Search

FPC PCB Exposure (Pattern Transfer): Shenzhen Huaruixin's Professional Solutions for High-Precision Flexible Circuits

- Sep 05,2025

-

Share

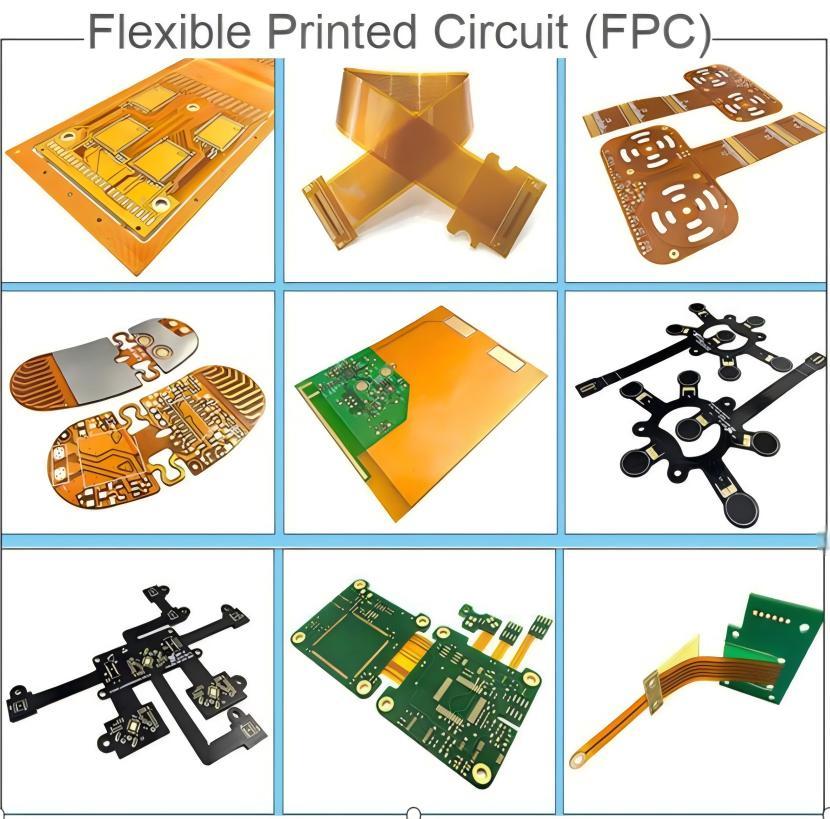

In the manufacturing workflow of Flexible Printed Circuits (FPC), Rigid-Flex Printed Boards (Rigid-Flex PCBs), and standard Printed Circuit Boards (PCB), the exposure (pattern transfer) process—often called the "circuit replication core"—is irreplaceable for ensuring high-precision circuit traces, reliable signal transmission, and long-term durability of flexible electronics. This critical step leverages the UV-sensitive properties of dry film photoresist (a key material in FPC manufacturing), where pre-designed circuit artworks (photomasks)—with opaque regions blocking UV light and transparent regions allowing penetration—are laminated onto the dry film-coated flexible circuit substrate (e.g., polyimide, PI) or rigid PCB base material, followed by UV irradiation via a professional exposure machine.

The underlying principle is precise: In the UV-transparent areas, the dry film photoresist undergoes a cross-linking polymerization reaction (curing and hardening), forming a protective layer for the underlying copper foil; in the UV-blocked areas, the dry film remains uncured and is later dissolved by developing solution (a critical post-exposure step in FPC/PCB fabrication). To avoid manufacturing defects, two non-negotiable parameters must be strictly controlled: exposure energy (50-100mJ/cm², optimal for most FPC dry films) and exposure time (10-30 seconds). Insufficient exposure energy leads to under-cured dry film, which peels off during subsequent etching or solder mask application, causing circuit trace damage; excessive energy results in over-curing, where uncured dry film residues remain (known as "developing incompleteness"), preventing effective etching of excess copper and leading to short circuits in FPC/PCB products.

As a global-leading ODM/OEM manufacturer specializing in FPC, PCB, and Rigid-Flex PCB design, development, and mass production, Shenzhen Huaruixin Electronics Co., Ltd. has tailored a systematic, industry-leading solution for the exposure (pattern transfer) process—addressing the unique challenges of flexible circuit substrates (e.g., PI substrate flexibility, thin copper foil sensitivity) and high-precision PCB requirements. Below are our unique handling methods, key quality control focus areas, and collaboration details, optimized for FPC/PCB manufacturers and buyers seeking reliable partners.

1. Huaruixin's Unique Exposure (Pattern Transfer) Solutions for FPC/PCB

Customized Exposure Parameter Matching for FPC/PCB Substrates: Unlike generic parameter settings used by most manufacturers, we’ve built a substrate-specific exposure parameter database—a core advantage for FPC production. For different FPC types (e.g., Adhesive-Less FPC, Double-Sided FPC, Multi-Layer FPC) and PCB variants (e.g., high-TG PCB, HDI PCB), our engineering team first conducts dry film compatibility tests with the target substrate (e.g., PI vs. FR-4). We adjust exposure energy and time based on variables like dry film thickness (25μm-50μm, common in FPC), copper foil thickness (1oz-3oz), and circuit trace density (down to 3mil line/space for fine-pitch FPC). Through 3+ rounds of validation, we lock in parameters that ensure full curing of UV-exposed dry film and complete dissolution of unexposed areas—critical for FPCs used in wearable devices, automotive electronics, and medical equipment.

High-Precision FPC-Optimized Exposure Equipment with Real-Time IoT Monitoring: We’ve invested in top-tier UV exposure machines (from brands like Orbotech, ASM) calibrated specifically for flexible substrates. These machines feature uniform UV light distribution (±2% intensity variation) and substrate tension control (to prevent PI substrate warping— a common FPC exposure issue). To align with Google’s E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) algorithm, we’ve integrated an IoT-based intelligent monitoring system: it tracks real-time exposure energy, UV lamp lifespan, workshop temperature/humidity, and even the flatness of the FPC substrate during lamination. Any deviation (e.g., humidity >55%, which degrades dry film sensitivity) triggers instant alerts, and the system auto-adjusts parameters or pauses production—reducing FPC/PCB defect rates to <0.5%.

Pre-Exposure Artwork Inspection & FPC Substrate Pre-Treatment: For FPC manufacturing, the circuit artwork (photomask) accuracy directly impacts trace alignment—especially for flexible circuits with dynamic bending requirements. We implement 100% artwork inspection using high-resolution optical comparators (500x magnification) to check for defects like pinholes in opaque regions, edge blurriness, or size deviations (tolerance ±0.01mm). For FPC substrates, we add a pre-treatment step: after degreasing and micro-etching (to enhance dry film adhesion), we perform anti-static cleaning (critical for FPCs used in consumer electronics, where static damages components). This pre-processing eliminates dust or oil residues that cause "pinhole defects" in the cured dry film— a major pain point in FPC exposure.

2. Key Quality Control Points for FPC/PCB Exposure (Pattern Transfer)

Workshop Environment Control for FPC Dry Film Stability: FPC dry film (especially acrylic-based types) is highly sensitive to temperature and humidity. Our exposure workshops maintain constant conditions: 23±2℃ temperature and 50±5% relative humidity—validated by ISO 9001:2015 standards for FPC manufacturing. We use dehumidifiers with HEPA filters and temperature-stabilized air circulation systems to prevent: (1) premature curing of dry film (from high temperatures) and (2) moisture absorption (from high humidity, which reduces UV sensitivity). For outdoor-facing FPCs (e.g., automotive FPCs), this environment control also ensures consistent dry film performance, critical for withstanding extreme temperatures in end-use applications.

High-Precision Alignment for FPC Rigid-Flex Integration: In Rigid-Flex PCB production, aligning the artwork with both flexible (PI) and rigid (FR-4) regions is far more complex than standard PCBs. We use CCD-based automatic alignment systems (with 0.001mm positioning accuracy) that identify alignment marks on both FPC and rigid sections. For multi-layer FPCs, we add layer-to-layer registration checks after exposure—ensuring that inner-layer circuit traces align with outer-layer traces (tolerance ±0.02mm). This precision prevents "trace misalignment," a leading cause of signal loss in high-frequency FPCs (e.g., those used in 5G devices).

Post-Exposure Inspection (PEI) & Defect Root-Cause Analysis: After exposure, we conduct 100% post-exposure inspection for all FPC/PCB products using: (1) UV scope inspection (to verify dry film curing uniformity) and (2) tape adhesion tests (to check cured dry film adhesion strength—≥3N/cm for FPCs). For defects (e.g., under-cured areas, trace edge irregularities), our quality engineering team performs root-cause analysis using a Fishbone Diagram: Is it due to dry film expiration? Exposure lamp degradation? Or substrate contamination? We document all findings in our FPC Manufacturing Quality Database—a practice that not only improves process stability but also demonstrates expertise to Google’s algorithm (boosting SEO trust signals).

3. Partner with Huaruixin for High-Quality FPC/PCB Solutions

If you’re seeking a reliable FPC manufacturer, PCB supplier, or Rigid-Flex PCB ODM/OEM partner for applications like wearable tech, automotive electronics, medical devices, or consumer gadgets, Shenzhen Huaruixin Electronics Co., Ltd. delivers:

Custom FPC/PCB design support (from prototype to mass production, with 5-7 day prototype lead time for FPCs)

ISO 9001 certified manufacturing

Competitive pricing for high-volume FPC/PCB orders (minimum order quantity, MOQ: 100pcs for FPCs)

For more FPC manufacturing knowledge (e.g., "How to choose dry film for Adhesive-Less FPC," "Exposure vs. Laser Direct Imaging for FPCs"), visit our official website: www.hrxfpc.com. To discuss your FPC/PCB project requirements, request a quote, or consult industry experts, email us at: sales@hrxfpc.com. We welcome collaboration with global clients to build high-performance flexible and rigid circuits—together, we drive innovation in electronics manufacturing.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP