Search

FPC Solutions for Battery & Energy Storage: Design, Production & Quality Control by Huaruixin

- Aug 18,2025

-

Share

As a leading ODM/OEM manufacturer specializing in Flexible Printed Circuit (FPC), Rigid-Flex PCB, and Printed Circuit Board (PCB) solutions, Shenzhen Huaruixin Electronics Co., Ltd. excels in end-to-end design, development, and large-scale production. With a strategic focus on FPC for battery systems and energy storage FPC applications, we leverage our expertise to replace traditional wire harnesses with high-performance flexible circuits, driving innovation across consumer electronics, new energy vehicles (NEVs), and industrial energy storage sectors.

Strategic Layout: FPC in Battery & Energy Storage Ecosystems

Our FPC layout strategy is engineered to address the unique demands of battery and energy storage markets, where flexibility, reliability, and space efficiency are paramount.

1. Battery Systems: Redefining Connectivity with FPC

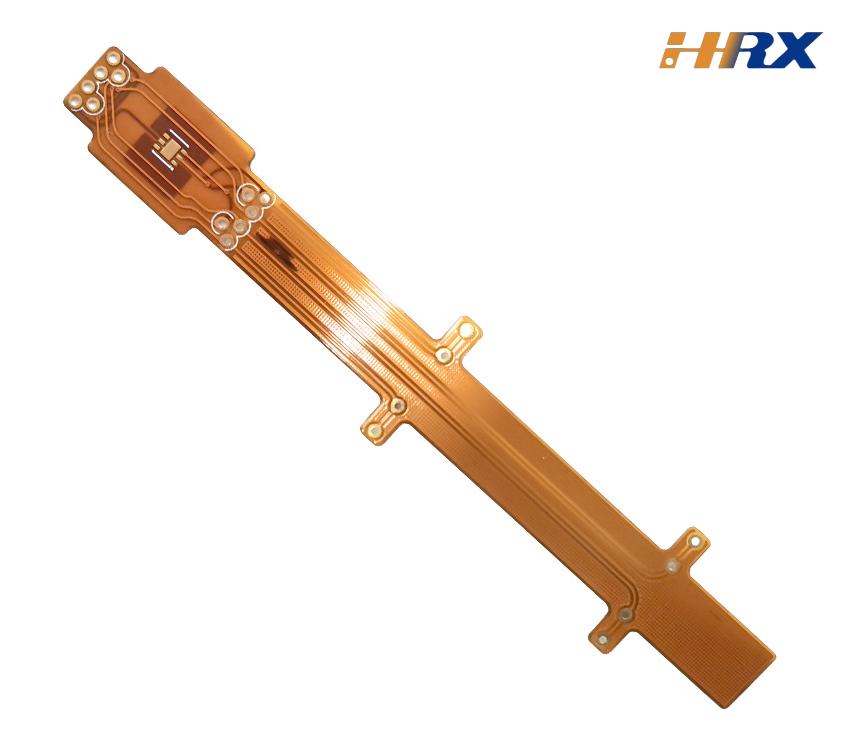

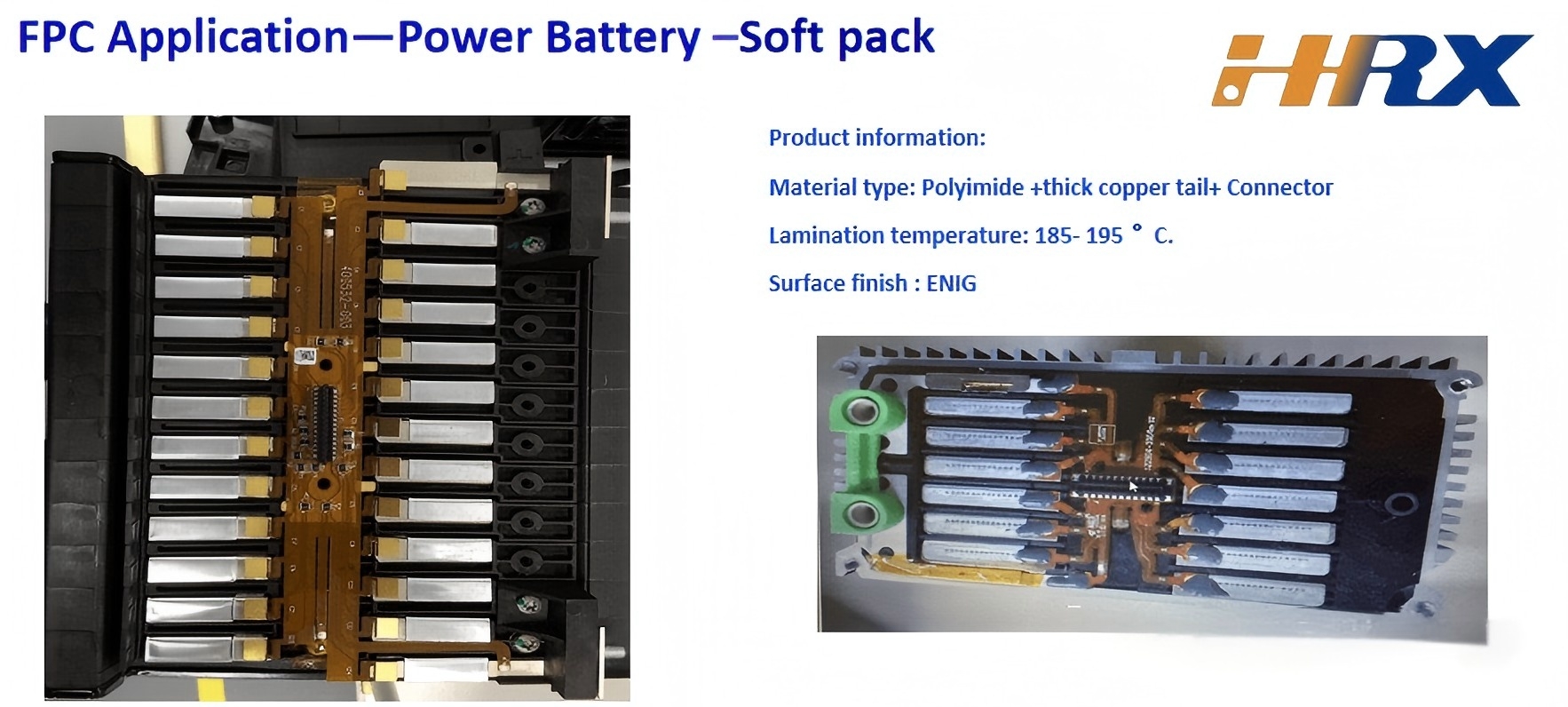

In consumer electronics batteries and NEV battery packs, traditional wire harnesses often limit design flexibility and increase failure risks. Our custom FPC solutions overcome these challenges through:

High-density interconnect (HDI) FPC designs to optimize signal transmission between battery management systems (BMS) and cells, reducing crosstalk and improving data accuracy.

Flexible circuit miniaturization using advanced patterning techniques (35μm line/space) to fit compact battery enclosures, maximizing energy density in devices like smartphones and EV battery modules.

High-current FPC configurations with thick copper layers (2oz–4oz) and reinforced stiffeners, ensuring stable power distribution in high-voltage battery systems.

2. Energy Storage Sector: FPC for Long-Term Reliability

As global demand for energy storage systems (ESS) surges, our FPC solutions are tailored to meet the sector’s rigorous requirements:

High-temperature resistant FPC using polyimide (PI) substrates and silicone adhesives, withstanding operating temperatures up to 150°C in ESS cabinets.

Vibration-resistant flexible circuits designed with stress-relief bends and reinforced termination points, ensuring durability in industrial storage environments.

Custom FPC for battery energy storage (BESS) with flame-retardant materials (UL 94 V-0 rated), complying with safety standards like IEC 62133.

Design, Production & Quality Control: Engineering Excellence

At Huaruixin, FPC quality is built into every stage of the process, from design to delivery.

1. FPC Design: Precision Engineering for Performance

Our design team focuses on application-specific optimization:

Material science integration: Selecting low-Dk PI films for signal integrity, high-conductivity electrolytic copper for current-carrying capacity, and halogen-free laminates for eco-friendly requirements.

DFM (Design for Manufacturability) principles: Using 3D simulation tools to validate flex-to-rigid transitions, bend radius compliance, and solder mask alignment, ensuring producibility at scale.

Compliance with standards: Adhering to IPC-2221 (Flexible Circuit Design) and IPC-6013 (Qualification and Performance Specification for Flexible Printed Boards) for consistent quality.

2. FPC Production: Advanced Manufacturing Capabilities

Our state-of-the-art manufacturing base ensures precision and scalability:

Laser Direct Imaging (LDI) for high-accuracy circuit patterning, achieving 25μm line/space resolution for HDI FPC.

Automated lamination systems for uniform bonding of copper layers and substrates, reducing delamination risks in high-heat applications.

Electroless nickel immersion gold (ENIG) and tin plating finishes to enhance solderability and corrosion resistance in battery environments.

3. Quality Control: Rigorous Testing for Reliability

We implement a multi-layered QC framework to ensure FPC performance:

Incoming Quality Control (IQC): Testing copper clad laminates (CCL) for thickness tolerance, dielectric strength, and thermal stability.

In-process inspection: Using Automated Optical Inspection (AOI) and X-ray inspection to detect defects like shorts, opens, and voids in inner layers.

Reliability testing: Conducting thermal shock tests (-55°C to 125°C, 1000 cycles), flex life testing (10,000+ bends), and moisture resistance tests (85°C/85% RH, 1000 hours) to validate long-term performance.

Key Considerations for FPC in Battery & Energy Storage Applications

To ensure FPC success in these critical sectors, focus on:

Material compatibility: Ensuring FPC substrates and adhesives resist electrolyte chemicals in batteries and ESS, preventing degradation over time.

Mechanical durability: Designing for repeated bending (in foldable devices) or static flexibility (in fixed battery packs) without compromising conductor integrity.

Thermal management: Incorporating thermal vias and heat-dissipating copper planes to prevent hotspots in high-power applications.

Regulatory compliance: Meeting automotive (ISO 26262) and energy storage (UL 94) standards to ensure safety and market access.

Partner with Huaruixin for Your FPC Needs

Whether you require custom FPC for battery packs, high-temperature flexible circuits for energy storage, or rigid-flex PCB solutions, Huaruixin Electronics delivers reliability and innovation. Our expertise in FPC design, advanced production capabilities, and strict quality control make us your trusted partner.

Ready to discuss your project?

Visit our website: www.hrxfpc.com for more FPC technical resources.

Email our team: sales@hrxfpc.com to consult on custom FPC solutions.

Let’s power the future of electronics with high-performance FPC technology.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP