Search

HDI Technology in FPC/PCB/Rigid-Flex Boards: Core Features, Critical Roles & Key Implementation Considerations

- Nov 18,2025

-

Share

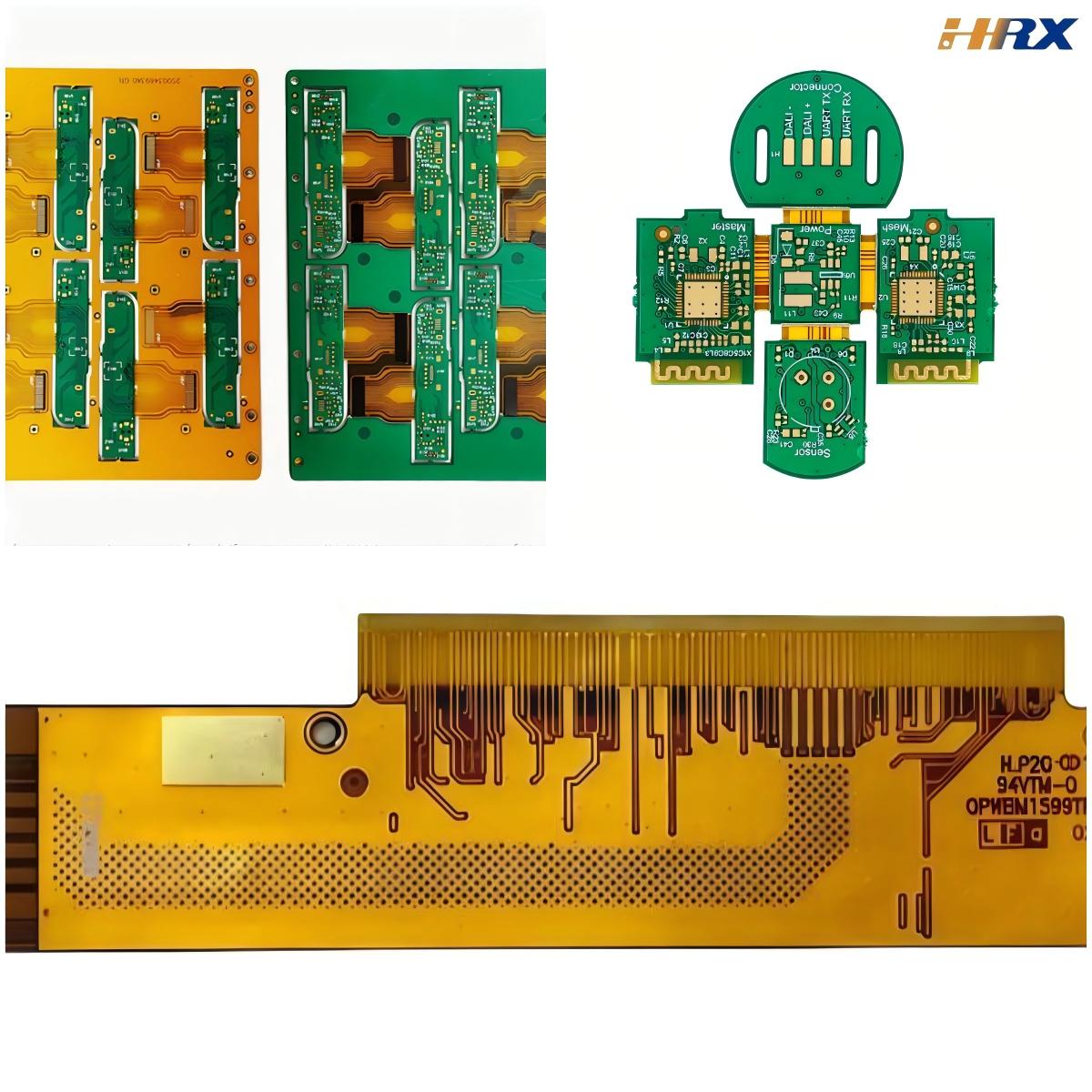

As electronic devices trend toward miniaturization, high performance, and multi-functionality, High-Density Interconnect (HDI) technology has become a cornerstone in the FPC (Flexible Printed Circuit), PCB (Printed Circuit Board), and rigid-flex board industries. Shenzhen Huaruixin Electronics Co., Ltd., a global ODM/OEM manufacturer with extensive experience in HDI-based FPC/PCB/rigid-flex board production, shares professional insights into HDI’s technical characteristics, pivotal roles, and critical considerations for design, production, and quality control—backed by real-world application cases.

1. Core Features of HDI Technology in FPC/PCB/Rigid-Flex Boards

HDI technology revolutionizes interconnect design by maximizing routing density and minimizing board footprint, with distinct traits tailored to flexible, rigid, and hybrid substrates:

Microvia Architecture: Utilizes blind vias (connecting surface layers to inner layers), buried vias (connecting inner layers exclusively), and stacked/stitched microvias (diameter ≤150μm) to eliminate through-holes, reducing board thickness by 30-50% compared to traditional PCBs. For FPCs, laser-drilled microvias (≤80μm) preserve flexibility without compromising structural integrity.

Fine Line/Space (L/S) Capability: Achieves ultra-fine line widths and spaces down to 25μm/25μm (even 15μm/15μm for high-end HDI FPCs), enabling 2-3x higher component density. Huaruixin’s HDI rigid-flex boards for wearable devices, for example, integrate 30μm/30μm L/S to accommodate miniaturized sensors and ICs.

High Layer Count Integration: Supports 4-20+ layer stacks with optimized interconnection, ideal for complex rigid-flex designs (e.g., foldable phone hinges) where signal paths switch between rigid and flexible segments.

Enhanced Thermal & Signal Performance: Reduced via pitch and shorter trace lengths minimize signal attenuation, crosstalk, and electromagnetic interference (EMI), while improved heat dissipation channels (via thermal vias) suit high-power applications like 5G base station PCBs.

Substrate Compatibility: Adapts to diverse materials, including FR-4 (rigid HDI PCBs), PI (Polyimide, for HDI FPCs), and hybrid PI-FR4 (rigid-flex HDI boards), ensuring versatility across consumer electronics, automotive, and aerospace sectors.

2. Critical Roles of HDI Technology in FPC/PCB/Rigid-Flex Applications

HDI is not just a manufacturing upgrade—it directly enables the functionality of next-gen electronic products, with three indispensable roles:

2.1 Enabling Miniaturization & Lightweight Design

As devices like smartwatches, drones, and medical wearables demand smaller footprints, HDI’s microvia and fine L/S capabilities reduce board size by up to 40%. Huaruixin’s HDI FPC for a portable ultrasound device, for instance, integrated 8 layers of PI substrate with stacked microvias, cutting the board area by 35% while maintaining 128 signal channels.

2.2 Enhancing Signal Integrity (SI) & Reliability

In high-speed applications (e.g., 5G modules, PCIe 5.0 interfaces), HDI’s shortened trace paths and reduced via inductance minimize signal delay and jitter. For automotive rigid-flex HDI boards, Huaruixin’s design eliminated through-holes in flex-rigid transition zones, improving bending fatigue resistance by 200% (passing 10,000+ flex cycles).

2.3 Supporting High-Density Component Packaging

HDI enables direct mounting of BGA (Ball Grid Array), CSP (Chip Scale Package), and QFN (Quad Flat No-Lead) components with pitch ≤0.4mm. Huaruixin’s HDI PCB for a 5G router integrated a 0.3mm-pitch BGA IC using stacked microvias, achieving 2x the I/O density of traditional PCBs.

2.4 Optimizing Rigid-Flex Hybrid Performance

For rigid-flex boards (e.g., foldable phone inner hinges), HDI ensures seamless signal transition between rigid (component-mounted) and flexible (bendable) segments. Huaruixin’s HDI rigid-flex solution for a foldable tablet used blind microvias in flex regions, reducing bending stress and extending product lifespan by 30%.

3. Key Considerations for HDI FPC/PCB/Rigid-Flex: Design, Production & Quality Control

3.1 Design Phase: DFM (Design for Manufacturability) & Performance Optimization

Microvia Placement: Avoid microvia clusters in FPC bend zones; maintain ≥2x via diameter spacing to prevent material cracking. Huaruixin’s DFM team revises 15-20% of customer designs to optimize via distribution, reducing production defects by 40%.

Layer Stackup Design: For HDI FPCs, use symmetric PI layer stacks to balance flexibility and stability; for rigid HDI PCBs, integrate ground planes adjacent to signal layers to minimize EMI. Example: A 12-layer HDI rigid-flex board for aerospace required a 4-flex-8-rigid stackup with staggered microvias to meet both signal integrity and weight requirements.

Pad & Trace Design: Match microvia pad sizes to laser drilling capabilities (e.g., 100μm via → 200μm pad for PI substrates); use curved traces in FPC HDI to enhance flex durability.

Impedance Matching: Simulate trace impedance (50Ω/100Ω) early in design—Huaruixin uses Ansys SIwave to optimize trace width and spacing, ensuring ≤±5% impedance deviation.

3.2 Production Phase: Process Precision & Material Control

Material Selection: Choose high-Tg PI (Tg ≥280°C) for HDI FPCs in high-temperature environments; select FR-4 with low dielectric loss (Dk ≤3.8) for HDI PCBs in high-speed applications. Huaruixin sources UL-certified materials to ensure consistency across batches.

Microvia Drilling: Use UV laser drilling for PI substrates (accuracy ±5μm) and CO2 laser for FR-4; control drill depth to avoid over-drilling inner layers. For a medical HDI FPC, Huaruixin achieved 70μm microvias with 99.8% drilling accuracy.

Plating Quality: Implement electrolytic copper plating for microvia filling (copper thickness ≥20μm) to ensure conductivity; use electroless nickel immersion gold (ENIG) or OSP (Organic Solderability Preservative) for surface finish. Huaruixin’s pulse-plating technology reduces via voids to <1%.

Lamination Process: For rigid-flex HDI, use controlled-pressure lamination (1.2-1.5MPa) to bond PI and FR-4 layers without delamination. Example: A 6-layer HDI rigid-flex board required 3 lamination cycles with temperature ramps of 2°C/min to prevent warpage.

3.3 Quality Control: Comprehensive Testing & Validation

Non-Destructive Testing (NDT): Use AOI (Automatic Optical Inspection) for fine trace defects and X-ray inspection (2D/3D) to verify microvia filling and stack integrity. Huaruixin’s X-ray systems detect via voids as small as 5μm.

Electrical Testing: Perform continuity testing, insulation resistance (≥10^10Ω), and impedance testing (using a vector network analyzer) for all HDI boards.

Mechanical & Environmental Validation: For HDI FPCs, conduct flex cycle testing (10,000+ cycles at 180° bend) and temperature cycling (-40°C to 85°C); for rigid HDI PCBs, test thermal shock resistance. Huaruixin’s HDI FPC for automotive passed 20,000 flex cycles with no signal loss.

Quality Compliance: Adhere to IPC-6012 (PCB) and IPC-2223 (FPC) standards; Huaruixin is ISO9001/TS16949 certified, ensuring HDI products meet automotive and industrial-grade requirements.

4. About Shenzhen Huaruixin Electronics Co., Ltd.

With over a decade of ODM/OEM experience in FPC, PCB, and rigid-flex board manufacturing, Huaruixin specializes in high-precision HDI technology—serving global clients in consumer electronics, automotive, medical devices, and aerospace. Our HDI capabilities include:

FPC HDI: Microvias down to 50μm, L/S 15μm/15μm, 2-12 layers.

PCB HDI: Stacked/buried microvias, L/S 25μm/25μm, 4-20 layers.

Rigid-Flex HDI: Hybrid PI-FR4 substrates, 4-16 layers, flex cycle resistance ≥10,000 cycles.

If you have HDI FPC/PCB/rigid-flex project requirements, our engineering team provides end-to-end support—from DFM optimization to mass production. For industry insights, technical resources, or custom quotes, visit our website or contact our sales team:

Website: www.hrxfpc.com

Email: sales@hrxfpc.com

Let’s collaborate to turn your HDI technology needs into reliable, high-performance solutions—together, we drive innovation in electronic interconnects.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP