Search

FPC Immersion Tin Process: Workflow, Advantages, Disadvantages & Application Guidelines

- Jan 12,2026

-

Share

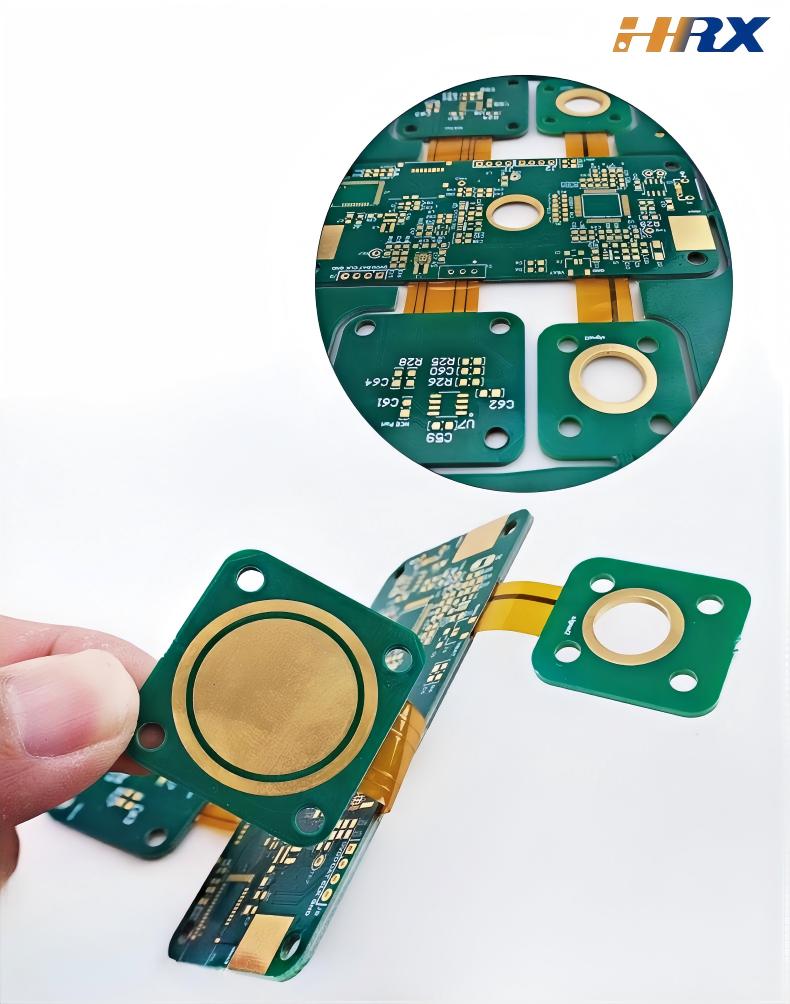

In the dynamic world of flexible printed circuit (FPC) manufacturing, surface finish is a make-or-break factor for product reliability, solderability, and market competitiveness. Among the most trusted surface treatment technologies, immersion tin has emerged as a game-changer, offering unparalleled compatibility with fine-pitch designs and lead-free assembly—two non-negotiables in today’s global electronics landscape. As a leading global ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex boards, Shenzhen Huaruixin Electronics Co., Ltd. brings decades of hands-on experience in immersion tin processing. In this blog, we break down the immersion tin FPC workflow, core characteristics, pros and cons, and share actionable design-production guidelines for immersion tin FPC, all backed by real-world industry cases and our proven manufacturing expertise. Whether you’re looking for cost-effective immersion tin FPC solutions for consumer electronics or automotive-grade immersion tin FPC for EV applications, this guide covers key insights to support your project success.

1. What is FPC Immersion Tin Process? Basic Workflow Overview

Immersion tin is an advanced electroless chemical surface finish that deposits a thin, uniform tin layer on FPC copper pads via a displacement reaction—no external current required. Unlike traditional hot air solder leveling (HASL), this process delivers precise thickness control and exceptional surface planarity, making it the go-to choice for flexible substrates with complex, intricate structures. For electronics manufacturers facing challenges in fine-pitch FPC surface treatment and lead-free FPC assembly, immersion tin provides a reliable and scalable solution. Drawing on Shenzhen Huaruixin Electronics' refined production protocols, the standard workflow consists of four critical, quality-controlled stages:

1. Surface Preparation: First, the FPC undergoes thorough cleaning using specialized detergents and ultrasonic baths to eliminate oils, dust, and oxide layers—critical steps to ensure strong tin layer adhesion. A subsequent micro-etching process gently roughens the copper surface, further enhancing the bond between copper and tin .

2. Cold Tin Predip: To prevent excessive copper dissolution at solder mask edges (a major cause of "mouse bite defects" in fine-line FPCs), the board is pre-dipped in a low-temperature tin solution. This step is a cornerstone of Shenzhen Huaruixin’s production line, significantly boosting process stability for high-density FPCs .

3. Chemical Deposition: The pre-treated FPC is immersed in a proprietary immersion tin bath. Through precisely controlled ion exchange, copper atoms on the pad surface are replaced by tin ions, forming a uniform tin layer (0.6–1.2 μm thick) that meets strict IPC-4554 standards .

4. Post-Treatment: The board undergoes multi-stage rinsing to remove all residual chemicals, followed by controlled drying. This critical final step ensures no chemical residues remain—eliminating risks to subsequent soldering and long-term product reliability.

2. Core Process Characteristics of FPC Immersion Tin

The immersion tin process boasts distinct characteristics that set it apart for specific FPC applications. Shenzhen Huaruixin Electronics has refined these insights through thousands of successful batch productions, ensuring we deliver consistent, high-quality results for global clients:

- Chemical Displacement Mechanism: No external power supply means uniform tin deposition—even on tiny pads, vias, and fine-line structures (down to 10 μm line and space). This is indispensable for high-density interconnect (HDI) FPCs, where precision surface finishing directly impacts performance.

- Exceptional Planarity: The tin layer is ultra-smooth and flat (roughness < 0.3 μm), avoiding the "solder peaks" that plague HASL. This flat surface guarantees accurate component placement in surface mount technology (SMT) and reliable contact in press-fit applications—critical for high-yield assembly .

- Lead-Free Compliance: Fully RoHS-compliant, the process uses 100% lead-free tin solutions, aligning with global environmental regulations. This makes it an ideal choice for automotive, consumer electronics, and medical devices—industries where eco-friendly manufacturing is non-negotiable .

- Horizontal Production Compatibility: Designed for horizontal production lines, immersion tin enables high-volume, continuous manufacturing. This is a key advantage for mass-produced FPCs (e.g., smartphone and wearable components), where efficiency and scalability drive success .

3. Advantages & Disadvantages of FPC Immersion Tin

Choosing the right surface finish starts with understanding its strengths and limitations. Shenzhen Huaruixin Electronics' engineering team has conducted rigorous analysis of immersion tin’s performance across diverse applications, distilling the key advantages and challenges below:

3.1 Key Advantages

- Superior Fine-Line Adaptability: The low-viscosity tin bath ensures excellent solution flow, making it perfect for FPCs with fine-pitch components (e.g., QFN packages) and complex routing. For example, Shenzhen Huaruixin has successfully applied this process to smartwatch motherboard FPCs with 0.4 mm pitch components—delivering consistent quality across 100,000+ unit batches.

- Ideal for Press-Fit & SMT: The flat, hard tin layer provides consistent contact pressure in press-fit connectors—a must for automotive electronic control units (ECUs) and industrial sensors. Its seamless compatibility with SMT also boosts assembly efficiency and yield, reducing production costs .

- Cost-Effective Performance: Compared to premium finishes like electroless nickel immersion gold (ENIG) and ENEPIG, immersion tin cuts process costs by 30–40% while maintaining high performance. This makes it a cost-efficient choice for mid-to-high-end consumer electronics, where balancing quality and budget is critical .

- Reliable Lead-Free Soldering: The tin layer offers exceptional wettability with lead-free solders (e.g., Sn-Ag-Cu), ensuring strong, durable solder joints even at the higher reflow temperatures (250–260℃) required for lead-free assembly. This reliability is validated by our clients’ long-term field performance data .

3.2 Main Disadvantages & Challenges

- Tin Whisker Growth Risk: Over time, tin whiskers—tiny conductive filaments—may form, posing short-circuit risks. Shenzhen Huaruixin’s field-proven solution: post-process baking at 150℃ for 1 hour and strict storage in a dry, low-humidity environment. We also recommend using finished products within 6 months to eliminate this risk entirely .

- Solder Mask Compatibility Challenges: Incompatible solder mask materials or inadequate pre-treatment can lead to mask peeling during the chemical bath. Shenzhen Huaruixin mitigates this by conducting rigorous material testing and tailoring pre-etching parameters to each FPC substrate—ensuring zero mask defects in production.

- Not Suitable for Contact Switch Designs: The tin layer has limited wear resistance; repeated mechanical contact (e.g., switch contacts) can cause abrasion and reduced conductivity. For these applications, Shenzhen Huaruixin’s engineers recommend ENIG or Ni/Au finishes, which offer superior wear performance .

- Multiple Reflow & Electrical Testing Considerations: Multiple reflow cycles can degrade the tin layer; we recommend nitrogen (N₂) atmosphere protection for secondary soldering. Additionally, the tin layer’s conductivity may cause false electrical test readings—our team optimizes test probe pressure and contact time to ensure accurate results .

4. Critical Design & Production Precautions for FPC Immersion Tin

Overcoming immersion tin’s challenges requires proactive design and strict production control. Based on years of global project experience, Shenzhen Huaruixin Electronics has developed a set of actionable guidelines to ensure success—from design to delivery. These guidelines are specifically tailored to address common pain points such as solder mask peeling, tin whisker growth, and false electrical test readings, which are critical for high-reliability immersion tin FPC production. Below are the critical precautions and mitigation strategies:

4.1 Design Phase Precautions

- Solder Mask Design Best Practices: Maintain a minimum 0.1 mm gap between solder mask and copper pads to prevent edge erosion. Avoid sharp corners in mask openings (a common peeling trigger). Shenzhen Huaruixin’s DFM (Design for Manufacturing) team offers free pre-production reviews to optimize solder mask layouts and eliminate potential defects.

- Pad Size & Thickness Specifications: Design pads with sufficient area to ensure uniform tin deposition. Specify tin layer thickness between 0.8–1.2 μm (per IPC-4554)—too thin reduces protection, while too thick increases tin whisker risk. Our engineering team provides detailed specification guidance to align with your application needs .

- Avoid Immersion Tin for Contact Switch Applications: For FPCs requiring repeated mechanical contact (e.g., keyboard flex cables), steer clear of immersion tin. Shenzhen Huaruixin recommends ENIG or immersion silver finishes, which offer superior wear resistance and long-term conductivity.

4.2 Production Process Controls

- Pre-Treatment Optimization: Strictly control micro-etching depth (0.5–1.0 μm) to ensure copper surface cleanliness without over-etching. Cold tin predip is mandatory to protect solder mask edges and prevent mouse bite defects— a standard step in our production process .

- Real-Time Bath Chemistry Control: Monitor tin ion concentration, pH value, and temperature 24/7. Shenzhen Huaruixin uses state-of-the-art Crystallizer® equipment to control copper content in the bath, extending bath life by 20% and reducing chemical consumption—lowering your production costs .

- Post-Treatment & Storage Protocols: Implement 3–4 stage rinsing to remove all residual chemicals. Post-process baking at 150℃ for 1 hour inhibits tin whisker growth. Store finished products in a controlled environment (RH < 50%, temperature 15–25℃) and use within 6 months—our team provides detailed storage guidelines for global shipping and handling.

- Reflow & Testing Optimization: Use N₂ atmosphere for multiple reflow cycles to minimize tin oxidation. Our quality team optimizes electrical test parameters (probe pressure, contact time) to avoid false readings, ensuring 100% accurate testing results.

5. Typical Application Fields of Immersion Tin FPC

Immersion tin’s unique blend of precision, lead-free compliance, and cost-effectiveness has made it a staple in industries where performance and scalability matter most. Shenzhen Huaruixin Electronics has supplied custom immersion tin FPC solutions to global clients across the following high-growth sectors, supporting their product innovation and market expansion:

- Automotive Electronics: Trusted in ECUs, battery management systems (BMS), automotive sensors, and in-vehicle infotainment systems. Its lead-free compliance and exceptional solderability meet strict automotive reliability standards (e.g., AEC-Q200). A standout example: Shenzhen Huaruixin’s immersion tin FPCs for automotive BMS passed 1000 thermal cycles (-40℃ to 125℃) with zero failures, exceeding client expectations <superscript>4. Another successful case: We partnered with a European leading automotive component supplier to develop high-density immersion tin FPCs for their next-gen electric vehicle (EV) battery monitoring modules. The client’s core demands were fine-pitch compatibility (0.3mm pad pitch), RoHS compliance, and 10+ year reliability. By optimizing our immersion tin pre-treatment process and solder mask design, we delivered FPCs with 99.98% soldering yield, and the modules have maintained stable performance in real-road tests across 5 European countries for over 2 years. This collaboration not only helped the client launch their EV model 3 months ahead of schedule but also reduced their component cost by 28% compared to their previous ENIG finish solution.

- Consumer Electronics: The top choice for smartphones, tablets, wearables (smartwatches, fitness trackers), and laptops. Its fine-line adaptability and flat surface make it ideal for compact, high-density FPCs like camera flex cables and display connectors—critical components in today’s slim, feature-rich devices. For consumer electronics brands pursuing high-volume production and consistent quality, immersion tin FPC offers a cost-effective alternative to expensive finishes while meeting strict solderability requirements for SMT assembly. A typical application is the 0.2mm line-space flex cables in premium smartphone foldable screens, where our immersion tin process ensures uniform layer thickness and excellent bend resistance.

- Industrial Automation: Reliable in industrial sensors, motor controllers, and robotic arm flex cables. Its press-fit compatibility and resistance to harsh industrial environments (temperature fluctuations, humidity) ensure consistent performance in demanding factory settings.

- LED Lighting: Essential for high-power LED flex PCBs (automotive headlights, street lighting). The good thermal conductivity and solderability of immersion tin ensure efficient heat dissipation—extending LED lifespan and reducing maintenance costs .

6. Partner with Shenzhen Huaruixin Electronics for Reliable Immersion Tin FPC Solutions

As a global leader in FPC/PCB manufacturing, Shenzhen Huaruixin Electronics turns immersion tin technology into reliable, tailored solutions for global clients. Our competitive edge lies in: strict process controls that eliminate defects, free DFM support to optimize your design for manufacturability, and comprehensive quality testing (including X-ray fluorescence for tin thickness measurement and AOI for surface inspection). Whether you need quick-turn prototype immersion tin FPC or mass-production immersion tin FPC for consumer electronics, every product we produce is engineered to meet your exact specifications and exceed industry standards.

Have an FPC project requiring immersion tin surface finish? We’re ready to partner with you. For more industry insights, technical resources, or to discuss your project needs—whether it’s automotive-grade immersion tin FPC, fine-pitch immersion tin FPC, or cost optimization for mass production—visit our website www.hrxfpc.com or email us at sales@hrxfpc.com. Our team of experts is eager to exchange ideas, provide guidance, and help bring your project to life—with the quality and reliability that set global leaders apart.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP