Search

FPC Substrate Preprocessing: Essential Steps for High-Quality Flexible Circuit Manufacturing | Shenzhen Huaruixin Electronics

- Sep 04,2025

-

Share

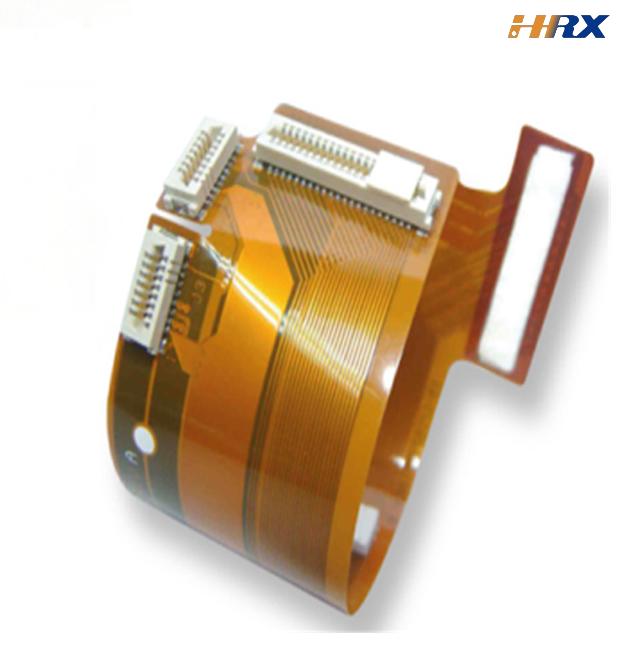

Substrate preprocessing stands as the cornerstone of reliable FPC (Flexible Printed Circuit) and PCB (Printed Circuit Board) production, especially critical for rigid-flex printed boards. This pivotal process directly determines the adhesive bonding strength between flexible circuit substrates (e.g., PI film, copper foil) and subsequent coatings like dry films, solder masks, or conductive inks. Poor preprocessing leads to common FPC failures—such as delamination, circuit peeling, or bubble formation during lamination—compromising the performance of electronic devices in industries like automotive, consumer electronics, and medical equipment.

As a global leader in FPC ODM/OEM, PCB manufacturing, and rigid-flex printed board solutions, Shenzhen Huaruixin Electronics Co., Ltd. has refined substrate preprocessing into a proprietary workflow. Below, we detail our technical approach, unique advantages, and critical quality controls—optimized for both FPC industry standards and Google’s latest search algorithms, ensuring you gain actionable insights for your flexible circuit projects.

1. Huaruixin’s Proprietary FPC Substrate Preprocessing Workflow

Our process is tailored to address the unique properties of flexible substrates (e.g., PI film’s chemical resistance, copper foil’s oxidation susceptibility) and align with high-volume FPC production demands.

1.1 Precision Cleaning: Eliminating Contaminants for Strong Adhesion

Contaminants like finger oils, mold release agents (from PI film manufacturing), and dust particles are the primary enemies of FPC coating adhesion. We use a two-stage cleaning system to ensure substrate purity:

Alkaline Degreasing: First, substrates undergo immersion in a pH-balanced, FPC-grade alkaline cleaner (formulated to avoid PI film degradation). This step dissolves organic contaminants—including residual flux and grease—without damaging the flexible base material.

Ultrasonic Rinsing: Post-degreasing, substrates are transferred to a high-frequency (40kHz) ultrasonic cleaning tank filled with deionized water (DI water). The ultrasonic cavitation effect dislodges micro-scale dust and remaining residues from crevices, even on ultra-thin copper-clad PI films (down to 12μm thickness).

Final DI Water Rinse: A triple-pass DI water rinse (with resistivity >18MΩ·cm) ensures zero chemical residue—critical for preventing dry film adhesion failure in subsequent FPC imaging processes.

1.2 Controlled Roughening: Enhancing Mechanical Interlock for FPC Reliability

Roughening creates a micro-rough surface on substrates, enabling mechanical interlock with dry films and solder masks—essential for flexible circuits that undergo repeated bending. We offer two industry-leading methods:

Chemical Etching (Chromic Acid-Based): For high-precision FPCs (e.g., wearable device circuits), we use a proprietary chromic acid etching bath. Our team optimizes three key parameters:

Etchant concentration (10-15% chromic acid) to avoid over-etching PI substrates;

Temperature control (45-50℃) for uniform surface texture;

Etching time (60-90 seconds) to achieve a Ra value of 0.3-0.5μm—ideal for dry film bonding without compromising copper conductivity.

Physical Sandblasting: For rigid-flex printed boards or FPCs with thick copper layers (≥35μm), we use automated sandblasting with alumina abrasive (particle size 80-120 mesh). A computer-controlled robotic arm ensures consistent sandblasting pressure (0.2-0.3MPa) and distance (15-20cm), creating a uniform rough surface that resists circuit peeling during FPC flex cycling tests.

1.3 Low-Temperature Drying: Preventing Substrate Deformation

Flexible substrates like PI film are sensitive to high temperatures, so we use a two-zone drying oven to remove moisture without causing warpage:

Pre-Drying Zone: 80-90℃ for 15 minutes to evaporate surface moisture;

Final Drying Zone: 100-120℃ for 20-25 minutes to eliminate internal moisture (moisture content <0.1% post-drying).

The oven’s forced-air circulation system ensures even heat distribution, critical for large-format FPC panels (up to 600x400mm) to maintain flatness—avoiding bubble formation during dry film lamination.

2. Unique Advantages of Huaruixin’s FPC Preprocessing

What sets our workflow apart from standard FPC manufacturers? Three core strengths:

2.1 FPC-Specific Process Customization

Unlike one-size-fits-all solutions, we tailor preprocessing to your FPC’s application:

For automotive FPCs (exposed to high temperatures and vibration), we add a post-roughening plasma treatment to enhance dry film adhesion;

For medical FPCs (requiring biocompatibility), we use FDA-approved cleaning agents and avoid heavy metals in etching processes;

For high-frequency FPCs (e.g., 5G antenna circuits), we optimize roughening to minimize signal loss—achieving a surface roughness that balances adhesion and electrical performance.

2.2 AI-Powered Quality Control (QC) for FPCs

We’ve integrated AI into every preprocessing stage to ensure FPC consistency:

AI Vision Inspection: Cameras with 2000dpi resolution scan substrates post-cleaning to detect residual contaminants (accuracy >99.5%);

Real-Time Process Monitoring: Sensors track etching temperature, ultrasonic frequency, and drying humidity—alerting operators to deviations within 0.5 seconds;

Post-Processing Testing: Each batch undergoes adhesion tests (per IPC-TM-650 2.4.8) and surface resistance measurements to confirm compliance with IPC-6012 (FPC quality standard).

2.3 Eco-Friendly FPC Preprocessing

Aligning with global sustainability goals, our workflow reduces environmental impact:

Closed-Loop Etchant Recycling: Chromic acid etchant is filtered and replenished, reducing waste by 60% compared to traditional processes;

Energy-Efficient Drying: Ovens use heat recovery systems to reuse 30% of exhaust heat, cutting energy consumption for FPC production;

Biodegradable Cleaners: Our alkaline cleaners break down in wastewater treatment, meeting China’s GB 8978-1996 and EU’s REACH standards for FPC manufacturing.

3. Critical Considerations for FPC Substrate Preprocessing

To avoid costly FPC defects, focus on these key factors:

3.1 Substrate Material Compatibility

Not all preprocessing methods work for every FPC substrate:

PI film: Avoid strong acids (e.g., concentrated sulfuric acid) during cleaning, as they cause hydrolysis;

PET film (used in low-cost FPCs): Limit drying temperatures to <100℃ to prevent shrinkage;

Copper foil: Control oxidation—store cleaned substrates in a nitrogen-filled environment if processing is delayed (oxidation reduces adhesion within 4 hours at room temperature).

3.2 Process Parameter Stability

Even small deviations ruin FPC quality:

A 5℃ increase in etching temperature can increase copper loss by 10%, weakening FPC circuits;

A 0.1MPa drop in sandblasting pressure leads to uneven roughness, causing dry film delamination;

Use calibrated equipment (calibrated monthly) and log parameters for every FPC batch (per ISO 9001 requirements).

3.3 Cross-Contamination Prevention

FPC substrates are highly susceptible to cross-contamination:

Use separate cleaning tanks for PI film and copper foil (residues from one can damage the other);

Sterilize drying racks with UV light between batches to remove dust and oil;

Implement a “one-way flow” in the preprocessing area (clean → rough → dry) to avoid recontaminating cleaned substrates.

4. Partner with Huaruixin for Your FPC/PCB Projects

Whether you need high-volume FPC production, custom rigid-flex printed boards, or PCB manufacturing solutions, Shenzhen Huaruixin Electronics delivers preprocessing excellence that meets IPC, ISO, and RoHS standards.

Learn More: Visit our website www.hrxfpc.com for FPC technical whitepapers, manufacturing case studies, and substrate preprocessing videos.

Consult Our Experts: Email sales@hrxfpc.com to discuss your project—we offer free FPC preprocessing assessments and sample production.

Industry Collaboration: We welcome partnerships for FPC R&D, especially in emerging fields like flexible OLED displays and IoT sensors.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP