Search

FPC Base Material Lamination: Shenzhen Huaruixin Electronics' Professional Solutions for High-Reliability FPC Manufacturing

- Sep 05,2025

-

Share

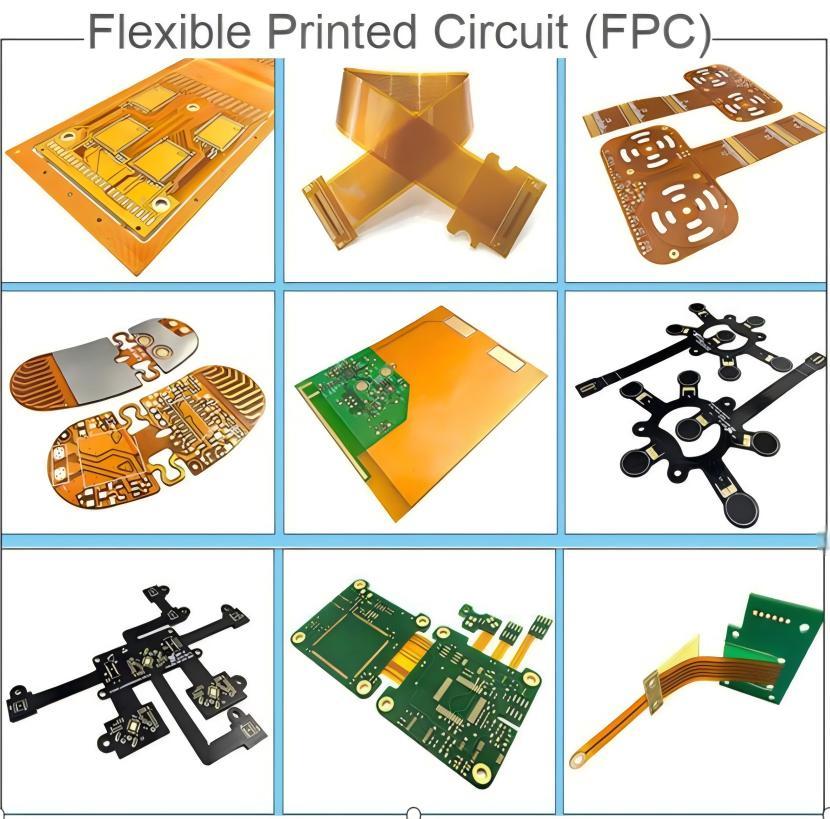

Flexible Printed Circuits (FPC) are indispensable in modern electronics—powering devices from consumer electronics to automotive and aerospace systems. At the core of FPC manufacturing lies the FPC base material lamination process: the critical step that forms the "copper foil - base material" substrate, directly defining FPC performance, mechanical flexibility, and long-term reliability. As a global-leading ODM/OEM manufacturer specializing in FPC, PCB, and Rigid-Flex Printed Board design, development, and mass production, Shenzhen Huaruixin Electronics Co., Ltd. (Huaruixin) has refined its lamination expertise to meet stringent industry demands. This blog details Huaruixin’s advanced approach to FPC lamination, its unique competitive edges, key quality controls, and how it delivers consistent results for high-reliability applications.

1. Huaruixin’s Advanced Processes for FPC Base Material Lamination

Huaruixin’s FPC lamination process adheres to IPC-6012/2221 standards and integrates proprietary technical optimizations, ensuring uniform bonding, minimal defects, and compliance with customer-specific requirements for flexible circuit substrates.

1.1 Standard Lamination for Adhesive-Based FPC Substrates

For most commercial FPC applications, Huaruixin utilizes a precision hot press lamination process for pre-treated electrolytic/rolled copper foil, thermosetting adhesive (e.g., acrylic, epoxy), and PI film (Polyimide film)—the foundational materials of FPC substrates.

Parameter Precision: The process is controlled via computerized systems to maintain:

Temperature: 180–220℃ (optimized for adhesive curing without PI film degradation)

Pressure: 30–50kg/cm² (ensures void-free bonding between copper foil and PI film)

Dwell Time: 30–60 minutes (tailored to adhesive thickness and copper foil grade)

Outcome: The result is a homogeneous FPC base substrate (analogous to PCB copper-clad laminates) with consistent thickness (±5μm tolerance) and peel strength ≥1.5N/mm—critical for withstanding repeated flexing in end-use devices.

1.2 Specialized Lamination for Adhesive-Free FPC Substrates

For high-reliability FPC applications (e.g., automotive electronics, medical devices, aerospace components), Huaruixin has developed a proprietary adhesive-free FPC lamination process. This eliminates risks associated with adhesive aging, outgassing, or thermal degradation.

Process Innovation: Instead of traditional adhesives, Huaruixin uses a high-temperature high-pressure (HTHP) lamination process (≥250℃) to induce strong intermolecular forces (van der Waals forces + chemical bonding) between the copper foil and PI film.

Key Advantages: The resulting adhesive-free FPC substrate offers:

Enhanced thermal stability (operating temperature: -65℃ to 260℃)

Improved chemical resistance (resistant to solvents, oils, and humidity)

Reduced substrate thickness (ideal for miniaturized electronics)

Quality Assurance: Each adhesive-free substrate undergoes 100% inspection for delamination resistance and dielectric strength (≥500V/μm), meeting AEC-Q200 standards for automotive FPCs.

2. Unique Competitive Edges of Huaruixin in FPC Lamination

Huaruixin’s leadership in FPC lamination stems from three core strengths that address industry pain points—customization, precision, and scalability.

2.1 Customized FPC Lamination Solutions for Diverse Applications

Unlike one-size-fits-all approaches, Huaruixin’s R&D team (comprising 15+ FPC engineering experts) designs tailored FPC lamination processes for specific use cases:

For wearable devices: Ultra-thin (≤0.1mm) adhesive-based substrates with low-temp lamination (180–190℃) to protect delicate components.

For industrial sensors: Flame-retardant (UL94 V-0) FPC substrates using halogen-free PI film and high-temp lamination (200–220℃).

For high-frequency FPCs (5G antennas): Low-loss PI film and controlled lamination pressure to maintain impedance stability (±1Ω).

2.2 Advanced Equipment & Real-Time Process Control

Huaruixin has invested in state-of-the-art FPC lamination equipment to ensure process repeatability:

Equipment: High-precision hot presses (from Mitsubishi Heavy Industries) with closed-loop temperature/pressure control (±1℃, ±0.5kg/cm²).

Monitoring: In-line optical inspection (AOI) systems detect voids, bubbles, or misalignment during lamination—reducing defect rates to <0.1%.

Traceability: Each substrate is assigned a unique QR code, linking to lamination parameters, raw material batches, and inspection data (compliant with ISO 9001 and IATF 16949).

2.3 Scalable Mass Production with Consistent Quality

As a large-scale FPC manufacturer, Huaruixin balances precision with volume:

Capacity: 50,000+ square meters of FPC substrates per month (supports high-volume orders for consumer electronics brands).

Quality Consistency: Statistical Process Control (SPC) is applied to all lamination lines, ensuring 99.8% yield for standard FPC substrates and 98.5% for adhesive-free variants.

3. Critical Quality Controls for FPC Lamination

Even the most advanced FPC lamination process requires rigorous controls to avoid common defects (e.g., bubbles, delamination, uneven thickness). Huaruixin prioritizes four key areas:

3.1 Raw Material Quality for FPC Substrates

Raw materials directly impact lamination outcomes—Huaruixin sources only Tier-1 materials and conducts strict incoming inspections:

Copper Foil: Tests for surface roughness (Ra ≤0.3μm), tensile strength (≥300MPa), and purity (99.99% Cu).

PI Film: Inspects for thickness uniformity (±3μm), dielectric constant (≤3.5 at 1GHz), and thermal conductivity (≥0.15W/m·K).

Adhesives: Validates curing speed, outgassing levels (≤1% weight loss at 200℃), and compatibility with PI/copper.

3.2 Stability of FPC Lamination Parameters

Minor deviations in temperature, pressure, or time can ruin substrates. Huaruixin mitigates this via:

Daily calibration of hot presses (using NIST-traceable sensors).

Real-time monitoring via PLC systems—alerts trigger if parameters deviate by >2%.

Batch testing: First-article inspection (FAI) for every production run to verify peel strength and void count.

3.3 Cleanroom Environment for FPC Lamination

Contamination (dust, oil, moisture) is a top cause of lamination defects. Huaruixin’s lamination workshops meet Class 10,000 cleanroom standards:

Temperature: 23±2℃; Humidity: 45±5% (prevents moisture absorption by PI film).

Personnel protocols: Anti-static clothing, air showers, and glove changes every 2 hours.

Air filtration: HEPA filters remove particles ≥0.3μm—critical for adhesive-free lamination.

3.4 Post-Lamination Inspection & Testing

Every FPC substrate undergoes comprehensive testing before moving to circuit patterning:

Visual Inspection: AOI systems check for bubbles, scratches, or delamination.

Mechanical Testing: Peel strength (per IPC-TM-650 2.4.9) and flex endurance (100,000+ cycles at 1mm bend radius).

Electrical Testing: Dielectric breakdown voltage (per IPC-TM-650 2.5.6) and copper conductivity (≥58MS/m).

4. Partner with Huaruixin for Your FPC Project

Whether you need standard adhesive-based FPC substrates for consumer electronics or custom adhesive-free FPCs for high-reliability applications, Huaruixin delivers turnkey solutions—from lamination to final FPC assembly.

Learn More: Visit our website www.hrxfpc.com for technical whitepapers on FPC lamination processes, case studies, and material specifications.

Get a Quote: Email our sales team at sales@hrxfpc.com with your FPC requirements (application, dimensions, performance needs)—we respond within 24 hours.

Industry Collaboration: Huaruixin welcomes partnerships for R&D on next-gen FPC technologies (e.g., flexible hybrid electronics, 3D-printed FPCs).

Join 200+ global clients (including automotive Tier-1 suppliers and medical device manufacturers) who trust Huaruixin for reliable, high-quality FPC lamination and manufacturing.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP