable technology.

Endoscope FPC Integration: Miniaturization for Enhanced Visualization

Electronic endoscopes leverage FPC microfabrication to achieve sub-millimeter dimensions without compromising performance:

Technical Specifications: Featuring 20μm line widths and 50μm diameter CO₂ laser-drilled vias, these FPCs use biocompatible materials meeting ISO 10993 standards with cytotoxicity rating 0. They support 0.8mm bending radii for navigating complex anatomical pathways.

Application Scenario: 2mm diameter endoscope probes integrate CMOS image sensors and LED drivers via FPCs, delivering 1920×1080 resolution with SNR >45dB. 3D-printed scaffolds combined with FPCs enable precise steerable control of the endoscope tip.

Implantable Pacemaker FPC Electrodes: Long-Term Reliability In Vivo

FPCs have transformed cardiac pacemaker design, offering flexibility and stability for long-term implantation:

Technical Specifications: These ultra-thin (0.05mm) FPCs use medical-grade PI substrates with platinum-iridium alloy conductors. They maintain >10¹²Ω insulation resistance in bodily fluids and demonstrate 5-year performance stability in vivo.

Application Scenario: FPC electrodes connect the pacemaker pulse generator to the heart, delivering precise pacing signals with transmission latency ≤10μs. Integrated temperature sensors monitor myocardial temperature with ±0.1℃ accuracy.

Value Impact: Compared to rigid electrodes, FPC-based designs reduce implant size by 60%, lowering surgical risks while improving signal detection reliability.

Industrial & Communication: FPCs for High-Speed, Rugged Connectivity

Industrial automation and 5G communication rely on FPC microfabrication for high-speed data transmission and durability in demanding environments.

5G Base Station FPC Antennas: Enabling Next-Gen Wireless Networks

5G millimeter-wave (mmWave) technology depends on FPC microfabrication for compact, high-performance antenna arrays:

Technical Specifications: These FPCs feature 25μm/25μm line width/space on liquid crystal polymer (LCP) substrates (Dk=2.9) for low signal loss. They operate at 28GHz with insertion loss ≤0.3dB/cm and maintain performance across -40℃ to 85℃.

Application Scenario: Integrated into 64T64R MIMO arrays, FPC antennas enable beamforming with 5dB higher gain than traditional designs, extending 5G coverage by 30%.

Industrial Robot Joint FPCs: Precision in Motion Control

Robotic automation uses FPCs to enable precise movement and sensing in articulated joints:

Technical Specifications: These rugged FPCs achieve 100 million dynamic bending cycles at 1.5mm radius and survive 50G vibration (50-2000Hz). They operate across -55℃ to 150℃, suitable for factory environments.

Application Scenario: Connecting encoders, servo motors, and strain sensors in robotic arms, FPCs transmit position and torque data with ≤100ns latency, improving motion control precision.

Value Impact: Replacing traditional wiring harnesses with FPCs reduces robot downtime by 90% by eliminating connector failures, significantly boosting manufacturing productivity.

The Future of FPC Microfabrication

As FPC microfabrication advances, innovations like 0.03mm ultra-thin FPCs with 15μm line widths are enabling new possibilities, supporting 0.5mm bending radii for next-gen foldable devices. Emerging materials (self-healing PI, liquid metal conductors) and processes (laser direct imaging, advanced R2R etching) will further expand applications in AR/VR, flexible displays, and IoT sensors.

For engineers and product designers, FPC microfabrication offers unprecedented opportunities to reimagine product form and function. By leveraging the precision and flexibility of modern FPC technology, industries can continue pushing the boundaries of what’s possible in electronics design.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP