Search

Exploring Key Factors of Premium FPCs and Showcasing Shenzhen Huaruixin Electronics Co., Ltd.

- May 21,2025

-

Share

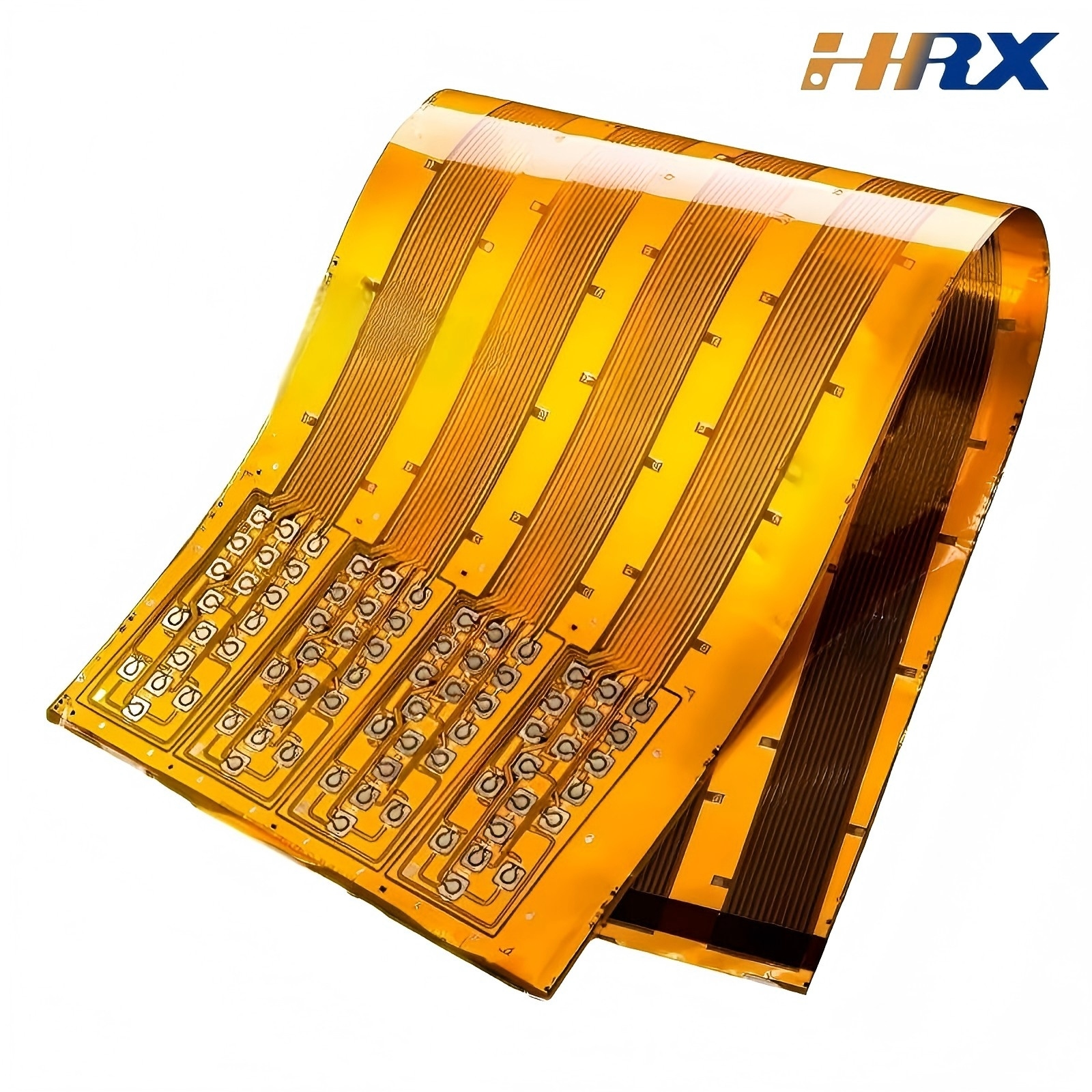

Flexible Printed Circuits (FPCs) have become the backbone of modern electronics, powering innovations in smartphones, wearables, automotive systems, and medical devices. As a critical component requiring precision and reliability, the "best" FPCs must meet stringent technical and operational standards. This blog delves into the essential factors defining top-tier FPCs and highlights how Shenzhen Huaruixin Electronics Co., Ltd. excels as a global ODM/OEM provider in the FPC, PCB, and Rigid-Flex Printed Board domains.

Key Factors of Exceptional FPCs

1.Material Excellence

High-quality base materials (e.g., polyimide, polyester) ensure flexibility, thermal stability, and resistance to environmental factors like moisture and chemicals.

Example: Advanced FPCs for automotive applications require materials compliant with IPC-6013 standards and capable of withstanding extreme temperatures (-40°C to +150°C).

2.Design Precision

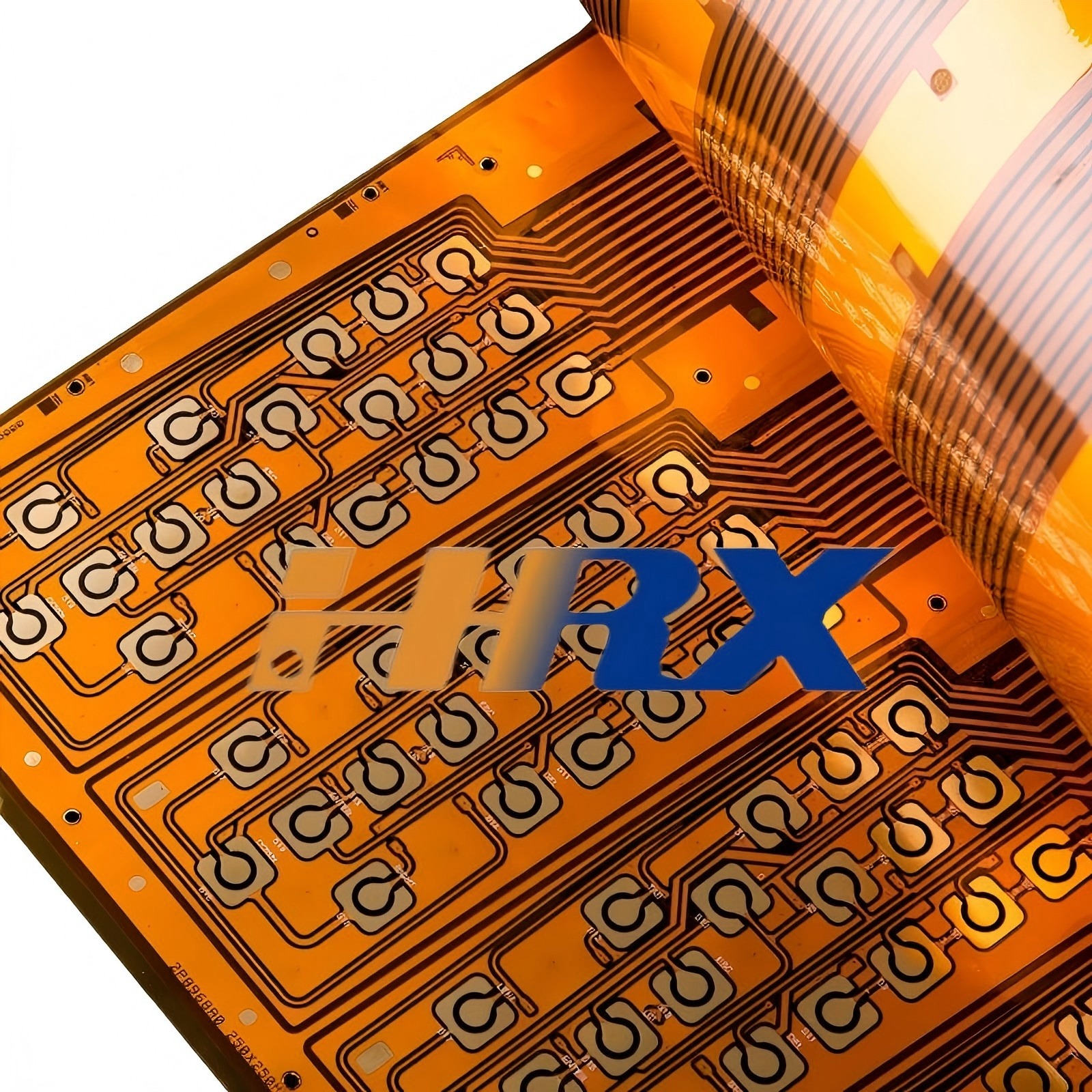

Miniaturization: Ultra-fine line widths (≤50μm) and spacing for high-density interconnects (HDIs) in portable devices.

Layer Complexity: Multi-layer FPCs (e.g., 2-30 layers) with precise registration for signal integrity in high-frequency applications like 5G modules.

3.Manufacturing Capability

Advanced Processes: Laser drilling for microvias, electroplating for uniform conductivity, and automated optical inspection (AOI) for defect detection.

Compliance: Adherence to ISO 9001, IPC-A-600, and RoHS/REACH standards to ensure consistency and global market eligibility.

4.Reliability and Testing

Rigorous Quality Control: Bend testing (≥100,000 cycles), thermal shock testing, and impedance matching to guarantee performance under stress.

Example: FPCs for medical implants must pass biocompatibility tests (e.g., USP Class VI) and long-term durability assessments.

5.Customization and Scalability

Tailored Solutions: Design-for-Manufacturing (DFM) expertise to translate client concepts into cost-effective, scalable products.

Volume Flexibility: Capability to handle prototyping (low-volume) and mass production (high-volume) efficiently.

Shenzhen Huaruixin Electronics: A Leader in FPC Innovation

As a vertically integrated provider with a large-scale manufacturing base, Shenzhen Huaruixin combines technical prowess with customer-centric solutions. Here’s how they embody the benchmarks of excellence:

1. Technical Expertise & Advanced Facilities

Design Capabilities: A dedicated R&D team proficient in CAD tools (Altium, PADS) and DFM/DFA methodologies, enabling rapid prototyping for complex Rigid-Flex boards.

Manufacturing Strengths:

State-of-the-art production lines with precision etching equipment (line width tolerance: ±10%).

In-house testing labs for AOI, X-ray inspection, and environmental stress screening (ESS).

Example: Their 12-layer Rigid-Flex board for a leading automotive OEM achieved 100% compliance with IPC-6012 Class 3 standards, ensuring reliability in ADAS systems.

2. Quality Assurance & Compliance

Certified to ISO 9001:2015,and IPC-6012, Huaruixin maintains strict traceability through barcode systems and statistical process control (SPC).

RoHS/REACH-compliant materials ensure products meet EU/US environmental regulations, critical for global clients in consumer electronics and industrial sectors.

3. Customer-Centric Solutions

ODM/OEM Services: End-to-end support from schematic design to mass production, with flexible MOQs (as low as 10 pieces for prototypes).

Industry Applications:

Consumer Electronics: Ultra-thin (0.1mm) FPCs for foldable smartphones, tested to 200,000 bend cycles.

Medical Devices: Biocompatible FPCs for wearable health monitors, passing USP Class VI and cytotoxicity tests.

Aerospace: High-reliability Rigid-Flex boards for avionics, certified to MIL-P-55110 standards.

4. Global Reach & Partnerships

With a footprint spanning North America, Europe, and APAC, Huaruixin serves Fortune 500 companies and emerging startups alike. Their 24/7 technical support and average lead time of 7-15 days for prototypes demonstrate commitment to client agility.

Conclusion

The "best" FPCs are a fusion of material science, engineering precision, and manufacturing rigor. Shenzhen Huaruixin Electronics Co., Ltd. exemplifies this by combining cutting-edge facilities, stringent quality systems, and customer collaboration to deliver solutions that drive innovation across industries. Whether you need a flexible board for a next-gen gadget or a rugged Rigid-Flex design for industrial use, Huaruixin’s expertise ensures reliability at scale.

Connect with Shenzhen Huaruixin Today:

Visit their website: www.hrxfpc.com

Email: sales@hrxfpc.com

Explore how their team can transform your FPC/PCB requirements into reality.

Stay ahead in electronics manufacturing—partner with a provider that prioritizes excellence at every layer.

This blog is sponsored by Shenzhen Huaruixin Electronics Co., Ltd., a trusted name in advanced printed circuit solutions.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP