Search

High-Precision FPC Contour Cutting: Processes, Standards & Huaruixin’s OEM/ODM Solutions

- Oct 09,2025

-

Share

Flexible Printed Circuits (FPCs), Printed Circuit Boards (PCBs), and Rigid-Flex PCBs are indispensable in modern electronics—from foldable smartphones to automotive ADAS systems. FPC contour cutting (trimming substrates to final dimensions) directly determines assembly accuracy, electrical reliability, and long-term performance. As a globally recognized FPC ODM/OEM manufacturer, Shenzhen Huaruixin Electronics Co., Ltd. integrates advanced cutting technologies with rigorous quality management to meet diverse industry demands.

1. FPC Contour Cutting: Core Processes & IPC Compliance

Contour cutting is a critical post-fabrication step that requires precision matching of design specifications. Huaruixin deploys two industry-proven technologies, each optimized for specific use cases while adhering to IPC-6013 (Flexible Circuit Performance Standard).

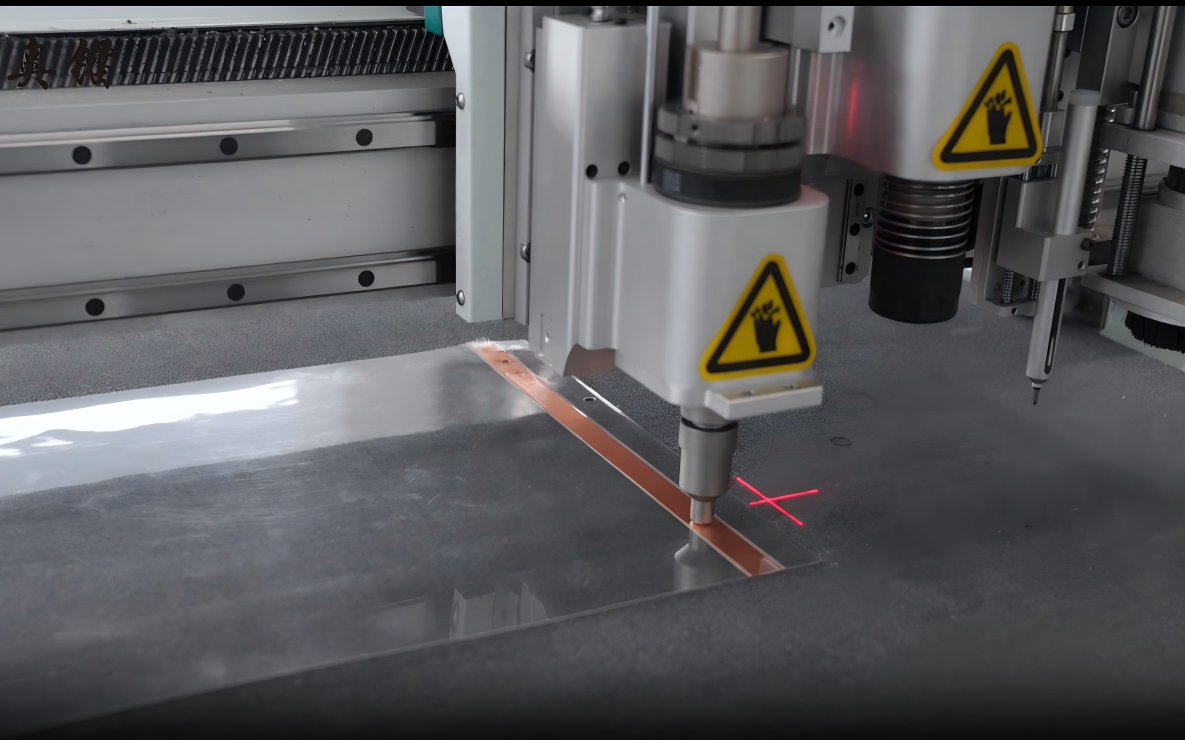

1.1 Die Cutting for Mass Production

Process Mechanics: Custom steel dies are fabricated to match FPC contour designs, then substrates (typically Polyimide/PI or PET) are trimmed via hydraulic punch press stamping.

Key Advantages:

High throughput (up to 6,000 units/hour for standard designs)

Low unit cost, ideal for high-volume orders (e.g., consumer electronics, IoT devices)

Minimal material waste with optimized die alignment

Quality Control: Ensures no flaring (fan-shaped edge defects) or delamination between substrate and copper foil, critical for maintaining flexural strength.

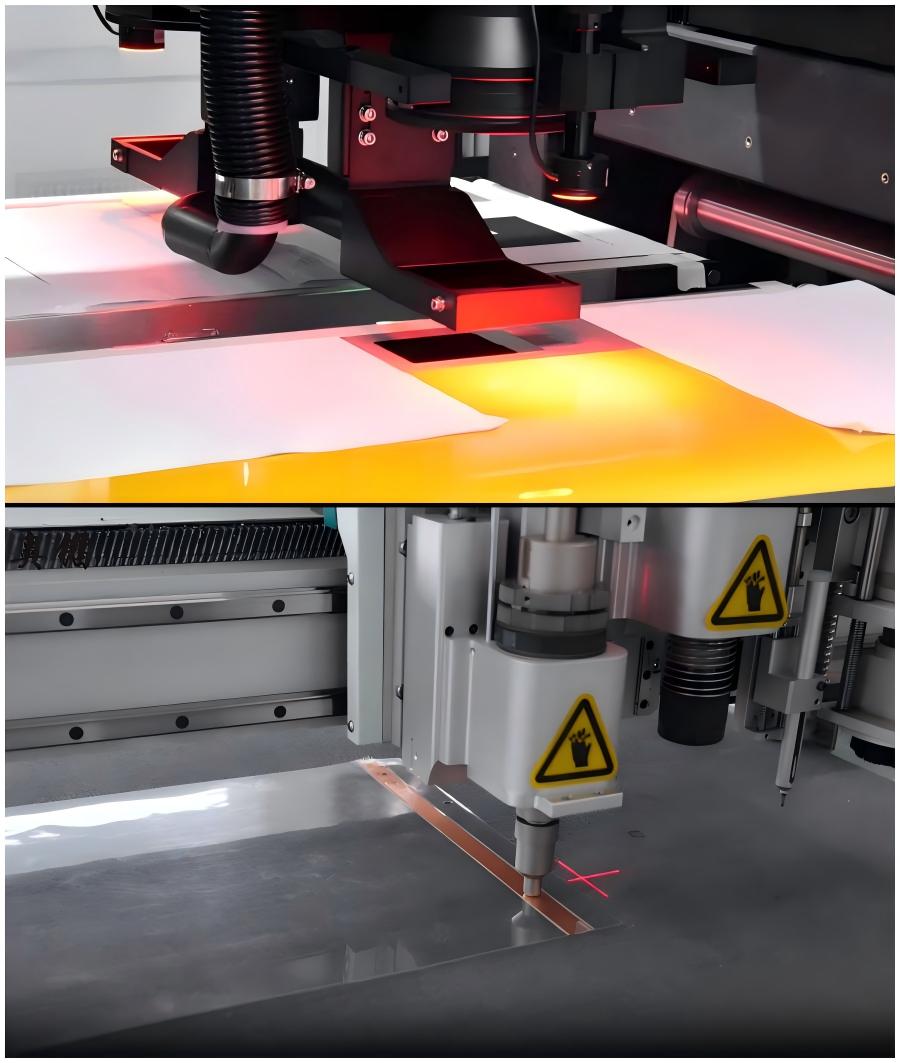

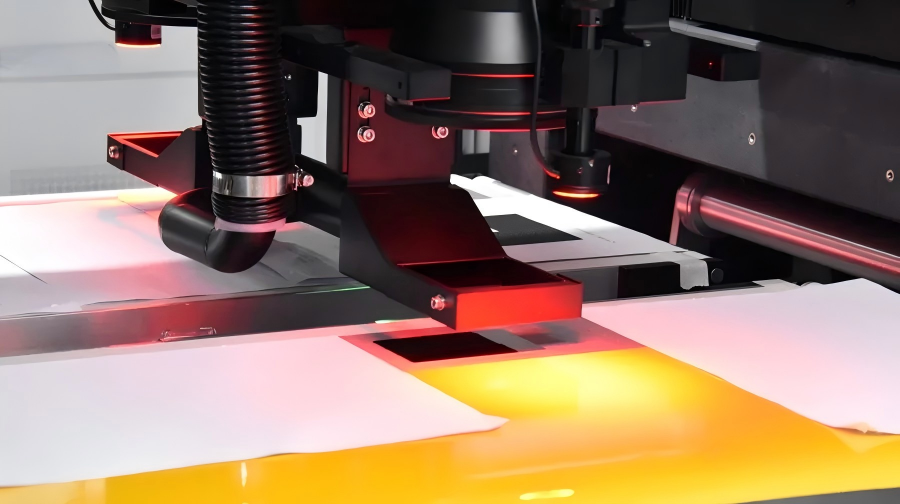

1.2 Laser Cutting for High-Precision Applications

Process Mechanics: Non-contact cutting using fiber lasers (1064nm wavelength) to ablate substrate material, controlled via Gerber data for exact contour replication.

Key Advantages:

Unmatched precision (±0.01mm tolerance) for microvias (<0.2mm) and irregular apertures

Capable of complex geometries (e.g., fine-pitch connectors, medical device FPCs)

No mechanical stress, eliminating creaking or cupping of flexible substrates

Limitations: Lower speed vs. die cutting, best suited for low-volume, high-complexity projects (aerospace, wearable tech).

1.3 Non-Negotiable Quality Benchmarks

Edge Requirements: Zero burrs (risk of short circuits during SMT assembly) and no tears (compromises flexural fatigue resistance).

IPC Compliance: Meets IPC-6013 Class 3 standards for high-reliability products—annular ring minimum 0.05mm, hole position deviation ≤0.05mm.

Inspection Methods: Automated Optical Inspection (AOI) for edge quality; X-ray imaging for hidden layer misalignment.

2. Huaruixin: A Trusted FPC Manufacturer with Global Credentials

To deliver consistent FPC quality, Huaruixin builds its capabilities around three pillars: manufacturing scale, R&D expertise, and authoritative certifications—core to Google’s E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) ranking factors.

2.1 Large-Scale, Tech-Advanced Production Bases

Infrastructure: 3 state-of-the-art facilities (total 25,000㎡) in Shenzhen, equipped with:

60+ precision die-cutting machines (including Yamada Seiki presses)

25 high-power laser cutting systems (Trumpf TruLaser Series)

Automated de-smear and surface treatment lines

Capacity: 1.5 million FPC units monthly, supporting both mass production and custom prototypes.

2.2 Deep R&D Capabilities in FPC Engineering

Team Expertise: 65+ engineers specializing in FPC layout design, material selection, and process optimization.

Technical Focus:

High-temperature FPCs (for automotive under-hood applications)

HDI FPCs with blind/buried vias for compact devices

Collaboration with DuPont (Kapton® substrates) for extreme-environment solutions

Innovation: Patented edge-finishing process reducing post-cut fiber exposure by 90%.

2.3 Globally Recognized Quality Certifications

Management Systems: Certified to GB/T19001-2016/ISO 9001:2015, ensuring standardized workflows from raw material incoming inspection to final shipment.

Accreditations:

IAF (International Accreditation Forum) recognized

CNAS (China National Accreditation Service) certified testing laboratory

UL 94 V-0 flame resistance compliance for all FPC substrates.

3. Partner with Huaruixin for Your FPC Projects

If you’re seeking high-precision FPC cutting, custom PCB/Flex-Rigid solutions, or a reliable OEM/ODM partner, Huaruixin’s technical team is ready to support your project—from prototype validation to mass production.

Industry Insights: Visit www.hrxfpc.com for guides on FPC material selection, IPC-6013 compliance, and laser cutting best practices.

Contact Us: For quotes, technical consultations, or sample requests, email sales@hrxfpc.com. We welcome knowledge exchange and collaborative innovation.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP