Search

Green Energy PCB: Characteristics, Differences, Manufacturing Tips & Wide Applications

- Dec 24,2025

-

Share

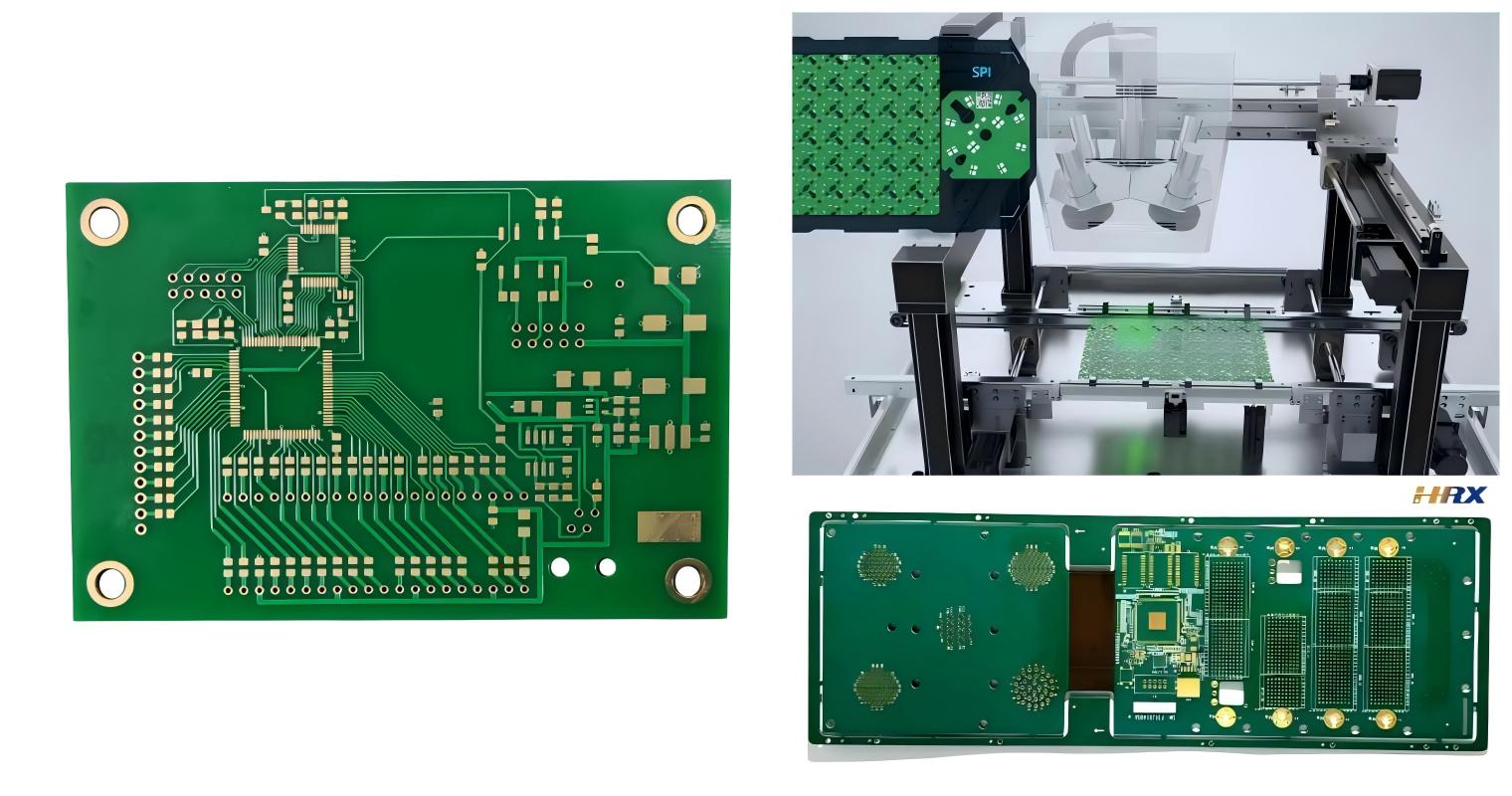

Amid the global drive for carbon neutrality and sustainable development, the green energy industry leads the new energy revolution. As a critical component in green energy devices, Green Energy PCB (Printed Circuit Board) ensures energy system efficiency, reliability, and environmental friendliness. Shenzhen Huaruixin Electronics Co., Ltd., a global ODM/OEM manufacturer specializing in FPC (Flexible Printed Circuit), PCB, and rigid-flex boards, has extensive experience in green energy PCB production. This blog explores its characteristics, differences from standard PCBs, key manufacturing considerations, problem avoidance strategies, and wide applications, integrating Huaruixin Electronics' professional insights and practical cases.

Key Characteristics of Green Energy PCB

Green Energy PCB is engineered to meet renewable energy sector requirements, with distinct properties distinguishing it from conventional PCBs:

- High Environmental Compatibility: Green Energy PCB complies with RoHS, REACH, and other international environmental standards, free from lead, mercury, cadmium, and hexavalent chromium. Huaruixin Electronics adopts green materials (lead-free solder masks, halogen-free substrates like FR-4, eco-friendly plating) to ensure a low-carbon lifecycle.

- Superior Thermal Stability: Green energy devices (solar inverters, wind converters, energy storage systems) generate significant heat. Green Energy PCB withstands high temperatures (≥125°C) using high-Tg substrates (Tg ≥ 170°C) to resist thermal deformation. For example, Huaruixin's high-Tg halogen-free PCB for solar inverters ensured stable performance in desert solar power plants.

- Excellent Electrical Reliability: Green energy applications involve high voltage, current, and frequency, requiring Green Energy PCB to have low dielectric loss (Dk), low water absorption, and high breakdown voltage. Huaruixin optimizes layout and selects high-performance materials to minimize interference. Its wind energy converter PCB achieved a breakdown voltage over 20kV, meeting wind power requirements.

- Enhanced Mechanical Durability: Green energy devices are often installed in harsh outdoor environments (wind farms, solar fields, coastal areas). Green Energy PCB has robust mechanical properties (tensile strength, impact resistance, corrosion resistance). Huaruixin uses advanced surface treatments (ENIG, OSP) to enhance corrosion resistance and ensure long-term reliability.

Differences Between Green Energy PCB and Standard PCB

While sharing the basic structure of standard PCB (substrate, copper foil, solder mask, etc.), Green Energy PCB differs significantly in material selection, performance requirements, and application scenarios:

- Environmental Requirements: Green Energy PCB strictly complies with RoHS, REACH, halogen-free and lead-free standards; Standard PCB meets basic requirements, with some low-end products containing lead or halogens.

- Thermal Performance: Green Energy PCB uses high-Tg substrates (Tg ≥ 170°C) for high-temperature resistance (125°C+); Standard PCB uses general Tg substrates (Tg ≈ 130-150°C) for normal temperatures (≤ 85°C).

- Electrical Performance: Green Energy PCB adapts to high voltage/current/frequency with low dielectric loss and high breakdown voltage; Standard PCB has basic performance for low-voltage, low-frequency consumer electronics.

- Environmental Adaptability: Green Energy PCB resists vibration, salt spray, UV and humidity for outdoor use; Standard PCB is for indoor consumer electronics with poor environmental adaptability.

- Manufacturing Standards: Green Energy PCB follows high-precision industrial/automotive-grade standards; Standard PCB meets general consumer electronics standards.

Huaruixin notes these differences require targeted manufacturing adjustments, such as stricter material inspection (halogen content, lead-free verification) and precise process control (controlled impedance, thermal management).

Key Manufacturing Details of Green Energy PCB & Problem Avoidance Strategies

Green Energy PCB production involves complex processes; oversight affects performance and reliability. Based on rich experience, Huaruixin summarizes key links and problem avoidance measures:

1. Material Selection and Inspection

Key Details: Substrate, solder mask, and plating quality directly determine performance. Non-environmentally friendly or low-quality materials cause non-compliance and shortened lifespan.

Problem Avoidance: Huaruixin implements strict supplier audits and incoming material testing (XRF for halogen content, lead-free verification, Tg testing). For example, halogen-free substrates are tested to ensure total halogen content <900ppm (IPC-4101), with non-compliant materials rejected.

2. Controlled Impedance Design and Fabrication

Key Details: Precise impedance matching is critical for green energy devices; improper control causes signal distortion and reduced conversion efficiency.

Problem Avoidance: Huaruixin uses EDA software for impedance simulation during design, controls copper thickness, dielectric constant, and trace spacing during fabrication, and inspects with professional testers (error ±5%). Its photovoltaic inverter PCB reduced signal loss, improving efficiency by 2%.

3. Thermal Management Process

Key Details: Poor heat dissipation causes thermal accumulation, component failure, and reduced reliability. Thermal management (vias, thermal pads, layout) is crucial.

Problem Avoidance: Huaruixin optimizes layout, adds thermal vias/pads, and controls soldering temperature. Its wind turbine converter PCB (dense thermal via array) reduced surface temperature by 15°C, enhancing reliability.

4. Surface Treatment and Corrosion Resistance Enhancement

Key Details: Outdoor Green Energy PCB is prone to corrosion; improper surface treatment causes copper oxidation and reduced conductivity.

Problem Avoidance: Huaruixin selects surface treatments (ENIG for coastal areas, OSP for dry inland) and conducts salt spray (ASTM B117) and humidity (85°C/85% RH, 1000h) tests to verify corrosion resistance.

5. Quality Control and Reliability Testing

Key Details: Green Energy PCB is used in critical systems; defects cause safety accidents and losses. Comprehensive quality control and reliability testing are essential.

Problem Avoidance: Huaruixin implements full-process quality control, including electrical, mechanical, environmental, and reliability tests. For example, its energy storage battery FPC undergoes 10,000 bending cycles (radius 1mm) to withstand vibration and deformation.

Wide-Ranging Applications of Green Energy PCB

With excellent environmental performance, thermal stability, and reliability, Green Energy PCB is widely used in green energy fields. Huaruixin has provided customized solutions for global customers in these areas:

1. Solar Energy Industry

Green Energy PCB is core to solar inverters, charge controllers, and PV modules. Huaruixin's high-Tg halogen-free PCB for solar inverters is adopted by major companies, operating stably in extreme temperature environments with a service life exceeding 25 years.

2. Wind Energy Industry

In wind turbines, Green Energy PCB is used in converters, pitch, and yaw control systems. Huaruixin's rigid-flex PCB for pitch control integrates FPC flexibility and PCB rigidity, reducing connectors and improving reliability. It has passed IEC 61400 certification for onshore/offshore wind farms.

3. Energy Storage Industry

Energy storage systems rely on Green Energy PCB for BMS, PCS, and EMS. Huaruixin's high-precision BMS FPC is small, lightweight, and flexible, fitting narrow battery pack spaces with excellent thermal stability and overcurrent protection.

4. Electric Vehicle (EV) Industry

EVs use Green Energy PCB in OBC, DC-DC converters, and motor controllers. Huaruixin's high-voltage OBC PCB (breakdown voltage >30kV) meets high-power charging requirements and complies with IATF 16949 standards.

5. Other Renewable Energy Fields

Green Energy PCB is also used in hydropower control, geothermal, and tidal energy devices. Huaruixin provides customized solutions based on specific field requirements to enhance customer competitiveness.

Conclusion & Call to Action

Green Energy PCB, with its environmental friendliness, thermal stability, electrical reliability, and mechanical durability, is essential for the global green energy revolution. Its differences from standard PCB require specialized manufacturing and strict quality control. As a global leader in FPC, PCB, and rigid-flex board manufacturing, Huaruixin provides high-quality Green Energy PCB ODM/OEM solutions worldwide, with successful cases in solar, wind, energy storage, and EV fields.

If you have Green Energy PCB project requirements, Huaruixin is your professional partner. Feel free to contact us anytime. For more industry knowledge, visit www.hrxfpc.com or email sales@hrxfpc.com for exchange and guidance.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP