Search

FPC Solder Mask & Coverlay Processing: Expert Solutions by Huaruixin Electronics (Top FPC Manufacturer China)

- Sep 12,2025

-

Share

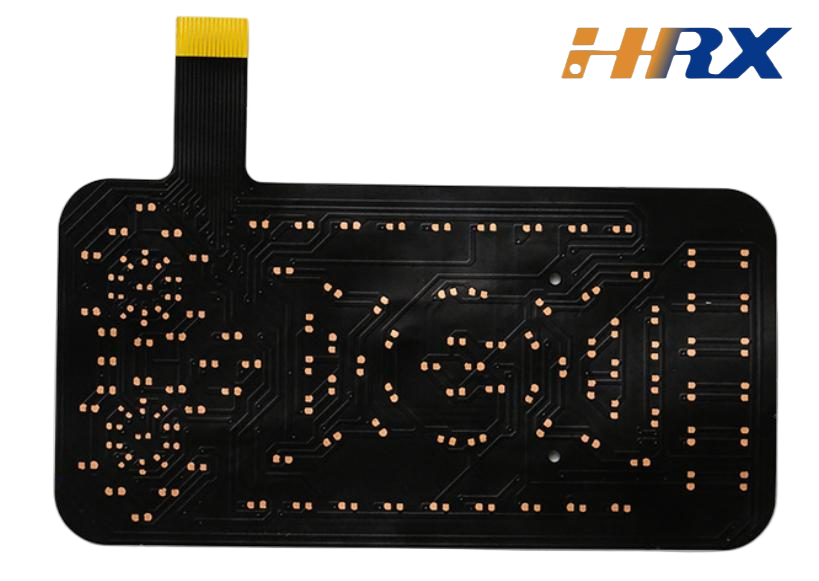

In the Flexible Printed Circuit (FPC) fabrication workflow, post-circuit protection—specifically solder mask application and coverlay lamination—stands as a make-or-break step for product reliability. Exposed copper traces on FPCs are prone to copper oxidation (which degrades electrical conductivity) and mechanical scratches (leading to circuit open/short circuits). To mitigate these risks, a robust protective layer is mandatory, leaving only solder pads (for SMT component soldering) and connector interfaces (for inter-board connectivity) uncovered.

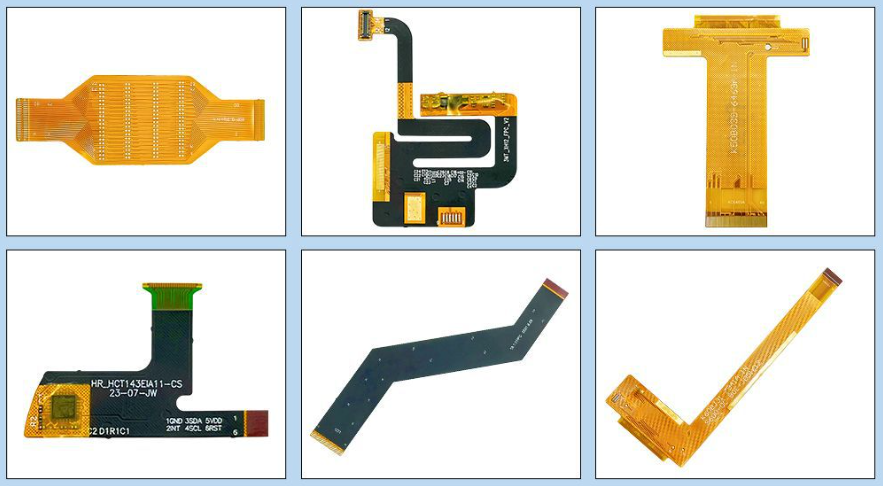

Shenzhen Huaruixin Electronics Co., Ltd. is a globally recognized ODM/OEM FPC manufacturer specializing in FPC, PCB, and Rigid-Flex PCB production. With in-house R&D capabilities and a large-scale manufacturing base, we deliver tailored FPC protection solutions to industries like consumer electronics, automotive electronics, medical devices, and industrial automation. Below, we detail our optimized solder mask printing and coverlay lamination processes, unique competitive advantages, and critical quality control measures—all designed to meet the highest standards of FPC performance and durability.

1. Huaruixin’s Tailored FPC Protection Solutions: Solder Mask vs. Coverlay

At Huaruixin, we avoid one-size-fits-all approaches. Instead, we select the optimal protection method based on FPC circuit complexity, cost constraints, and end-use requirements—ensuring clients get the best value without compromising quality.

1.1 Coverlay Lamination: For High-Performance & Complex FPCs

For high-density FPCs (e.g., 5G device antennas, automotive ADAS sensors) or applications demanding extreme flexibility and environmental resistance, we prioritize polyimide coverlay lamination. Our process is optimized for:

High-Grade Coverlay Materials: We source RoHS/UL/IPC-compliant coverlay (e.g., PI-based with acrylic/epoxy adhesives) that offers superior oxidation resistance, scratch protection, and flex fatigue resistance (withstanding 100,000+ bending cycles at 1mm radius).

Automated CCD Alignment Lamination: Our advanced lamination machines use CCD vision systems for ±0.05mm alignment accuracy—eliminating manual errors that cause coverlay misalignment (blocking pads/interfaces).

Controlled Thermocompression Parameters: We customize pressure (1.2-1.5MPa) and temperature (130-150℃) based on substrate thickness (0.1-0.3mm) and coverlay type, ensuring bubble-free adhesion (a key cause of coverlay delamination in high-temperature environments).

1.2 Solder Mask Printing: For Cost-Effective & Simple FPCs

For low-complexity FPCs (e.g., wearable device cables, basic interconnects) where cost optimization is critical, our liquid solder mask printing (a PCB-style "green oil" alternative to coverlay) delivers reliable protection. Our standardized workflow includes:

High-Mesh Screen Printing: We use 350-400 mesh stainless steel screens for uniform solder mask thickness (15-25μm), with custom stencils to precisely avoid pads/interfaces (preventing solder mask bridging).

Humidity-Controlled Pre-Baking: FPCs are baked at 75-80℃ for 15-20 minutes in humidity-controlled ovens (40-50% RH)—critical for solvent evaporation and preventing solder mask sagging.

UV Exposure with High-OD Photomasks: We use polyester photomasks (optical density ≥4.0) to expose solder mask areas, with a UV machine (365nm wavelength) that maintains consistent light intensity (800-1000mJ/cm²) for full curing (avoiding under-cured solder mask).

Alkaline Developing & High-Temp Curing: Uncured solder mask is removed with pH 10.8-11.2 alkaline solution (spray pressure 0.25MPa), followed by 160-180℃ curing for 70-80 minutes—resulting in a hard, scratch-resistant layer (≥2H pencil hardness).

2. Huaruixin’s Unique Advantages: Why Choose Us for FPC Protection?

As a top FPC manufacturer in China, Huaruixin stands out with capabilities that address industry pain points—from design to delivery.

2.1 Design-Manufacturing Synergy for FPC Optimization

Our in-house R&D team collaborates with production to optimize FPC layout (e.g., pad size, interface spacing) and select the right protection method early—avoiding rework caused by poor design (e.g., pad undercutting from incorrect solder mask exposure). This reduces lead times by 20% compared to competitors.

2.2 Strict IPC-6012 Compliance & Multi-Stage QC

We adhere to IPC-6012 (FPC performance standards) with a 5-step QC process:

Incoming Material Test: Verify coverlay/solder mask for adhesion strength (≥1.5N/mm) and chemical resistance (to solvents like isopropyl alcohol).

In-Process AOI Inspection: Use automated optical inspection to detect solder mask defects (e.g., pinholes, missing areas) and coverlay misalignment.

Post-Curing Testing: Conduct thermal shock tests (-40℃ to 125℃, 100 cycles) and humidity tests (85% RH at 85℃, 500 hours) to validate protection durability.

Mechanical Validation: Perform scratch tests (500g load) and bending tests to ensure no protection layer damage.

Final Electrical Testing: Check for insulation resistance (≥10¹²Ω) between traces to confirm no solder mask/coverlay flaws affect performance.

2.3 Custom Solutions for Industry-Specific FPCs

We specialize in custom FPC protection for demanding sectors:

Automotive FPC: Use high-temperature solder mask (curing up to 200℃) and flame-retardant coverlay (UL94 V-0) for engine-compartment FPCs.

Medical FPC: Offer biocompatible coverlay (ISO 10993 compliant) and low-outgassing solder mask for wearable monitors/surgical tools.

High-Frequency FPC: Select low-Dk coverlay (Dk ≤3.0 at 10GHz) and solder mask to minimize signal loss for 5G/6G devices.

2.4 Scalable Production: From Prototypes to Mass Orders

With 25+ lamination lines and 18 solder mask printing stations, we handle:

FPC Prototypes: 10-100 units in 3-5 days (ideal for startups/design firms).

Mass Production: 100,000+ units/month with 7-10 day lead times (meets consumer electronics/automotive volume needs).

3. Critical Considerations for FPC Solder Mask & Coverlay Processing

Even with advanced technology, ignoring these factors leads to costly defects. Huaruixin prioritizes:

3.1 Pad Exposure Precision

Risk: Overly small pad exposure causes solder joint failure; overly large exposure leaves copper vulnerable to oxidation.

Solution: AOI verifies pad exposure size (tolerance ±0.03mm) per IPC standards—ensuring optimal solderability.

3.2 Substrate Cleanliness Before Processing

Risk: Oil/dust on FPC substrates causes poor coverlay/solder mask adhesion (leading to delamination).

Solution: We use plasma cleaning (O₂ plasma, 500W) to remove contaminants—boosting adhesion strength by 30%.

3.3 Compatibility with Post-Processing

Risk: Solder mask/coverlay may degrade during reflow soldering (260℃ peak) or conformal coating.

Solution: We test protection layers for reflow resistance (3 cycles at 260℃) and compatibility with conformal coatings (e.g., acrylic, silicone).

3.4 Flexibility Retention

Risk: Over-cured solder mask makes FPCs brittle (cracking during bending).

Solution: We control curing time/temperature and use flexible materials—ensuring FPCs retain ≥80% flexibility after processing.

4. Partner with Huaruixin: Your Trusted FPC Manufacturer China

If you need custom FPCs with reliable solder mask/coverlay protection—whether for consumer electronics, automotive, or medical applications—Huaruixin delivers quality, speed, and customization.

Explore Our Expertise: Visit www.hrxfpc.com to learn about our FPC manufacturing capabilities, case studies, and industry certifications (ISO 9001).

Get a Quote or Consultation: Email sales@hrxfpc.com with your project specs (e.g., FPC size, circuit complexity, end-use). Our team responds within 24 hours to provide tailored solutions.

As a leading FPC ODM/OEM provider, Huaruixin is committed to helping you build durable, high-performance products. Let’s innovate together!

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP