Search

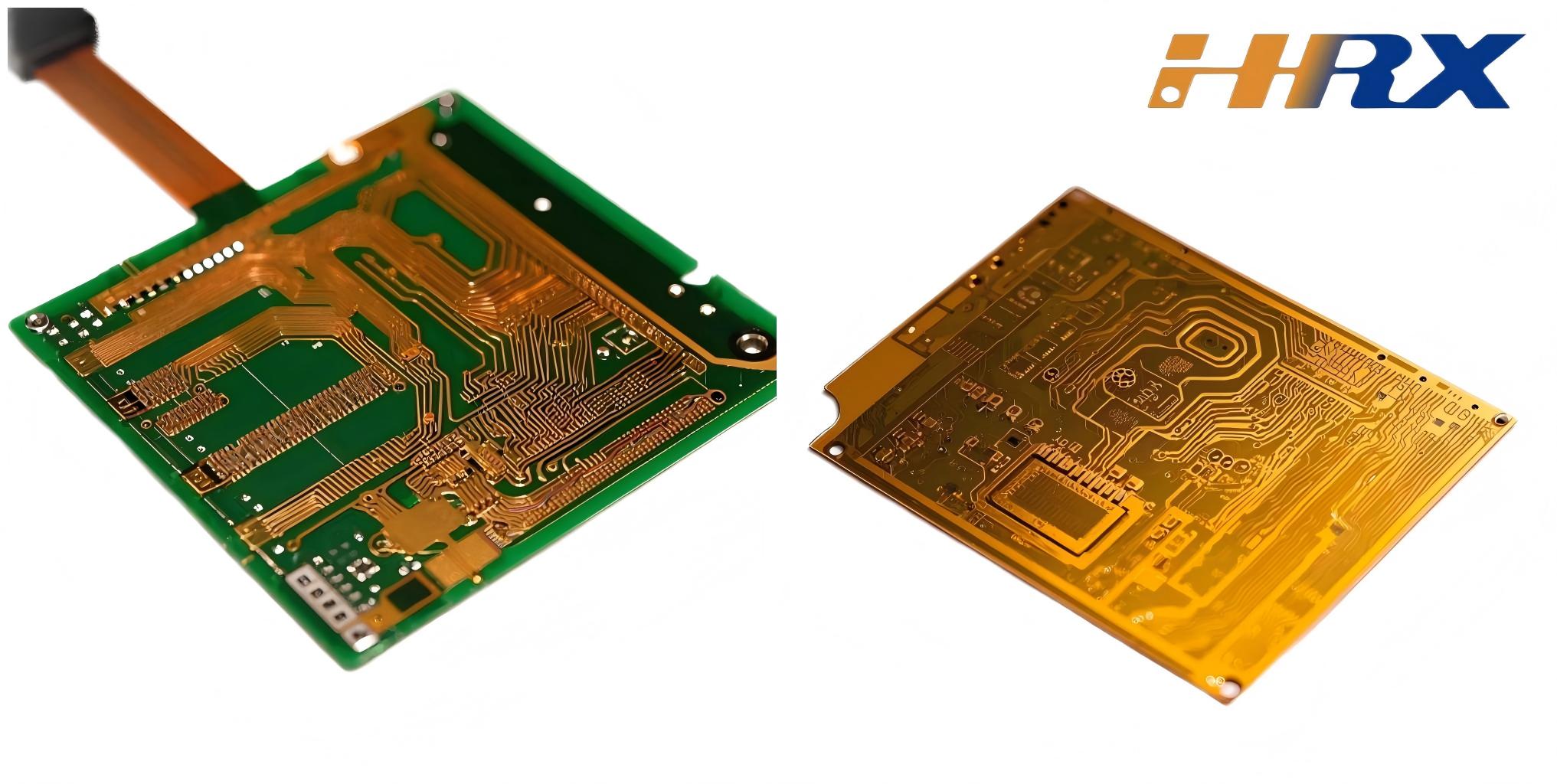

FPC Immersion Gold Process: Flow, Advantages, Applications & Manufacturing Insights

- Jan 06,2026

-

Share

In the realm of Flexible Printed Circuit (FPC) manufacturing, surface treatment is a critical process that directly determines the electrical performance, reliability, and service life of the product. Among the common surface treatment technologies for FPC, the Immersion Gold Process (also known as Electroless Nickel Immersion Gold, ENIG) stands out due to its excellent conductivity, corrosion resistance, and solderability. As a global ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex boards, Shenzhen Huaruixin Electronics Co., Ltd. has accumulated rich practical experience in the immersion gold process. This blog will delve into the core details of the FPC immersion gold process, including its workflow, technical characteristics, advantages and disadvantages, key considerations in design and production, as well as its wide-ranging applications.

1. An Overview of FPC Immersion Gold Process Workflow

The FPC immersion gold process is a chemical deposition technology that forms a uniform nickel-gold coating on the surface of the FPC copper layer through chemical reactions, without the need for external power supply. The standard workflow, summarized by Shenzhen Huaruixin Electronics based on years of production practice, includes the following key stages :

1. Pre-treatment: This is the foundation to ensure the adhesion of the gold layer. First, degreasing cleaning is performed using alkaline or acidic solutions to remove grease, fingerprints, and organic contaminants on the FPC surface. Then, micro-etching treatment is carried out with dilute sulfuric acid or sodium persulfate solution to slightly corrode the copper surface, remove the oxide layer, and roughen the surface. Finally, acid pickling activation is performed with hydrochloric acid or dilute sulfuric acid to completely eliminate residual oxides and activate the copper surface .

2. Pattern Transfer: Photosensitive dry film or liquid photoresist is coated on the FPC surface, and then ultraviolet exposure is performed through a mask. After development, the pad or circuit areas that need gold deposition are exposed, while other areas are protected to achieve selective gold deposition .

3. Electroless Nickel Plating: The activated FPC is immersed in an electroless nickel plating solution containing a reducing agent such as sodium hypophosphite. A nickel layer of 1-5μm is deposited on the copper surface as the base of the gold layer, which can prevent the mutual diffusion of copper and gold and enhance the corrosion resistance .

4. Electroless Gold Plating: The FPC with the nickel layer is immersed in a gold plating solution containing gold salts, reducing agents, and additives. Gold ions in the solution are reduced through a displacement reaction and deposited on the nickel layer to form a thin gold layer with a thickness of 0.05-0.2μm .

5. Post-treatment: The protective dry film or photoresist is removed, and the FPC is rinsed with pure water to remove residual chemicals, then dried with hot air or nitrogen. Finally, selective coating of antioxidants or cover films is performed to protect non-gold-plated areas .

6. Inspection and Quality Control: X-ray fluorescence (XRF) is used to detect the thickness of the nickel and gold layers. Adhesion tests (such as tape peeling test) and solderability tests are conducted to ensure the quality of the coating. Microscopic observation is also performed to check for defects such as pinholes and bubbles .

2. Technical Characteristics of FPC Immersion Gold Process

The FPC immersion gold process has distinct technical characteristics that make it suitable for various high-demand scenarios. Shenzhen Huaruixin Electronics has summarized the following core characteristics based on extensive production practice:

- Uniform Coating Thickness: Due to the chemical deposition method, the gold layer and nickel layer formed by the immersion gold process are highly uniform, even on small and dense pads. This ensures consistent electrical performance across the entire FPC .

- Excellent Surface Flatness: The immersion gold process produces a very flat surface, which improves the reliability of solder joints and the alignment accuracy of components during assembly. It is particularly suitable for fine-pitch pins and components with small solder joints .

- Good Chemical Stability: Gold has excellent chemical inertness, and the nickel-gold composite layer can effectively prevent the copper layer from oxidation. FPC products treated with immersion gold have a long shelf life, and their performance does not degrade significantly even after storage for up to one year .

- Low Contact Resistance: The gold layer has extremely low resistivity, which can ensure excellent electrical conductivity and low contact resistance. This makes it highly suitable for high-frequency and high-speed signal transmission scenarios .

- Compatibility with Flexible Substrates: The immersion gold process operates at a low temperature (≤60°C), which avoids deformation of the polyimide (PI) substrate of FPC and ensures the flexibility of the product .

3. Advantages and Disadvantages of FPC Immersion Gold Process

3.1 Advantages

Shenzhen Huaruixin Electronics has verified through numerous project cases that the FPC immersion gold process has the following significant advantages:

- Superior Electrical Performance: Gold's low resistivity (4.3 times lower than nickel) minimizes signal loss, making it ideal for high-frequency applications such as 5G antennas and RF modules. The low contact resistance (as low as 0.1Ω) ensures stable signal transmission .

- Strong Corrosion and Wear Resistance: The nickel-gold composite layer can withstand harsh environments. It has excellent resistance to salt spray corrosion (up to 1000 hours of salt spray test) and can resist oxidation and wear in humid and corrosive environments .

- Excellent Solderability and Reworkability: The immersion gold layer maintains good solderability even after multiple reflow soldering processes, which facilitates the assembly and rework of electronic products. The stable nickel layer provides a reliable soldering base .

- Long-term Reliability: The chemical stability of the gold layer ensures that FPC products can operate stably for a long time. This is crucial for high-reliability applications such as medical devices and automotive electronics .

- Environmental Friendliness: The immersion gold process is lead-free and complies with RoHS directives, meeting the global environmental protection requirements for electronic products .

3.2 Disadvantages

While the immersion gold process has many advantages, it also has certain limitations, which Shenzhen Huaruixin Electronics reminds customers to consider when selecting the process:

- Higher Cost: Gold is a precious metal, and the immersion gold process involves two chemical deposition steps (nickel and gold), resulting in higher material and processing costs compared to other surface treatment processes such as tin plating .

- Risk of Black Pad Phenomenon: Improper process control (such as excessive pH value or temperature of the plating solution) can lead to the formation of a black pad on the nickel layer, which impairs the solder joint strength and reliability .

- Limited Modifiability: Once the immersion gold coating is formed, it is difficult to modify or repair, which limits the flexibility of design adjustments .

- Low Wear Resistance for High Plug-in Frequency Scenarios: The gold layer of the immersion gold process is thin (0.05-0.2μm), so its wear resistance is inferior to that of electroplated hard gold. It is not suitable for gold finger areas that require frequent plugging and unplugging .

4. Key Considerations in FPC Immersion Gold Process Design and Production

To ensure the quality of FPC products treated with immersion gold, Shenzhen Huaruixin Electronics emphasizes that strict control of details in the design and production processes is essential. The following are the key considerations and corresponding preventive measures:

4.1 Design Stage Considerations

- Pad Design: The pad size should be reasonably designed to avoid too small pads, which may lead to uneven gold deposition. For fine-pitch pads, the spacing should be strictly controlled to prevent short circuits caused by excessive gold deposition. Shenzhen Huaruixin Electronics recommends that the pad size should not be less than 0.2mm×0.2mm for immersion gold process.

- Circuit Layout: Avoid sharp corners in the circuit design, as they are prone to current concentration during the deposition process, resulting in uneven coating. The circuit width should be uniform to ensure consistent current distribution.

- Substrate Selection: Choose high-quality polyimide (PI) substrates with good thermal stability and chemical resistance. Inferior substrates may deform or react with the plating solution during the immersion gold process, affecting product quality.

4.2 Production Stage Considerations

- Pre-treatment Control: Ensure thorough cleaning and activation of the FPC surface. Residual contaminants or oxides will affect the adhesion of the nickel and gold layers. Shenzhen Huaruixin Electronics uses ultrasonic cleaning technology to improve the cleaning effect and strictly controls the concentration and temperature of the cleaning and etching solutions .

- Plating Solution Parameter Control: Strictly monitor the temperature, pH value, and concentration of gold and nickel ions in the plating solution. Small changes in these parameters can significantly affect the thickness and quality of the coating. For example, the temperature of the electroless nickel plating solution should be controlled at 45-55°C, and the pH value at 4.5-5.5. Shenzhen Huaruixin Electronics uses automated monitoring equipment to realize real-time adjustment of plating solution parameters .

- Tension Control of FPC: During the production process, the FPC should be operated under low tension to prevent curling or tearing. Shenzhen Huaruixin Electronics uses special fixtures to fix the FPC, ensuring the flatness of the board surface during the immersion process .

- Post-treatment Cleaning and Drying: Thoroughly rinse the FPC with pure water after plating to remove residual plating solution, which can cause corrosion if left. The drying process should be carried out in a timely manner to avoid water stains on the surface. Shenzhen Huaruixin Electronics adopts nitrogen drying technology to ensure the drying effect and prevent oxidation .

- Quality Inspection: Establish a comprehensive quality inspection system. In addition to testing the thickness and adhesion of the coating, conduct regular solderability and corrosion resistance tests. For high-precision products, use scanning electron microscopes (SEM) to observe the microstructure of the coating .

4.3 Prevention of Common Problems

- Black Pad Prevention: Control the plating time and temperature, avoid over-plating, and regularly filter the plating solution to remove impurities. Add appropriate stabilizers to the plating solution to prevent the oxidation of the nickel layer .

- Coating Peeling Prevention: Strengthen pre-treatment to ensure the surface is clean and activated. Control the plating rate to avoid excessive deposition speed, which may lead to poor adhesion. Conduct adhesion tests regularly to detect problems in time .

- Uneven Coating Prevention: Ensure uniform stirring of the plating solution, reasonable arrangement of the FPC in the plating tank, and avoid overlapping or blocking. Adjust the distance between the FPC and the anode (if any) to ensure uniform current distribution.

5. Wide Applications of FPC Immersion Gold Process

Benefiting from its excellent performance, the FPC immersion gold process is widely used in various high-end electronic fields. Shenzhen Huaruixin Electronics has provided FPC products with immersion gold treatment for many customers in these fields, accumulating rich application experience:

- Consumer Electronics: This is the most extensive application field of FPC immersion gold process. It is used in foldable mobile phones (hinge connection circuits), smart watches (sensor connection lines), Bluetooth headsets (charging box circuits), and tablet computers (internal connection flexible boards). The excellent conductivity and flexibility of immersion gold FPC meet the requirements of miniaturization and high performance of consumer electronics .

- Automotive Electronics: In the automotive industry, immersion gold FPC is used in automotive infotainment systems, in-vehicle USB interface circuits, engine bay sensors, and LED automotive lighting systems. It can withstand the harsh environment of high temperature, high humidity, and vibration in the automotive environment, ensuring long-term reliable operation. Automotive electronics account for 38% of the sales of immersion gold FPC .

- Medical Devices: Medical devices such as pacemakers, blood glucose meters, and portable medical sensors have high requirements for the reliability and biocompatibility of FPC. The immersion gold process provides excellent corrosion resistance and stable electrical performance, ensuring the safe and reliable operation of medical devices in the human body environment .

- 5G Communication Equipment: 5G base stations, RF modules, and antennas require FPC with low signal loss and high frequency performance. The immersion gold process, with its low contact resistance and excellent high-frequency signal transmission capabilities, has become the preferred surface treatment technology for 5G communication FPC .

- Industrial Control: In industrial control systems, immersion gold FPC is used in small industrial sensors (temperature and humidity sensors), programmable logic controllers (PLCs), and industrial robot connection lines. It can adapt to the harsh industrial environment and ensure the stability and reliability of the control system .

6. Conclusion

The FPC immersion gold process is an important surface treatment technology that provides excellent electrical performance, reliability, and environmental adaptability for FPC products. However, it also has the characteristics of high cost and strict process control requirements. As a professional FPC, PCB, and rigid-flex board manufacturer, Shenzhen Huaruixin Electronics has rich experience in the immersion gold process. We can provide customers with customized ODM/OEM solutions according to their specific needs, ensuring the quality and performance of products while optimizing costs.

If you have project requirements, we are just a professional manufacturer. Welcome to contact us at any time. For industry knowledge, you can also visit our website: www.hrxfpc.com to learn more information or email us at sales@hrxfpc.com for consultation, to exchange, learn and guide together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP