Search

FPC Post-Processing: Drilling, Reinforcement & Surface Treatment for High-Reliability Flexible Circuits

- Sep 17,2025

-

Share

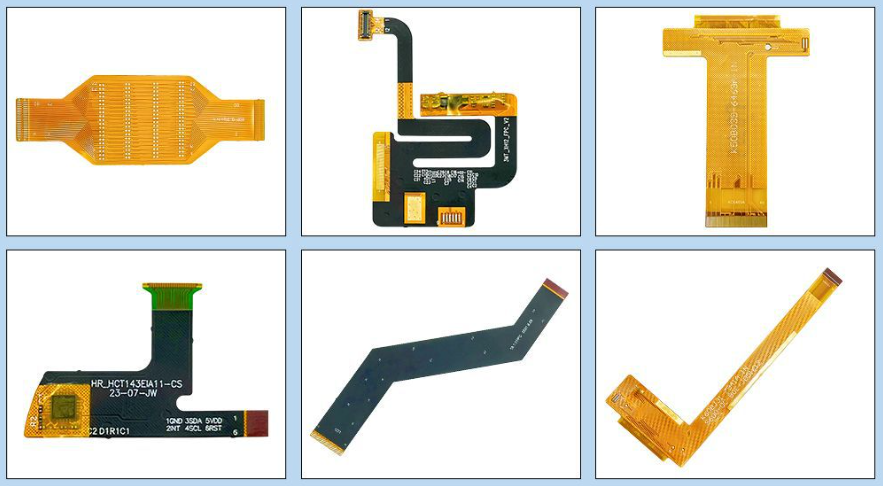

Flexible Printed Circuits (FPCs) are the backbone of modern electronics miniaturization, powering devices from wearable tech to automotive infotainment systems. However, FPC reliability hinges entirely on post-processing—specifically FPC reinforcement, precision FPC drilling, and FPC surface treatment—steps that transform raw flexible substrates into durable, performance-ready components.

As a leading global FPC ODM/OEM manufacturer and provider of PCB & Rigid-Flex Printed Board solutions, Shenzhen Huaruixin Electronics Co., Ltd. masters these critical post-processing stages with advanced technology, IPC-2223 compliance, and customized workflows. This blog breaks down Huaruixin’s industry-leading approach to FPC post-processing, its unique competitive advantages, and key considerations for optimizing FPC fabrication—all optimized to help you understand how to achieve long-lasting, high-performance flexible circuits.

1. Huaruixin’s Advanced FPC Post-Processing Workflow

Post-processing is where FPCs gain mechanical strength, electrical connectivity, and environmental resilience. Huaruixin’s process is tailored to meet diverse industry needs (consumer electronics, medical devices, automotive) while aligning with global quality standards. Below is a detailed breakdown:

1.1 FPC Reinforcement: Strengthening Critical Stress Points

Raw FPCs excel at flexibility but require reinforcement to withstand mechanical stress in high-use areas (e.g., connector ports, component pads). Huaruixin’s FPC reinforcement service focuses on durability without compromising flexibility:

Material Selection: Uses application-specific reinforcement materials, including:

Polyimide (PI) Film: For high-temperature resistance (-269°C to 400°C) and compatibility with flexible designs.

FR4 Epoxy: Ideal for rigid sections needing PCB-like stability (e.g., sensor mounting).

Stainless Steel Sheets: For heavy-duty applications (automotive, industrial) requiring impact resistance.

Precision Lamination: Employs computer-controlled press machines with variable temperature (120-180°C) and pressure (20-50 kg/cm²) to ensure bubble-free adhesion. Post-lamination, 100% peel strength testing (per IPC-TM-650 2.4.9) verifies bond integrity.

Customization: Reinforcement patterns are CAD-designed to match customer PCB layouts, avoiding interference with traces or vias.

1.2 High-Precision FPC Drilling: Enabling Interlayer Conduction & Assembly

Drilling is a make-or-break step for double-layer FPCs (needing interlayer connectivity) or FPCs requiring precise assembly. Huaruixin’s FPC drilling service combines cutting-edge equipment with strict quality control to achieve micron-level accuracy:

1.2.1 Equipment: Matching Drill Type to Aperture Requirements

UV Laser Drilling Machines: For ultra-small apertures (down to 0.1mm) critical for miniaturized FPCs (e.g., smartwatch PCBs). Key advantages:

Minimal heat-affected zone (HAZ <5μm) to protect thin FPC substrates (0.05-0.2mm thick).

Position accuracy of ±0.01mm, ensuring alignment with fine-pitch traces (50μm line/space).

High throughput (up to 10,000 holes per minute) for mass production.

CNC Mechanical Drilling Machines: For larger apertures (≥0.2mm) such as FPC positioning holes (0.5-2mm). Huaruixin uses carbide-tipped drills with automatic wear detection, reducing burrs to <10μm (per IPC-6012 Class 3 standards).

1.2.2 Drill Hole Types: Tailored to Electrical & Mechanical Needs

FPC Vias (Interlayer Conduction Holes):

Purpose: Connect upper and lower copper layers in multi-layer FPCs. Huaruixin’s process includes:

Desmearing: Plasma cleaning removes resin residue from hole walls to ensure copper adhesion.

Electroless Copper Plating: Deposits a 0.5-1μm copper seed layer for electrical conductivity.

Electrolytic Copper Plating: Builds copper thickness to 15-35μm (customizable for current-carrying needs).

FPC Positioning Holes:

Purpose: Enable precise alignment during SMT assembly or housing integration. Huaruixin controls dimensional tolerance to ±0.02mm, ensuring compatibility with automated assembly fixtures.

1.2.3 Post-Drilling Cleaning: Preventing Contamination

After drilling, Huaruixin uses high-pressure air cleaning (8-10 bar) to remove dust and debris from holes—critical for avoiding plating defects (e.g., voids) or electrical shorts. For medical/aerospace FPCs, an additional ultrasonic cleaning step (40kHz frequency) eliminates micro-residues, meeting strict industry hygiene standards.

1.3 FPC Surface Treatment: Enhancing Solderability & Corrosion Resistance

Surface treatment protects FPC copper layers from oxidation and improves solder joint reliability. Huaruixin offers custom FPC surface treatment options to match application environments:

Immersion Gold (ENIG): For high-reliability applications (medical devices, automotive ECUs). Provides:

2-5μm gold layer with nickel underplate (5-10μm) for corrosion resistance (passes 96-hour salt spray test per ASTM B117).

Low contact resistance (<50mΩ) for connector interfaces.

Immersion Tin: Cost-effective solution for consumer electronics (smartphones, tablets). Ensures lead-free solder compatibility (per RoHS 2.0) and shelf life of up to 6 months.

Organic Solderability Preservative (OSP): Ideal for FPCs with fine-pitch components (01005 chips). Forms a thin organic film (0.5-1μm) that dissolves during reflow soldering, leaving clean copper for bonding.

Hard Gold Plating: For wear-resistant applications (keypads, sliding contacts). Gold thickness (5-15μm) is controlled via X-ray fluorescence (XRF) testing.

2. Huaruixin’s Unique Advantages in FPC Post-Processing

What sets Huaruixin apart from other FPC manufacturers is its focus on integration, quality, and customization—key factors for businesses seeking reliable, scalable FPC solutions:

2.1 End-to-End ODM/OEM Capabilities

Unlike niche processors, Huaruixin offers full FPC fabrication services: from PCB design (DFM analysis to optimize post-processing) to prototyping, mass production, and testing. This integration ensures:

No disconnect between design and post-processing (e.g., drilling positions aligned with trace routing).

Faster time-to-market (prototyping turnaround: 3-5 days; mass production: 7-14 days).

2.2 AI-Powered Quality Control (QC)

Huaruixin leverages machine vision systems and AI to eliminate human error in post-processing:

AOI for Drilling: Automated optical inspection checks 100% of holes for position, aperture, and burrs—flagging defects in real time.

SPC for Surface Treatment: Statistical process control monitors plating thickness and uniformity, ensuring batch consistency (CPK ≥1.33).

Environmental Testing: FPCs undergo thermal cycling (-40°C to 125°C, 1000 cycles) and humidity testing (85% RH, 85°C, 500 hours) to validate reliability.

2.3 Globally Recognized Certifications

Huaruixin holds authoritative certifications to guarantee quality and compliance across industries:

GB/T19001-2016/ISO 9001:2015: Validates a robust quality management system (QMS) covering FPC design, production, and post-processing, ensuring consistent product performance.

IAF Accreditation: As an IAF (International Accreditation Forum) - recognized entity, Huaruixin’s quality certifications are accepted globally, facilitating cross-border cooperation with international clients.

CNAS Recognition: Certified by CNAS (China National Accreditation Service for Conformity Assessment), Huaruixin’s in-house testing reports meet international standards, reducing the need for third-party re-testing and accelerating project timelines.

2.4 Scalable Production Capacity

With a 10,000㎡ manufacturing base and 50+ post-processing machines (laser drills, lamination presses, plating lines), Huaruixin handles:

Small batches (10-100 units) for prototyping.

Large volumes (100,000+ units/month) for mass production.

3. Critical Considerations for FPC Post-Processing

Even with advanced technology, certain pitfalls can compromise FPC performance. Huaruixin addresses these proactively:

3.1 Material Compatibility

Risk: Incompatible materials (e.g., low-temperature reinforcement + high-temperature surface treatment) cause delamination.

Solution: Huaruixin’s material engineers conduct pre-production compatibility tests (thermal aging, adhesion strength) and provide DFM recommendations.

3.2 Drill Bit Wear Management

Risk: Worn drill bits cause oversized holes or burrs, leading to assembly failures.

Solution: CNC drills use automatic tool changers and wear sensors—bits are replaced after 5,000-10,000 holes (depending on material).

3.3 Plating Thickness Control

Risk: Insufficient copper plating in vias leads to high resistance or open circuits.

Solution: XRF testing measures plating thickness every 15 minutes during production, with adjustments made via PLC-controlled plating baths.

3.4 Environmental Compliance

Risk: Non-RoHS-compliant surface treatment (e.g., leaded solder) results in product rejection.

Solution: Huaruixin uses RoHS 2.0-compliant materials and treats waste water/plating chemicals per GB 21900-2008 (Chinese environmental standards).

4. Partner with Huaruixin for Your FPC Needs

Whether you need custom FPC drilling, reinforcement for flexible PCBs, or surface treatment for high-reliability applications, Huaruixin delivers solutions tailored to your requirements—backed by GB/T19001-2016/ISO 9001:2015, IAF, and CNAS certifications.

Get a Quote: For project inquiries, contact our sales team via sales@hrxfpc.com.

Learn More: Visit www.hrxfpc.com for FPC technical resources, case studies, and detailed certification documentation.

Technical Consultation: Our engineers are available to provide DFM advice, helping you optimize FPC design for post-processing efficiency and cost-effectiveness.

At Huaruixin, we don’t just process FPCs—we build long-term partnerships by delivering quality, reliability, and value that meets global standards.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP