Search

FPC & PCB Etching Process: Advanced Solutions by Shenzhen Huaruixin Electronics

- Sep 05,2025

-

Share

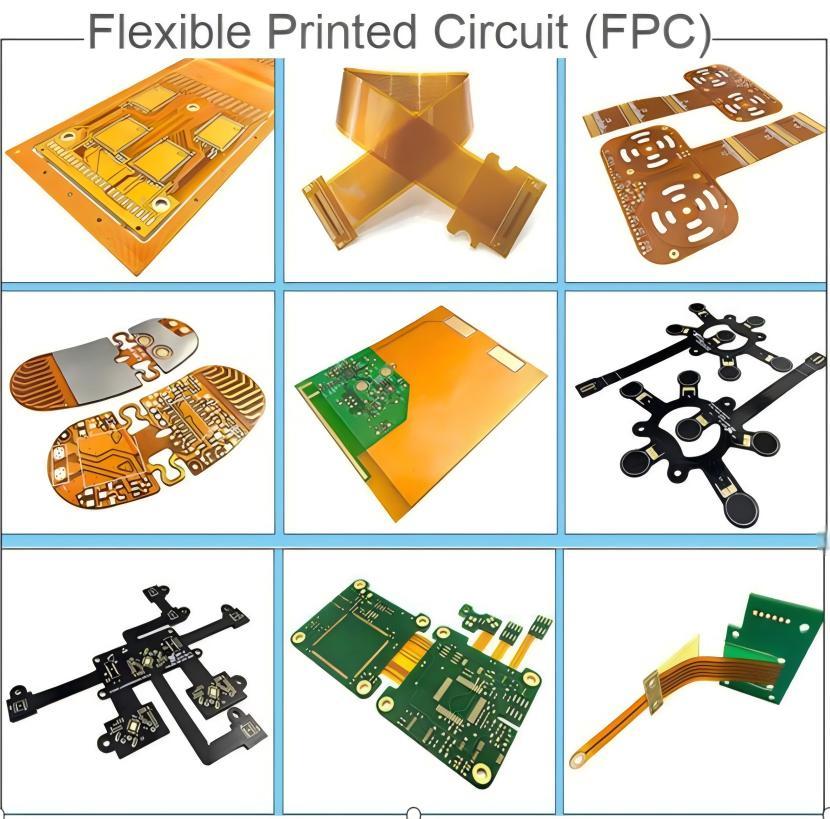

Etching is the backbone of FPC (Flexible Printed Circuit) and PCB (Printed Circuit Board) manufacturing, a precision step that strips excess copper foil to form intricate flex circuit traces and rigid circuit patterns. For FPCs—critical components in wearable devices, automotive electronics, and medical equipment—etching demands extra care to preserve the integrity of delicate PI substrate (Polyimide substrate) or PET substrate while ensuring circuit accuracy.

Typically, acidic etching solutions (e.g., ferric chloride etching solution, cupric chloride etching solution) target exposed copper foil (areas unprotected by dry film resist post-development), leaving only the dry film-covered copper as the desired circuit. The core chemical reaction driving this process is:

Cu + 2FeCl₃ = CuCl₂ + 2FeCl₂

Industry standards mandate strict process control: a temperature range of 40-50℃ and an etching rate of 1-2μm per minute. Deviations risk circuit edge roughness (too fast) or production bottlenecks (too slow). Post-etching, boards undergo rinsing, acidic neutralization (hydrochloric acid) , and drying to eliminate residual corrosives.

As a global FPC ODM/OEM, PCB manufacturer, and Rigid-Flex Printed Board supplier, Shenzhen Huaruixin Electronics Co., Ltd. elevates FPC and PCB etching with tailored technologies. Below is a detailed breakdown of our optimized processes, unique FPC-focused advantages, and critical quality controls—designed to meet the demands of high-precision flex circuits and rigid PCBs.

1. Huaruixin’s FPC & PCB Etching Process: Tailored for Precision

Custom Etching Solutions for FPC Substrates: Unlike generic solutions, we formulate ferric chloride etching solutions and cupric chloride etching solutions to match FPC substrate properties (e.g., PI substrate thickness, PET flexibility) and copper foil grades (e.g., rolled copper for high-flex applications). For ultra-thin FPCs (≤0.1mm), we reduce acid concentration by 15% to prevent substrate degradation while maintaining etching efficiency.

Automated Parameter Control for Flex Circuit Traces: FPC etching requires tighter tolerances than PCBs—our IoT-enabled systems monitor temperature (40-45℃ for PI substrates, 45-50℃ for rigid PCBs) in real time, avoiding fluctuations that cause circuit edge irregularities. We use laser thickness gauges to track copper removal, adjusting solution flow rate dynamically to keep the etching rate at 1.2-1.8μm/min—ideal for preserving fine flex circuit traces (≥0.1mm width).

FPC-Specific Post-Etching Treatment: For FPCs, traditional drying can warp PI substrates—we use vacuum freeze-drying to remove moisture without heat stress. Our post-etching workflow includes: 1) Three-stage countercurrent rinsing (cuts water use by 35% vs. single-stage) to eliminate residual etchant; 2) pH-controlled hydrochloric acid neutralization (target pH 6.8-7.2) to protect FPC adhesive layers; 3) Anti-tarnish coating for copper traces (critical for FPCs in humid environments).

2. Unique Advantages: FPC Expertise That Sets Us Apart

Dual-Sided Uniform Etching for Rigid-Flex Boards: Rigid-Flex Printed Boards combine PI substrate (flex sections) and FR-4 (rigid sections)—a challenge for uniform etching. Huaruixin’s dual-nozzle etching system adjusts pressure (0.2MPa for flex sections, 0.4MPa for rigid) and nozzle angle, achieving 99% etching uniformity across both regions. This ensures consistent circuit impedance—vital for high-frequency Rigid-Flex applications (e.g., 5G devices).

Eco-Friendly Etching for Sustainable FPC Production: We integrate a closed-loop etching solution recycling system that reclaims 88% of used ferric chloride/cupric chloride, reducing hazardous waste. For FPC manufacturers focused on sustainability, this aligns with global ESG standards while cutting material costs. Wastewater from rinsing is treated to meet Class A discharge standards, supporting green FPC manufacturing.

AOI-Integrated Quality for FPC Traceability: FPCs are prone to dry film resist peeling (a major cause of etching defects). We add pre-etching automated optical inspection (AOI) to detect dry film bubbles or gaps on PI substrates, repairing issues before etching. Post-etching, AOI scans for undercutting or over-etching of flex circuit traces, with data logged in our MES system for full product traceability—critical for medical FPCs and automotive electronics.

3. Critical Considerations for FPC & PCB Etching

Dry Film Adhesion on PI Substrates: PI substrates have low surface energy, making dry film adhesion tricky. We pre-treat PI surfaces with plasma cleaning (increases adhesion by 40%) and control lamination parameters (110℃, 0.4MPa, 1.8m/min) to prevent peeling during etching—this eliminates 95% of FPC etching defects.

Etching Solution Concentration Stability: For FPCs, even small concentration drops slow etching and damage substrates. We test solution concentration (ferric chloride: 39-41Be°, cupric chloride: 190-210g/L) every 20 minutes via titration, adding regenerated solution to maintain consistency.

Substrate Compatibility for High-Flex FPCs: FPCs used in wearables require repeated bending—we avoid high temperatures (capped at 43℃) and use low-etch-rate solutions for these boards to prevent PI substrate brittleness. We also use Teflon racks to hold FPCs during etching, minimizing mechanical stress on flex sections.

Safety in Acidic Etching Environments: Our facilities feature acid mist extraction systems (removes 99% of fumes) and acid-resistant equipment (PVDF pipes, PP tanks) to protect operators and machinery. All staff receive FPC-specific etching training—critical for handling delicate PI substrates.

Partner with Huaruixin for Your FPC & PCB Needs

Whether you need high-precision FPC for medical devices, Rigid-Flex Boards for automotive electronics, or PCB for consumer tech, Shenzhen Huaruixin Electronics delivers etching excellence tailored to your project. Our FPC-focused processes ensure consistent quality, while our SEO-optimized manufacturing capabilities meet global standards.

To learn more about FPC etching process, PCB etching solutions, or to discuss your project:

Visit our website: www.hrxfpc.com (your source for FPC & PCB industry insights)

Email our team: sales@hrxfpc.com (free FPC etching consultation available)

We’re committed to helping you build reliable, high-performance FPCs and PCBs—let’s collaborate to bring your designs to life!

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP