Search

HASL for FPC: Advantages, Disadvantages, Applications & Key Processing Tips

- Sep 26,2025

-

Share

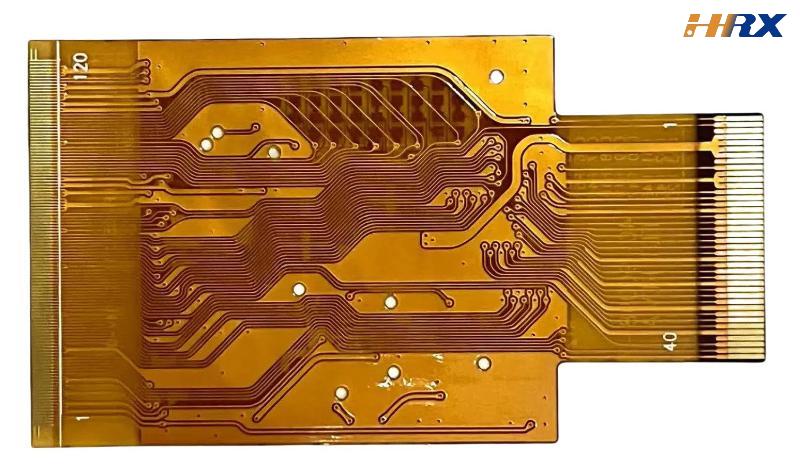

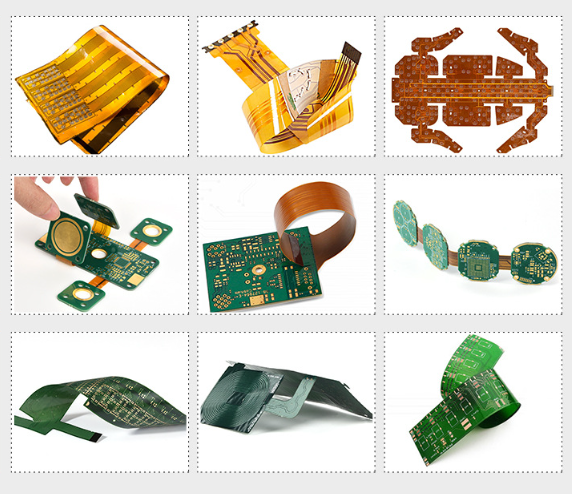

In the flexible printed circuit (FPC) and printed circuit board (PCB) manufacturing industry, surface finishing directly determines solder joint reliability and long-term performance of electronic devices. Among mainstream surface finishing technologies, Hot Air Solder Leveling (HASL) stands out as a cost-effective solution for high-volume FPC production. This guide dives deep into HASL’s core principles, FPC-specific pros and cons, typical use cases, and critical processing considerations—tailored for engineers and procurement teams seeking reliable FPC surface finishing options. As a global leader in FPC, PCB, and rigid-flex board ODM/OEM manufacturing, Shenzhen Huaruixin Electronics Co., Ltd. leverages decades of expertise in HASL and FPC processing to deliver RoHS-compliant, high-quality flexible circuits worldwide.

1. Core Principle of HASL for FPC

Hot Air Solder Leveling (HASL) is a widely used FPC surface finishing process that involves two key steps:

First, the FPC—typically based on polyimide (PI) or polyester (PE) film substrates—is immersed in a molten solder bath (either tin-lead or lead-free alloys like Sn-Cu-Ni or Sn-Ag-Cu). This coats exposed copper pads (including those on multi-layer FPCs) with solder.

Second, high-pressure hot air knives blow across the FPC surface to remove excess solder, forming a uniform, flat tin-based layer with a thickness of 5–15 μm . The result is an oxidation-resistant coating that ensures optimal wetting during SMT assembly and wave soldering, critical for FPCs used in bendable electronic devices.

2. Key Advantages of HASL for FPC Manufacturing

HASL remains a top choice for FPC producers due to unique benefits tailored to flexible circuit requirements:

Cost-Effectiveness for High-Volume FPC Production: Compared to advanced finishes like ENIG (Electroless Nickel Immersion Gold) or ENEPIG, HASL requires simpler equipment and lower material costs . This makes it ideal for mass-produced FPCs in consumer electronics, where cost control directly impacts market competitiveness.

Superior Solderability for Standard FPC Components: The uniform tin layer provides excellent wetting properties, ensuring strong solder joints with standard SMDs (resistors, capacitors) and through-hole components. This minimizes defects like cold joints or voids in FPC assemblies .

Robust Oxidation Protection for FPC Pads: The tin coating acts as a durable barrier, protecting copper pads on PI-based FPCs during storage, transportation, and assembly. This extends the FPC’s shelf life and maintains consistent performance in humid or harsh environments.

Compatibility with FPC Assembly Processes: HASL supports both wave soldering and reflow soldering—two common techniques for FPC assembly. It works seamlessly with standard FPC manufacturing workflows, from coverlay lamination to final electrical testing .

Process Reliability for Flexible Substrates: The mature HASL workflow is easy to control with quality management protocols, reducing variability in solder layer thickness across FPC batches. This consistency is vital for FPCs requiring repeatable performance in bendable applications.

3. Limitations of HASL in FPC Applications

While cost-effective, HASL has constraints that restrict its use in high-performance or precision FPCs:

Non-Uniform Coating on Fine-Pitch FPC Pads: Hot air knives struggle to achieve consistent thickness on FPCs with pad pitches <0.5 mm or dense layouts (e.g., HDI FPCs with microvias). Excess solder can cause bridging, risking short circuits in miniaturized devices .

Lead Compliance Challenges: Traditional tin-lead HASL alloys (e.g., 63Sn/37Pb) violate RoHS regulations in major markets. Lead-free alternatives (e.g., Sn-0.7Cu) are available but increase material costs and require process adjustments for FPCs .

Surface Roughness for High-Precision FPCs: Unlike ENIG or immersion tin, HASL produces a relatively rough surface. This is problematic for FPCs used in wire bonding or high-frequency applications, where signal integrity depends on ultra-flat surfaces .

Thermal Stress on FPC Substrates: The molten solder bath (240–260°C for lead-free alloys) can cause warping or delamination in thin PI FPCs or those with low-Tg materials. This limits HASL use in delicate flexible circuits for wearables or medical devices .

Incompatibility with High-Density FPC Designs: As FPCs trend toward higher wiring density (e.g., for smartphones or IoT devices), HASL’s inability to coat microvias or fine features makes it obsolete. Advanced finishes like ENEPIG are preferred for such applications .

4. Top Application Fields for HASL-Finished FPCs

HASL is best suited for FPCs prioritizing cost and reliability over ultra-precision. Key use cases include:

Standard Consumer Electronics FPCs: Low-to-mid-range devices like feature phones, portable audio players, and home appliance control panels use HASL-finished FPCs. These applications rely on standard components and high-volume production .

Industrial Control FPCs: FPCs in control panels, sensors, and basic automation equipment benefit from HASL’s oxidation resistance and solderability, ensuring reliable operation in industrial environments.

Non-Critical Automotive FPCs: Infotainment systems, interior lighting controls, and basic sensors use HASL FPCs, where cost and compatibility with standard soldering take precedence over safety-critical performance .

LED Driver FPCs: High-volume LED modules and driver circuits adopt HASL for its cost-effectiveness and compatibility with standard LEDs, supporting mass production in lighting applications .

Basic Power Electronics FPCs: Simple power supplies and rectifiers use HASL FPCs to handle high-current solder joints, though advanced power FPCs require alternative finishes for thermal management.

5. Critical Processing Tips for HASL on FPCs

To ensure quality in HASL-finished FPCs, manufacturers must adhere to strict controls—practices enforced by Huaruixin Electronics:

Select FPC-Specific Solder Alloys: Choose lead-free alloys (e.g., Sn-Ag-Cu) for RoHS compliance, matching the alloy’s melting point to the FPC’s Tg value (e.g., PI substrates with Tg >180°C). Avoid tin-lead alloys for global markets .

Precise Thermal Control for FPCs: Limit immersion time to 3–5 seconds and monitor bath temperature (220–230°C for tin-lead, 240–260°C for lead-free) to prevent PI substrate warping. Use pre-heating to reduce thermal shock .

Optimize Hot Air Knife Settings: Adjust air pressure (0.2–0.5 MPa) and temperature to match FPC thickness. Align knives parallel to the FPC surface to ensure uniform solder removal, especially near coverlay edges .

Thorough FPC Pre-Treatment: Clean FPC surfaces with chemical solutions to remove flux residues, oil, or dust before HASL. This ensures strong solder adhesion to copper pads, critical for flexible circuits .

FPC-Specific Post-Inspection: Use laser profilometers to verify solder thickness (5–15 μm) and check for bridging or uneven coating. Ensure compliance with IPC-A-610 and IPC-6012 standards for FPC quality .

Leverage Certified Quality Systems: Operate under ISO 9001:2015 and CNAS-accredited processes (like Huaruixin) to ensure traceability and consistency in FPC HASL processing .

6. Partner with Huaruixin for HASL-Finished FPCs

Shenzhen Huaruixin Electronics Co., Ltd. is a global leader in FPC, PCB, and rigid-flex board ODM/OEM manufacturing, specializing in HASL and advanced surface finishing. Our state-of-the-art facilities and IAF-accredited quality system ensure RoHS-compliant, high-quality FPCs tailored to your needs—whether for consumer electronics, industrial controls, or automotive applications.

Need cost-effective HASL-finished FPCs or expert advice on surface finishing? Contact us today:

Website: Visit www.hrxfpc.com for FPC technical resources and manufacturing capabilities.

Email: Send inquiries to sales@hrxfpc.com for personalized support and project quotes.

Let Huaruixin’s FPC expertise elevate your next electronic product with reliable, cost-effective surface finishing solutions.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP