Search

Equipment Maintenance and Calibration in FPC, PCB, and Rigid - Flex Board Sectors: Processes, Standards, and Unique Advantages of Shenzhen Huaruixin Electronics

- Sep 19,2025

-

Share

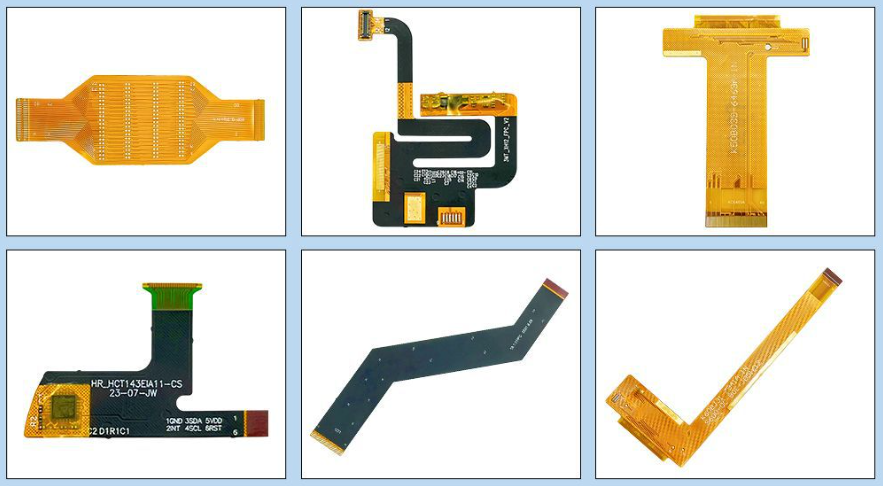

As a leading global ODM/OEM manufacturer in the FPC (Flexible Printed Circuit), PCB (Printed Circuit Board), and rigid - flex board sectors, Shenzhen Huaruixin Electronics Co., Ltd. stands out with its remarkable capabilities. We operate a large - scale manufacturing base, engage deeply in product design and development, and have successfully obtained certifications such as the GB/T19001 - 2016/ISO 9001:2015 Quality Management System Certification, IAF International Accreditation, and CNAS National Accreditation. These certifications underpin the stability and reliability of our products and services, enabling us to maximize the value of cooperation for our global clients. From the perspective of a professional equipment manufacturing manager, this blog comprehensively details our equipment maintenance and calibration processes, standards, unique features, and key considerations, aiming to provide in - depth insights for industry professionals and those interested in FPC, PCB, and rigid - flex board manufacturing.

1. Equipment Maintenance Processes

1.1 Pre - Maintenance Preparation

Conduct a comprehensive assessment of equipment status. This involves a detailed review of equipment operation records, fault history, and current performance parameters. By analyzing these data, potential issues can be identified in advance, allowing for more targeted maintenance planning. For example, if an FPC cutting machine has shown a gradual decrease in cutting accuracy over time, this information can be used to prioritize the calibration of relevant components during maintenance.

Prepare essential maintenance tools, spare parts, and technical documents. High - precision measuring tools are crucial for accurate calibration, and having the right spare parts on hand ensures that any faulty components can be replaced promptly. Technical documents, such as equipment manuals and maintenance procedures, serve as a guide for maintenance personnel, ensuring that they follow the correct steps and safety protocols.

Assign professional maintenance personnel with relevant qualifications and experience. Our team of maintenance engineers is well - trained in handling FPC, PCB, and rigid - flex board equipment. They undergo regular training to keep up with the latest technological advancements in the industry. Before starting any maintenance work, pre - maintenance training is provided to familiarize them with the specific tasks and safety requirements for the equipment at hand.

1.2 Routine Maintenance

Perform daily inspections on equipment. This includes a visual check of the equipment's appearance for any signs of damage or wear, such as scratches on the surface of a PCB drilling machine. The tightness of fasteners is also inspected to prevent any parts from becoming loose during operation. Moving parts are checked for proper lubrication to reduce friction and extend their lifespan. Electrical systems are examined to ensure normal operation, and any abnormal noises or fluctuations in power consumption are noted. All inspection results are recorded in detail for future reference.

Conduct weekly or monthly preventive maintenance according to the equipment maintenance plan. For FPC laminating machines, this may involve cleaning the laminating rollers to remove any residue that could affect the quality of the laminated FPC. Worn - out parts, such as filters in air - cooling systems or belts in conveyor systems, are replaced. Measuring instruments used in the production process, like thickness gauges for FPC, are calibrated to ensure accurate measurements. After the preventive maintenance is completed, the equipment is tested to ensure that it operates smoothly. All maintenance activities and test results are updated in the equipment maintenance records.

1.3 Fault Maintenance

When a fault occurs in the equipment, maintenance personnel respond promptly. They conduct on - site investigations, carefully observing the fault symptoms. For instance, if an FPC soldering machine experiences inconsistent soldering quality, the temperature control system, solder supply mechanism, and soldering tip condition are all examined. Based on the equipment's technical data and the observed symptoms, the cause of the fault is identified.

A fault repair plan is then developed. This plan includes determining the repair steps, such as whether it requires replacing a specific component or adjusting the equipment's parameters. The required spare parts are identified, and an estimate of the repair time is made. In some cases, the repair plan may need to be approved by a supervisor or relevant department to ensure that it aligns with the overall production schedule.

The repair plan is implemented following strict safety procedures. Faulty parts are replaced with high - quality spares, and equipment parameters are adjusted precisely. During the repair process, safety is of utmost importance. Maintenance personnel wear appropriate personal protective equipment, and the equipment is isolated from power sources to prevent accidents.

After the repair is completed, a comprehensive test of the equipment is carried out. This includes running sample production processes to verify that the fault has been completely eliminated and that the equipment's performance meets the required standards. The repair process and results are thoroughly recorded in the equipment maintenance records for future reference and to track the equipment's maintenance history.

2. Equipment Calibration Standards

2.1 Compliance with International and National Standards

Our equipment calibration work strictly adheres to international standards such as ISO/IEC 17025 (General Requirements for the Competence of Testing and Calibration Laboratories). This standard ensures that our calibration processes are carried out with the highest level of accuracy and reliability. We also comply with national standards relevant to the FPC, PCB, and rigid - flex board industries, ensuring that our products and services meet the regulatory requirements of different regions. By following these standards, we establish a solid foundation for the traceability of calibration results.

We have established a calibration traceability system. All calibrated measuring instruments and equipment can be traced back to national or international measurement standards through a chain of calibrations. This traceability ensures that the accuracy of our equipment calibration can be verified and compared with recognized standards, providing confidence in the quality of our products and services.

2.2 Calibration Parameters and Tolerances

For different types of equipment in the FPC, PCB, and rigid - flex board manufacturing, we have defined detailed calibration parameter lists. In an FPC etching machine, calibration parameters may include the etching rate, the uniformity of the etching process, and the dimensional accuracy of the etched patterns. In a PCB drilling machine, parameters such as drilling position accuracy, hole diameter tolerance, and the perpendicularity of the drilled holes are crucial.

Strict calibration tolerances are set based on the equipment's technical specifications and the requirements of the production process. For example, in the production of high - density FPC, the tolerance for the width of conductive lines may be set within a very narrow range, such as ±0.05 mm. If the calibration results exceed these tolerances, the equipment is adjusted or repaired immediately until it meets the specified requirements. This ensures that the final products meet the high - quality standards expected by our customers.

2.3 Calibration Cycle and Documentation

The calibration cycle of equipment is determined based on factors such as equipment usage frequency, working environment, and stability. Equipment that is used frequently or operates in harsh environments, such as FPC manufacturing equipment in a high - humidity production area, may require more frequent calibration, typically once a month or once a quarter. General - purpose equipment with a relatively stable working environment may have a longer calibration cycle, such as once every six months or once a year.

Complete calibration documentation is maintained. This includes calibration certificates issued by qualified calibration institutions or our internal calibration laboratory, which meets the relevant standards. Calibration records detail the calibration process, including the values measured before and after calibration, any adjustments made to the equipment, and the environmental conditions during calibration. Calibration reports summarize the overall results and provide an assessment of whether the equipment meets the calibration requirements. These documents are essential for tracking the calibration history of equipment and demonstrating compliance with quality management systems.

3. Unique Advantages in Equipment Maintenance and Calibration

3.1 Integration of Maintenance and Quality Management Systems

Leveraging our GB/T19001 - 2016/ISO 9001:2015 Quality Management System, we seamlessly integrate equipment maintenance and calibration into the overall quality management process. Every step of maintenance and calibration, from the initial planning to the final verification of results, is subject to strict quality control. For example, the selection of maintenance personnel, the procurement of spare parts, and the calibration procedures are all evaluated and approved within the framework of the quality management system.

Through the quality management system, regular audits and evaluations of the equipment maintenance and calibration work are conducted. This allows us to identify any potential issues or areas for improvement in a timely manner. Corrective and preventive actions are then implemented to continuously enhance the quality of maintenance and calibration, ensuring that our equipment always operates at its optimal level and that our products meet the highest quality standards.

3.2 Professional Technical Team and Advanced Maintenance Equipment

We have assembled a team of highly professional and experienced maintenance and calibration engineers. These engineers have received systematic training in FPC, PCB, and rigid - flex board equipment technology. They hold relevant professional certifications, such as those related to precision equipment maintenance and calibration. Their in - depth knowledge and practical skills enable them to handle complex equipment issues effectively.

We invest significantly in advanced maintenance tools and calibration equipment. High - precision measuring instruments, such as laser - based alignment tools for PCB drilling machines, ensure accurate calibration of equipment parameters. Computer - aided maintenance systems are used to monitor equipment performance in real - time, predict potential failures, and schedule maintenance tasks more efficiently. These advanced tools and equipment not only improve the accuracy and efficiency of maintenance and calibration work but also contribute to the overall quality and productivity of our manufacturing processes.

3.3 Customized Maintenance and Calibration Solutions

Recognizing the diverse needs of our customers, we offer customized maintenance and calibration solutions. We engage in in - depth communication with customers to understand their specific equipment usage scenarios, production requirements, and quality expectations. Based on this understanding, we develop tailored maintenance plans and calibration standards for their equipment.

For customers with special requirements, such as those in industries with strict regulatory compliance or high - precision product requirements, we provide on - site maintenance and calibration services. We also establish long - term cooperative relationships with our customers, offering continuous technical support and after - sales service. This personalized approach ensures that our customers' equipment operates smoothly and efficiently, meeting their unique business needs.

4. Key Considerations in Equipment Maintenance and Calibration

4.1 Safety First

Safety is our top priority in equipment maintenance and calibration work. We strictly abide by national safety regulations and our own enterprise - specific safety management systems. Maintenance personnel are required to wear appropriate personal protective equipment, including safety helmets, safety glasses, and anti - static gloves, depending on the nature of the work.

Before starting any maintenance or calibration work, the equipment's power supply is completely cut off, and energy isolation devices are locked to prevent accidental startup. Warning signs are prominently displayed to alert others in the area. All safety procedures are carefully followed to ensure the well - being of our maintenance personnel and to prevent any damage to the equipment.

4.2 Traceability of Calibration Results

The traceability of calibration results is of utmost importance for ensuring the accuracy and reliability of equipment. We ensure that all calibrated measuring instruments and equipment can be traced back to national or international measurement standards. When selecting calibration institutions, we only choose those with legal metrological verification qualifications and a good reputation in the industry.

All calibration certificates and relevant documents are carefully preserved, and a comprehensive calibration record system is established. This system allows for easy traceability and query of calibration results, providing evidence of the equipment's calibration status and compliance with standards. In case of any disputes or quality audits, the traceability of calibration results can be demonstrated clearly.

4.3 Timeliness of Maintenance and Calibration

Timely maintenance and calibration are essential for preventing equipment failures and ensuring the smooth operation of the production line. We strictly adhere to the established maintenance and calibration cycles. Skipping or delaying maintenance and calibration work without valid reasons can lead to increased equipment failures, reduced product quality, and potential production disruptions.

For equipment that shows abnormal performance or has potential faults, immediate action is taken to conduct maintenance and calibration. By addressing these issues promptly, we can prevent minor problems from escalating into major breakdowns, minimizing economic losses and maintaining the efficiency of our production processes.

4.4 Training and Skill Improvement of Maintenance Personnel

The technical skills of maintenance personnel directly impact the quality of equipment maintenance and calibration work. We regularly organize training programs for our maintenance team. These programs cover a wide range of topics, including the latest equipment technologies in the FPC, PCB, and rigid - flex board industries, updated maintenance procedures, and safety knowledge.

We encourage our maintenance personnel to participate in industry - wide technical exchanges and learning activities. This exposure to the latest industry trends and best practices helps them continuously improve their professional skills and comprehensive quality. By investing in the training and development of our maintenance team, we ensure that they are well - equipped to handle the challenges of maintaining and calibrating our advanced manufacturing equipment.

5. Contact Us

If you have project requirements in the FPC, PCB, or rigid - flex board sectors, and are looking for a professional manufacturer, Shenzhen Huaruixin Electronics Co., Ltd. is here to serve you. Please feel free to contact us at any time. For more industry - related knowledge and information about our products and services, you can visit our website: www.hrxfpc.com. You can also send an email to sales@hrxfpc.com for consultation. We look forward to communicating, learning, and collaborating with you.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP