Search

FPC for Industrial Control: Key Features, Design Tips & Trusted Manufacturing

- Aug 11,2025

-

Share

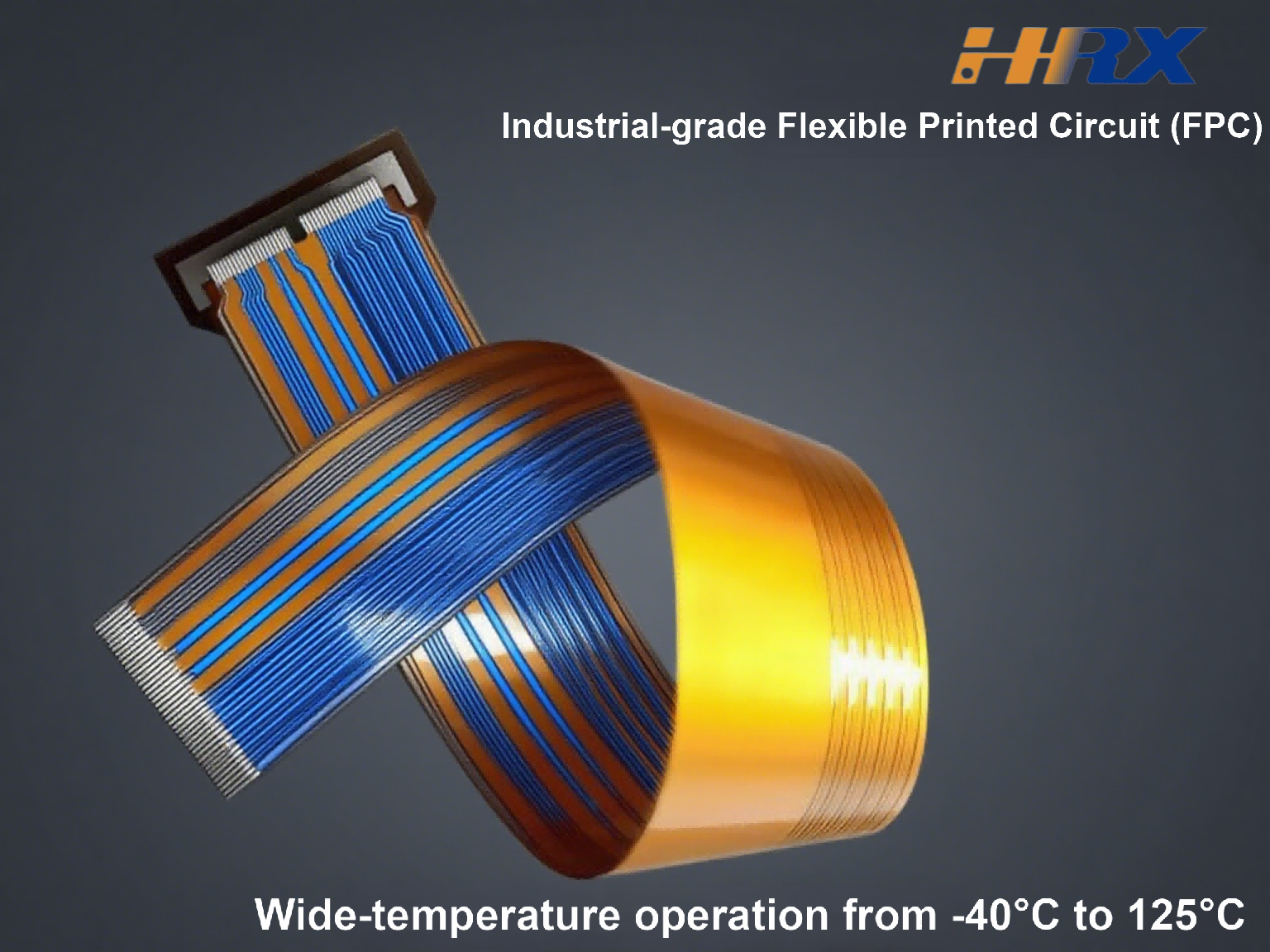

In the fast-evolving landscape of industrial automation, Flexible Printed Circuits (FPC) have become indispensable components, driving precision and reliability in control systems worldwide. Unlike standard FPCs used in consumer electronics, industrial control FPCs are engineered to thrive in harsh operating environments, making them a cornerstone of modern manufacturing, energy, and robotics sectors. This blog explores the unique attributes of FPC for industrial control, critical design and production considerations, and why Shenzhen Huaruixin Electronics Co., Ltd. stands as a leading partner for industrial FPC solutions.

Unique Features of Industrial Control FPCs

Industrial environments demand FPCs that go beyond basic functionality. Here’s what sets industrial-grade flexible printed circuits apart:

High-Temperature Resistance with Polyimide Substrates

Industrial control systems often operate in extreme thermal conditions, from freezing cold warehouses to high-heat factory floors. FPCs for industrial control utilize polyimide substrates—a material renowned for its exceptional thermal stability, withstanding continuous operating temperatures ranging from -55°C to 125°C (and up to 200°C in specialized variants). This resistance prevents substrate degradation, ensuring consistent electrical performance even under thermal stress.

Enhanced Mechanical Durability & Flex Endurance

Vibrations, shocks, and repeated motion are common in industrial machinery, from robotic arms to conveyor systems. Industrial FPCs are designed with reinforced cover layers (typically made of polyimide or polyester) and rolled annealed (RA) copper conductors to resist fatigue. These circuits undergo rigorous flex endurance testing, enduring 10,000+ bending cycles without conductor fracture or insulation failure—a critical metric for long-term reliability.

Superior Environmental Resistance

Dust, moisture, chemicals, and corrosion pose constant threats in industrial settings. Industrial control FPCs address these challenges with epoxy-based adhesives, gold-plated contact pads for corrosion resistance, and optional conformal coatings (such as acrylic or silicone) to seal against contaminants. This protective design ensures stable performance in environments where standard PCBs would fail.

Optimized Signal Integrity for Industrial IoT

In industrial automation, real-time data transmission is non-negotiable. FPCs for industrial control integrate controlled impedance routing, ground planes, and EMI shielding layers (using copper foils or conductive inks) to minimize electromagnetic interference. This design ensures accurate signal transmission between sensors, PLCs (Programmable Logic Controllers), and actuators—vital for IIoT (Industrial Internet of Things) applications and precision control systems.

Space-Efficient & Customizable Form Factors

Industrial machinery often has compact, irregularly shaped enclosures. FPCs’ flexibility allows them to conform to 3D structures, replacing bulky wiring harnesses with streamlined, lightweight designs. This space-optimized routing reduces assembly complexity, lowers weight, and improves system efficiency—key advantages in applications like control panels, motor drives, and embedded sensors.

Critical Design & Production Considerations for Industrial FPCs

Developing reliable industrial control FPCs requires meticulous attention to design and manufacturing processes. Here are the key factors to prioritize:

Material Selection for Industrial Environments

The foundation of a high-performance industrial FPC lies in material choice. Beyond polyimide substrates, select high-Tg (glass transition temperature) laminates for thermal stability, high-purity copper foils (≥99.9% purity) for low resistance, and flame-retardant cover layers (meeting UL 94 V-0 standards) for safety. For chemical-exposed environments, opt for fluoropolymer-based adhesives to resist solvents and oils.

Design for Manufacturability (DFM) & Mechanical Stress

Industrial FPCs must withstand mechanical stress, so design with rounded corners (to reduce stress concentration), strain relief areas in flex zones, and minimum bend radius (typically 10x the FPC thickness) to prevent conductor damage. Collaborate with manufacturers early in the design phase to leverage DFM expertise—this ensures producibility while maintaining performance.

Rigorous Testing & Compliance

Industrial FPCs must meet stringent standards. Implement electrical testing (continuity, insulation resistance, hipot testing) and environmental testing (thermal cycling, humidity testing, salt spray testing) to validate reliability. Compliance with industry standards such as IPC-A-600 (for printed boards) and IEC 61076 (for industrial connectors) is non-negotiable for global market acceptance.

Precision Manufacturing with Advanced Equipment

Production of industrial control FPCs demands state-of-the-art technology. Key processes include laser drilling for microvias (ensuring high-density interconnects), automated optical inspection (AOI) for defect detection, and electroless nickel immersion gold (ENIG) plating for durable solder joints. Manufacturers with ISO 9001 certifications demonstrate a commitment to quality.

Why Choose Shenzhen Huaruixin Electronics for Industrial Control FPCs?

Shenzhen Huaruixin Electronics Co., Ltd. is a globally recognized ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex printed boards—with deep expertise in industrial control applications. Here’s why they stand out:

Specialized Experience in Industrial FPC Solutions

Huaruixin’s engineering team has decades of experience designing FPCs for industrial environments. They understand the unique challenges of thermal stress, mechanical fatigue, and EMI, delivering customized solutions for robotics, energy management, and smart manufacturing systems.

Large-Scale Manufacturing with Precision

Equipped with advanced facilities—including LDI (Laser Direct Imaging) systems and automated assembly lines—Huaruixin ensures high-volume production without compromising quality. Their manufacturing process adheres to strict IPC standards, with 100% AOI and functional testing for every industrial FPC.

Commitment to Quality & Reliability

From material sourcing (partnering with top-tier substrate suppliers) to final inspection, Huaruixin prioritizes reliability. Their industrial FPCs undergo rigorous testing, including thermal shock testing (-55°C to 125°C) and 50,000+ flex cycles, ensuring they meet the longest service life requirements.

Partner with Huaruixin for Your Industrial FPC Needs

If you’re seeking high-performance FPC for industrial control applications, Shenzhen Huaruixin Electronics is your trusted partner. With their technical expertise, advanced manufacturing capabilities, and commitment to quality, they deliver solutions tailored to your unique requirements.

For more insights into industrial FPC design or to discuss your project, visit our website at www.hrxfpc.com or email our sales team at sales@hrxfpc.com Let’s collaborate to drive innovation in your industrial control systems.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP