Search

Flexible Circuit Board Manufacturing: Expert Insights & OEM/ODM Solutions by Huaruixin Electronics

- Sep 03,2025

-

Share

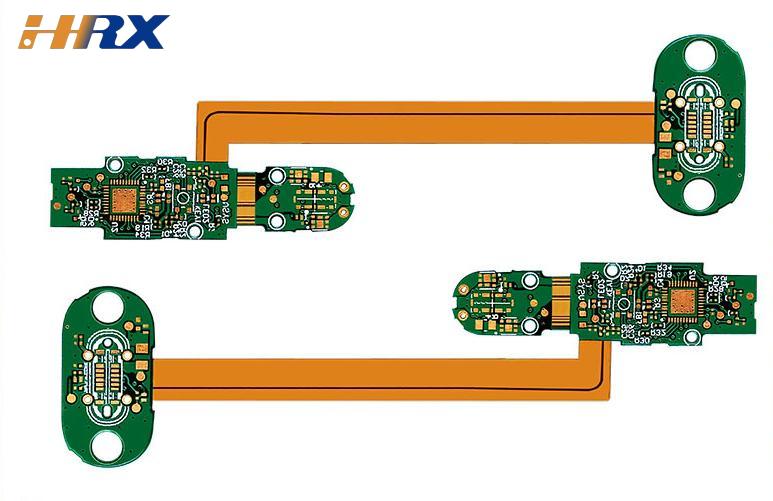

In the era of miniaturized, flexible electronics—from foldable smartphones to wearable tech and automotive IoT sensors—Flexible Printed Circuits (FPCs) have become irreplaceable. However, high-quality FPC production demands mastery of flexible circuit board manufacturing processes, precision material selection, and scalable production capabilities. As a global leader in FPC OEM/ODM services, Shenzhen Huaruixin Electronics Co., Ltd. specializes in end-to-end FPC design, PCB fabrication, and Rigid-Flex Printed Board manufacturing—blending technical expertise with large-scale production to meet global clients’ diverse needs. Below, we break down the critical stages of FPC manufacturing, share Huaruixin’s industry-proven practices, and highlight how we deliver reliable, cost-effective flexible circuit solutions.

Key Stages of FPC Manufacturing: From Raw Materials to Finished Products

Successful flexible circuit board production hinges on strict process control and alignment with application requirements. Huaruixin’s workflow adheres to international standards (IPC-6012, IPC-2223) and integrates advanced technologies to ensure consistency. Here’s a detailed breakdown:

1. Pre-Production: Material Selection & Substrate Preparation

The foundation of high-performance FPCs lies in FPC material selection—a step where Huaruixin’s engineering team tailors choices to client use cases:

Flexible Substrates: Primary material is Polyimide (PI) film (25μm, 50μm, 75μm thickness), chosen for its excellent thermal resistance (200℃+), chemical stability, and flexibility—ideal for automotive electronics and industrial devices. For cost-sensitive, low-temperature applications (e.g., basic consumer gadgets), we use PET film (polyethylene terephthalate).

Copper Foils: Two types to match flexibility needs:

Electrodeposited (ED) Copper Foil (12–70μm): Cost-effective for standard FPCs with minimal bending requirements.

Rolled Annealed (RA) Copper Foil (9–35μm): Ultra-flexible, with high fatigue resistance—critical for foldable FPCs (e.g., foldable phone hinges) that undergo thousands of bending cycles.

Adhesives & Protective Layers: Epoxy-based adhesives or acrylic adhesives for bonding substrates and copper foils; Coverlay (CVL) (PI film + adhesive, 25–50μm) to protect circuits from oxidation, moisture, and mechanical damage.

Post-selection, Huaruixin’s substrate pretreatment process ensures optimal adhesion:

Ultrasonic Cleaning: Removes dust, oil, and contaminants from PI films/copper foils to prevent lamination defects.

Chemical Roughening: Uses chromic acid treatment to create micro-rough surfaces on substrates—enhancing dry film and adhesive bonding (avoids FPC trace lifting in later stages).

Precision Drying: Oven drying at 80–120℃ eliminates moisture, a key step to prevent FPC lamination bubbles during heat pressing.

For high-reliability projects (e.g., medical devices), we use adhesive-free FPC substrates—bonded via high-temperature (250℃+) and high-pressure (30–50kg/cm²) lamination, leveraging molecular adhesion between copper and PI to eliminate adhesive-related failure risks.

2. Circuit Fabrication: Precision Pattern Transfer & Etching

The FPC circuit fabrication stage is where design blueprints become physical conductive paths—requiring micron-level accuracy. Huaruixin’s process includes:

a. Dry Film Lamination

We use photosensitive dry film (composed of polyester film, photosensitive resin layer, and PE protective film) to mask desired copper traces. Our automated FPC laminating machines preheat substrates to 40–60℃ (optimizing film adhesion) and apply uniform pressure—ensuring no bubbles or wrinkles (critical to avoid etching etching unevenness later).

b. UV Exposure

Using FPC photomasks (customized to client circuit designs), we expose the dry film to UV light (50–100mJ/cm², 10–30 seconds). The UV light cures the exposed dry film (cross-linking the resin), while unexposed areas remain soluble—this is the core of FPC pattern transfer.

c. Development & Etching

Alkaline Development: Uses 1–2% sodium carbonate solution (25–30℃, 60–120 seconds) to dissolve unexposed dry film, revealing copper areas to be etched.

Acidic Etching: Employs ferric chloride (FeCl₃) or cupric chloride (CuCl₂) solutions (40–50℃) to remove excess copper. Huaruixin uses spray etching equipment with adjustable pressure and temperature—controlling etching speed (1–2μm/min) to prevent FPC trace undercutting (over-etching) or residual copper (short circuits).

d. Dry Film Stripping

Post-etching, a 3–5% sodium hydroxide solution (50–60℃, 30–60 seconds) strips cured dry film—exposing clean, precise copper traces. We perform 100% visual inspection here to catch defects like FPC trace breakage or copper slag.

3. Circuit Protection: Coverlay Lamination & Solder Mask Application

Exposed copper traces are prone to oxidation and damage, so FPC protection is vital. Huaruixin offers two tailored solutions:

a. Coverlay Lamination (For High Flexibility)

Ideal for flexible FPCs (e.g., wearable tech), this process involves:

Coverlay Punching: Laser-cutting "windows" in CVL to expose FPC pads (for component soldering) and connectors.

Pre-Pressing: Aligning CVL with substrates and applying 10–20kg/cm² pressure at 80–100℃ (10–20 seconds) to fix positioning.

Thermal Curing: Heat-pressing at 180–200℃ (30–60 minutes, 30–50kg/cm²) to fully cure the adhesive—creating a bubble-free, durable bond that resists bending fatigue.

b. Solder Mask Printing (For Cost-Effective Stability)

For rigid-flex PCBs or simple FPC designs, we use liquid solder mask (similar to PCB green oil):

Screen Printing: Precision printing to cover all areas except pads/connectors.

Pre-Drying: Oven curing at 70–80℃ (10–20 minutes) to remove solvents.

UV Curing & Development: UV exposure (curing the mask) and alkaline development (removing unexposed mask) follow, with final thermal curing at 150–180℃ (60–90 minutes) for hardness.

4. Post-Processing: Reinforcement, Drilling & Surface Finish

To enhance functionality and reliability, Huaruixin adds critical post-processing steps:

a. Reinforcement Board Lamination

FPC reinforcement is essential for high-stress areas (e.g., connector ports, component mounting zones) that need rigidity. We use PI reinforcement boards, FR4 reinforcement plates, or metal reinforcement sheets (aluminum, stainless steel) — laminated via adhesive bonding (120–150℃, 20–30kg/cm², 20–30 minutes) to prevent FPC bending damage during assembly and use.

b. FPC Drilling

For multi-layer FPCs or designs requiring mounting holes:

Laser Drilling: Used for micro-vias (≥0.1mm) — ideal for high-density FPCs (e.g., smartphone cameras) due to its precision.

Mechanical Drilling: For larger holes (≥0.2mm, e.g., positioning holes) — equipped with CNC drilling machines for accuracy.

Post-drilling, we use high-pressure air to remove drill debris—preventing plating issues in via holes.

c. Surface Finish (For Solderability & Corrosion Resistance)

Huaruixin offers three industry-standard FPC surface finishes to match application needs:

Surface Finish Type Process Details Key Advantages Ideal Applications

ENIG (Electroless Nickel Immersion Gold) 2–5μm nickel layer + 0.05–0.1μm gold layer High solderability, low contact resistance, excellent corrosion resistance High-precision IC pads, RF connectors, medical FPCs

HASL (Hot Air Solder Leveling) Immersion in molten tin + hot air leveling (5–15μm tin layer) Cost-effective, strong solder joint reliability General components (resistors, capacitors), consumer electronics FPCs

OSP (Organic Solderability Preservative) Thin organic film (0.1–0.3μm) on copper surface Lead-free, no space occupation, preserves fine-pitch traces High-density FPCs, lead-free compliant devices

5. Final Shaping & Quality Assurance

a. FPC Contour Cutting

We use two methods to trim FPCs to final dimensions:

Die Cutting: For high-volume production (100,000+ units) — custom steel dies punch FPCs quickly, with edge tolerance ±0.05mm.

Laser Cutting: For complex shapes (e.g., irregular FPCs) or small batches — precision ±0.01mm, no mechanical stress on circuits.

Post-cutting, we deburr edges to eliminate FPC burrs (which cause short circuits during assembly).

b. Comprehensive Quality Testing

Huaruixin’s FPC quality control system meets ISO 9001 and IATF 16949 standards, with 100% inspection at key stages:

AOI Inspection: Automated Optical Inspection systems scan for micro-defects (trace cracks, pad misalignment, coverlay bubbles) at μm-level precision.

Electrical Testing:

Open/Short Test: Probe stations verify circuit continuity (no open circuits) and isolate unintended connections (no short circuits).

Impedance Testing: Ensures FPC characteristic impedance (50Ω, 75Ω, etc.) matches design specs — critical for signal integrity in high-speed FPCs.

Dielectric Withstand Test: Applies 500V AC to test insulation between traces and substrate (no leakage).

Reliability Testing (sampling, per IPC standards):

Bending Test: 180° repeated bending (1,000–10,000 cycles) to validate flexibility (no trace breakage).

High-Low Temperature Test: Exposure to -40℃ (low) and 125℃ (high) for 1,000 hours — checks material stability.

Humidity Test: 40℃, 90% relative humidity for 500 hours — prevents coverlay delamination.

Huaruixin’s FPC OEM/ODM Advantages: Why Global Clients Choose Us

As a top FPC manufacturer in Shenzhen, Huaruixin stands out for its ability to turn technical expertise into client-centric solutions. Here’s what makes our FPC OEM/ODM services unique:

1. End-to-End Design & Engineering Support

Our in-house R&D team offers FPC Design for Manufacturability (DFM) services — optimizing client designs to reduce production costs and lead times (typically 20–30% faster than industry averages). We support custom flexible circuit designs for diverse industries:

Automotive FPCs: IATF 16949 compliant, with high-temperature resistance (up to 150℃) and vibration resistance for engine control units (ECUs) and infotainment systems.

Medical FPCs: Biocompatible materials, ENIG surface finish, and strict sterility compliance for wearable monitors and diagnostic devices.

Consumer Electronics FPCs: Ultra-thin (≤0.1mm) and foldable designs for smartphones, tablets, and smartwatches.

2. Large-Scale, Automated Production Capacity

Huaruixin’s 10,000㎡ manufacturing base in Shenzhen is equipped with 20+ automated production lines (lamination, etching, drilling, testing) — enabling monthly output of 500,000+ FPC units and 100,000+ rigid-flex PCBs. We handle both:

Prototype FPCs: Fast turnaround (3–5 days) for small batches (10–100 units) — ideal for R&D phases.

Mass Production FPCs: Stable yield rate (≥98%) for high-volume orders — supported by lean manufacturing processes.

3. Global Compliance & Customization

We adhere to global regulatory standards (RoHS 2.0, REACH, UL 94 V-0) and offer fully customized solutions:

Material Customization: Choose substrates, copper foils, and surface finishes to match your application.

Process Customization: Tailor lamination, etching, and testing parameters for specialized needs (e.g., high-frequency FPCs for 5G devices).

Partner with Huaruixin for Your FPC/PCB Projects

If you’re searching for a reliable FPC manufacturer with proven expertise in flexible circuit board manufacturing, PCB fabrication, and rigid-flex printed board OEM/ODM services—look no further than Shenzhen Huaruixin Electronics.

Whether you need:

Custom foldable FPC design for a new wearable device;

High-volume automotive FPC production compliant with IATF 16949;

Technical support for high-density FPC development;

We’re ready to collaborate.

Explore Industry Knowledge: Visit our website www.hrxfpc.com for FPC technical guides, case studies, and latest manufacturing trends.

Request a Quote or Consultation: Email our sales team at sales@hrxfpc.com — we’ll respond within 24 hours with tailored solutions, samples, or technical advice.

At Huaruixin, we don’t just manufacture FPCs—we deliver flexible circuit solutions that power your innovation.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP