Search

FPC Connectors: Key Specs, Design Tips & Top Manufacturer Guide

- Jul 25,2025

-

Share

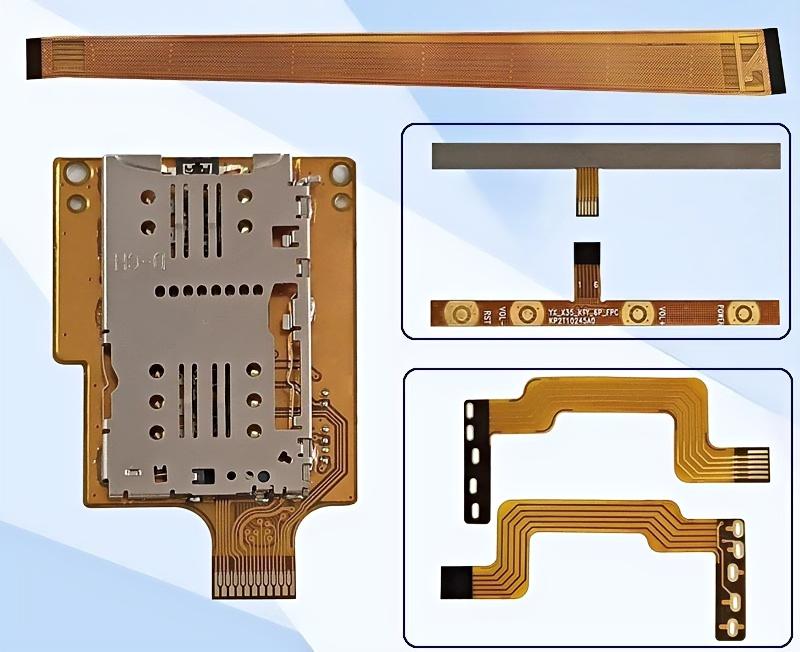

In the rapidly evolving world of electronics, flexible printed circuits (FPCs) have become the backbone of compact, high-performance devices—from foldable smartphones to automotive sensors. At the core of every FPC’s functionality lies the FPC connector—a critical interface that bridges flexible circuits to rigid PCBs, components, or other FPCs. Choosing the right FPC connector and integrating it effectively can make or break a product’s reliability. Below, we break down the essential considerations for FPC connectors and why partnering with an expert manufacturer like Shenzhen Huaruixin Electronics is a game-changer.

Critical FPC Connector Specifications & Design Considerations

1. Pitch and Pin Count: The Foundation of Compatibility

FPC connectors are defined by their pitch (the distance between adjacent pins), ranging from 0.3mm (ultra-fine) to 2.54mm (standard). Fine-pitch connectors (0.3mm, 0.5mm) are ideal for miniaturized devices like wearables, while larger pitches (1.0mm+) suit industrial applications requiring robust connections. Matching the connector’s pin count to the FPC’s contact pads is non-negotiable—under-matching leads to signal loss, over-matching wastes space.

2. Connector Types: ZIF vs. LIF vs. Board-to-Board

ZIF (Zero Insertion Force) Connectors: Feature a lever or slider to secure the FPC, eliminating insertion force. Perfect for frequent FPC replacements (e.g., in test equipment) and preventing FPC contact pad damage.

LIF (Low Insertion Force) Connectors: Require minimal force for insertion, balancing ease of use with stability—common in consumer electronics.

Board-to-Board FPC Connectors: Connect two FPCs or an FPC to a rigid PCB, often with stackable designs for 3D packaging.

Selecting the right type depends on FPC thickness (0.1mm to 0.3mm typical) and flexibility—thicker FPCs may need larger housings to avoid crimping.

3. Environmental and Mechanical Durability

FPC connectors must withstand harsh conditions:

Temperature Range: Industrial-grade connectors handle -40°C to 125°C; automotive variants often exceed 150°C.

Moisture and Dust Resistance: IP67/IP68-rated connectors protect against water ingress in outdoor or medical devices.

Vibration and Shock: SMT (Surface Mount Technology) mounted connectors with locking mechanisms resist loosening in automotive or aerospace applications.

Gold-plated contacts (20-30 microinches) reduce corrosion and ensure low contact resistance (<50mΩ) for consistent signal transmission.

4. Signal Integrity and EMI/EMC Compliance

In high-speed data applications (e.g., 5G modules, HDMI over FPC), impedance matching (50Ω, 75Ω) between the FPC and connector is critical to avoid signal reflection. Shielded FPC connectors with grounded metal shells mitigate EMI (Electromagnetic Interference), while twisted-pair FPC designs reduce crosstalk.

5. Assembly and SMT Compatibility

For mass production, connectors must integrate seamlessly with SMT lines. Features like pick-and-place compatibility (tape-and-reel packaging) and reflow solder tolerance (260°C for 30 seconds) streamline manufacturing. Huaruixin’s in-house assembly expertise ensures precise alignment between FPCs and connectors, minimizing post-production failures.

Why Shenzhen Huaruixin Electronics Leads in FPC Connector Solutions

Shenzhen Huaruixin Electronics Co., Ltd. combines decades of ODM/OEM experience with cutting-edge manufacturing to deliver FPC, PCB, and rigid-flex solutions optimized for connector performance. Here’s what sets Huaruixin apart:

End-to-End Expertise: From FPC design (considering connector pitch and thickness) to connector sourcing and assembly, Huaruixin ensures compatibility at every step.

Customization: Engineers tailor FPCs with connector-specific features—such as reinforced contact pads or EMI shielding—for unique applications (e.g., foldable displays, IoT sensors).

Quality Assurance: Rigorous testing includes thermal cycling, vibration, and contact resistance checks, ensuring connectors meet IPC and automotive standards (ISO 9001).

Ready to Elevate Your FPC Project?

Whether you need help selecting the right FPC connector, designing a custom flexible circuit, or scaling production, Huaruixin’s team is here to support you.

Explore industry insights at www.hrxfpc.com

Discuss your project: sales@hrxfpc.com

Partner with Huaruixin to ensure your FPC connectors deliver reliability, performance, and longevity—today and tomorrow.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP