Search

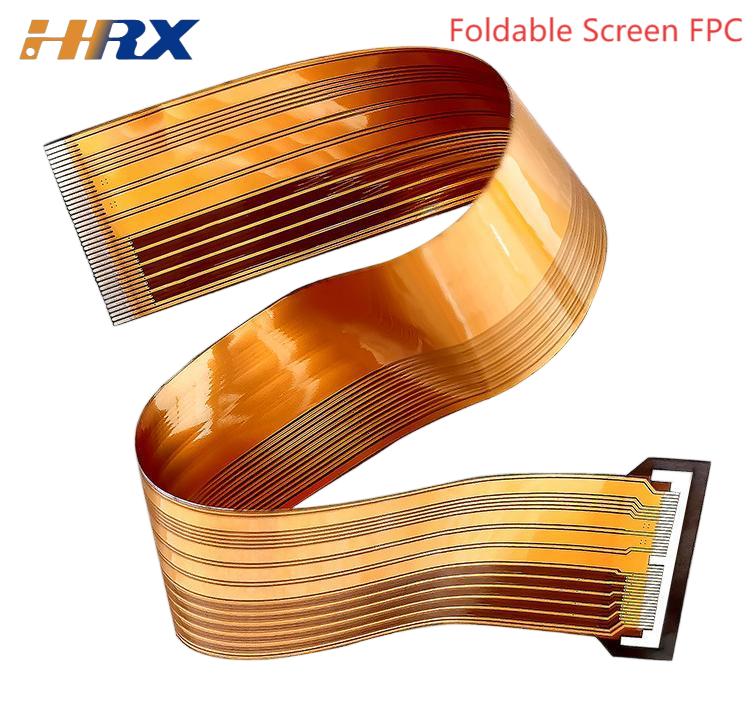

Foldable Screen FPC: Key Characteristics, Manufacturing Essentials for Flexible PCB Durability

- Aug 11,2025

-

Share

In the rapidly evolving consumer electronics landscape, foldable devices have emerged as a transformative innovation, with foldable displays serving as their technological cornerstone. At the heart of these displays’ seamless functionality lies the Foldable Screen Flexible Printed Circuit (FPC)—a specialized component engineered to withstand repeated bending while ensuring uncompromised performance. As a leading ODM/OEM manufacturer of FPC, PCB, and rigid-flex printed boards, Shenzhen Huaruixin Electronics Co., Ltd. leverages its state-of-the-art manufacturing base and decades of expertise to master the complexities of foldable screen FPC production. This blog explores the unique traits of foldable screen FPC, critical manufacturing considerations, and why choosing the right partner matters.

Unique Characteristics of Foldable Screen FPC: Beyond Standard Flexible Circuits

Foldable screen FPC is a marvel of engineering, distinct from conventional FPCs due to its ability to endure dynamic mechanical stress. Its defining features include:

Superior Folding Endurance & Fatigue Resistance

Unlike standard FPCs designed for static or minimal bending, foldable screen FPC must withstand 200,000+ folding cycles—a benchmark set by leading device manufacturers. This is achieved through advanced material science: high-grade polyimide (PI) substrates with enhanced tensile strength form the core, while thin-gauge electrolytic copper foils (12μm–18μm) minimize brittleness during repeated flexion. The folding zone, often designed with a “hinge-like” structure, undergoes rigorous finite element analysis (FEA) to reduce stress concentration, ensuring long-term durability without conductor cracking or delamination.

Ultra-Fine Line Geometry & High-Density Interconnects

Foldable displays demand compact, high-performance FPCs to integrate touch sensors, display drivers, and power lines. Foldable screen FPC features ultra-fine traces with line widths/spacings as low as 30μm–50μm, enabled by precision manufacturing techniques like laser direct imaging (LDI). This high-density interconnect (HDI) capability ensures seamless signal transmission between the foldable panel and device mainboard, supporting 4K/8K display resolutions and high refresh rates critical for user experience.

Optimized Signal Integrity (SI) & Impedance Control

Dynamic folding introduces signal distortion risks, making signal integrity (SI) a top priority. Foldable screen FPC incorporates controlled differential pair routing and impedance matching (typically 50Ω or 100Ω) to minimize crosstalk and signal loss. Shielding layers, often made of aluminum or copper, further isolate sensitive high-speed signals (e.g., MIPI D-PHY) from electromagnetic interference (EMI), ensuring stable data transmission even during continuous folding.

Thin-Film Construction & Material Compatibility

To align with the slim design of foldable devices, foldable screen FPC adopts a thin-film structure with total thicknesses as low as 0.08mm–0.12mm. This is achieved by laminating ultra-thin PI substrates with low-profile coverlay (instead of traditional solder mask) and using adhesive-free copper-clad laminates (CCL) to reduce bulk. Additionally, materials are selected for compatibility with display modules—adhesives with controlled peel strength prevent delamination from glass or OLED panels, while heat-resistant substrates withstand solder reflow temperatures during assembly.

Critical Manufacturing Considerations for Foldable Screen FPC Quality

Producing foldable screen FPC requires precision engineering and strict process control. Shenzhen Huaruixin Electronics prioritizes these key areas to ensure reliability:

Advanced Material Sourcing & Validation

The foundation of high-quality foldable screen FPC lies in premium raw materials. We source high-purity PI films (e.g., DuPont Kapton®) with stable dielectric properties and annealed copper foils to enhance flexibility. Every batch undergoes rigorous validation, including thermal stability testing (-40℃ to 125℃) and mechanical strength checks, to ensure compliance with IPC-4202 standards for flexible base materials.

Precision Circuit Fabrication with LDI & AOI

Ultra-fine traces demand cutting-edge fabrication. Our facilities employ high-resolution LDI systems (5μm positioning accuracy) for pattern transfer, ensuring trace fidelity even at 30μm line/space. Post-etching, automated optical inspection (AOI) with AI-powered defect detection identifies micro-cracks, undercuts, or short circuits—critical for preventing field failures. For complex designs, we integrate sequential lamination to achieve multi-layer HDI structures without compromising flexibility.

Folding Zone Optimization & Stress Relief

The folding zone is engineered using laser ablation for clean edge profiling, reducing stress points that cause fatigue. We apply controlled thermal curing during lamination to minimize residual stress, a key factor in preventing substrate warpage. Folding endurance tests (per IPC-9702) validate performance, with our FPCs consistently exceeding 200,000 cycles under accelerated conditions.

Rigorous Reliability & Environmental Testing

Beyond mechanical performance, foldable screen FPC must withstand harsh environments. Our testing regimen includes:

Temperature cycling (-40℃ to 85℃, 1,000 cycles) to test thermal stability;

Moisture resistance (85℃/85% RH, 500 hours) to prevent corrosion;

Solderability testing (IPC-J-STD-002) to ensure robust assembly;

Impedance continuity checks during folding to validate signal integrity.

Quality Management & Certifications

Adhering to ISO 9001:2015 standards, our manufacturing process is governed by strict quality management systems (QMS). Real-time process monitoring, from material incoming to final inspection, ensures traceability. Statistical process control (SPC) is applied to critical parameters like etching depth and lamination pressure, minimizing variability and ensuring consistent output.

Partner with Huaruixin for Premium Foldable Screen FPC Solutions

As a trusted FPC&PCB&rigid-flex printed board ODM/OEM manufacturer, Shenzhen Huaruixin Electronics combines technical expertise with large-scale production capabilities to deliver foldable screen FPCs that meet the most demanding requirements. Whether you need custom designs for foldable phones, tablets, or wearables, our engineering team collaborates closely with clients to optimize FPC performance, from material selection to prototyping and mass production.

Ready to elevate your foldable device project? Contact us today for tailored solutions. For more insights on flexible PCB technology, visit our website: www.hrxfpc.com. Email us at sales@hrxfpc.com to discuss your needs—we’re here to support your innovation journey with reliable, high-performance foldable screen FPC.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP