Search

ENIG Surface Treatment for FPC/PCB: Advantages, Applications & Key Process Controls

- Sep 25,2025

-

Share

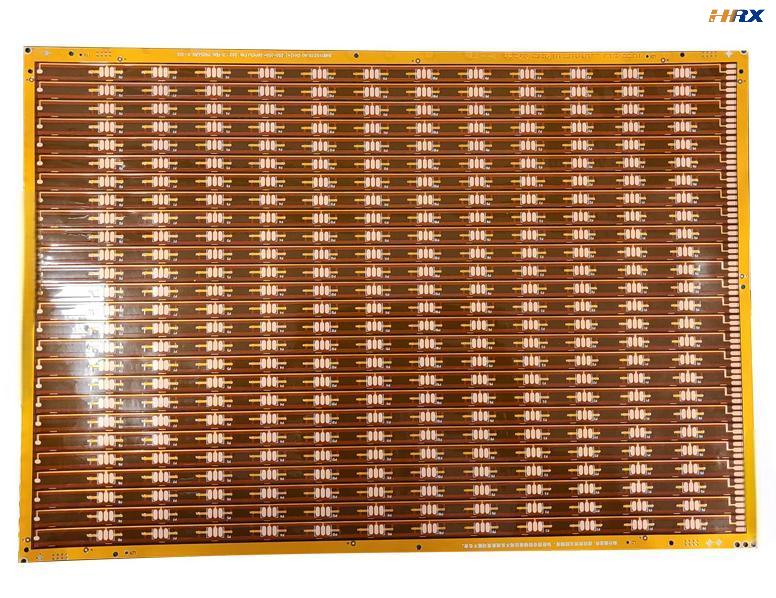

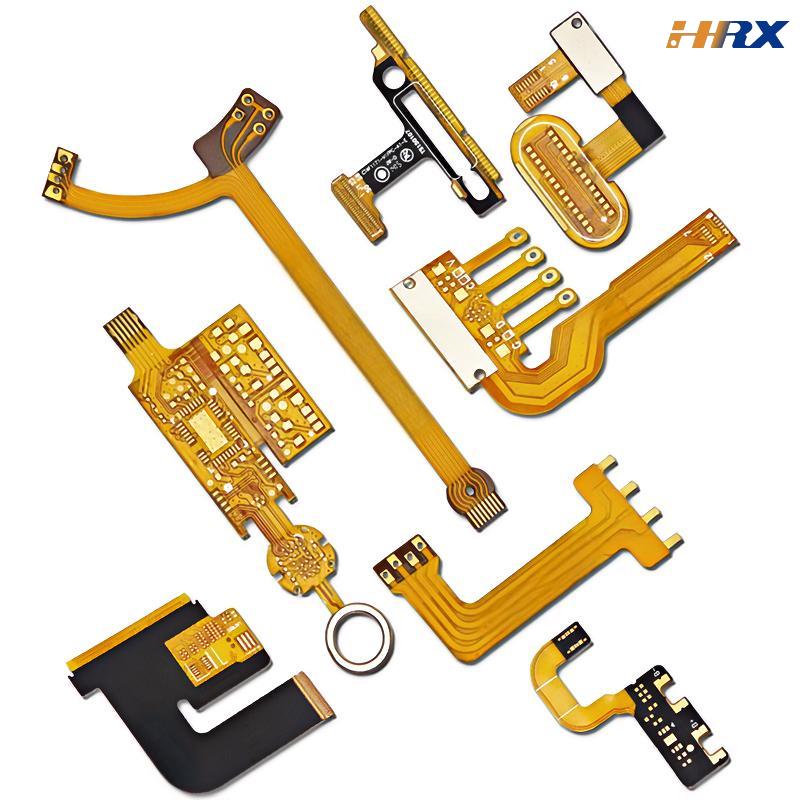

In flexible printed circuit (FPC), rigid printed circuit board (PCB), and rigid-flex board manufacturing, Electroless Nickel Immersion Gold (ENIG) stands as the gold standard for protecting exposed copper foils—including pads, connectors, and fine-pitch interfaces—from oxidation while enhancing solderability. As a global-leading ODM/OEM manufacturer specializing in FPC, PCB, and rigid-flex solutions, Shenzhen Huaruixin Electronics Co., Ltd. delivers premium ENIG processing backed by a large-scale production base, advanced R&D capabilities, and rigorous certifications (GB/T19001-2016/ISO 9001:2015, IAF international accreditation, and CNAS national recognition). Below is a comprehensive breakdown of ENIG’s value for FPC/PCB applications, optimized for precision and performance.

1. Core Advantages of ENIG for FPC/PCB Manufacturing

ENIG deposits a nickel-phosphorus alloy layer (2-5μm thick) on copper surfaces via chemical reduction, followed by a thin immersion gold layer (0.05-0.1μm) to create a dual-protective barrier. This structure delivers unmatched benefits for high-performance electronics:

Superior Oxidation & Corrosion Resistance: The dense gold layer blocks moisture and atmospheric contaminants, extending FPC/PCB shelf life to 12-18 months—far exceeding OSP’s 6-12 month window. Ideal for harsh environments in automotive and industrial applications.

Exceptional Solderability & Reflow Stability: The nickel underlayer promotes strong intermetallic compound (IMC) formation during soldering, while the gold layer ensures consistent wetting. ENIG supports over 10 reflow cycles, outperforming OSP’s 2-cycle limit, critical for complex SMT assembly.

Low & Stable Contact Resistance: Gold’s inherent conductivity maintains contact resistance ≤50mΩ, making it indispensable for high-frequency FPCs (e.g., 5G RF modules) where signal integrity is non-negotiable.

Uniform Coating on Flexible Substrates: Electroless plating ensures even coverage on FPC’s irregular surfaces and fine-pitch pads (≤0.1mm), avoiding thickness variations that compromise flexible electronics like wearables and foldable devices.

Compatibility with Gold Wire Bonding: Unlike HASL or OSP, ENIG enables reliable wire bonding for semiconductor packaging—essential for IC-integrated PCBs.

2. Limitations of ENIG & Mitigation Strategies

While ENIG excels in performance, it requires careful management of inherent challenges—an area where Huaruixin’s process expertise shines:

Higher Cost vs. Alternatives: ENIG costs $3.5-5.0 per m², compared to $0.8-1.2 for OSP. Huaruixin offsets this by offering selective ENIG (treating only critical pads like BGA areas) to balance performance and cost.

Black Pad Defect Risk: Brittle nickel oxide at the nickel-gold interface causes solder joint failure. Huaruixin mitigates this by controlling nickel phosphorus content (7-9%) and limiting gold immersion time to <10 minutes, with 100% MSA testing for P/Ni ratio compliance.

Thin Gold Layer Vulnerability: The 0.05-0.1μm gold layer resists minimal wear. For high-mating connectors, we recommend upgrading to ENEPIG (adding a 0.02-0.05μm palladium layer) to double lifespan.

Extended Processing Time: Electroless plating adds complexity, but Huaruixin’s automated production lines reduce lead times by 30% vs. industry averages.

3. Key Application Fields for ENIG-Coated FPC/PCB

ENIG’s precision makes it the top choice for industries demanding reliability. Huaruixin serves these high-growth sectors:

5G & Telecommunications: High-frequency FPCs in base stations and RF modules rely on ENIG’s low surface roughness (Ra 0.1-0.3μm) to minimize signal attenuation.

Automotive Electronics: ENIG meets AEC-Q100 standards, withstanding -40°C to 125°C operating temperatures. Used in ECUs, sensor modules, and infotainment rigid-flex boards.

Medical Devices: ENIG’s corrosion resistance passes ISO 13485 requirements for pacemakers, diagnostic equipment, and wearable health monitors.

Consumer Electronics: Foldable phones and wearables use ENIG-coated FPCs for their flexibility and solder joint reliability during repeated bending.

Industrial IoT: Miniaturized IoT sensors and control boards benefit from ENIG’s uniform coating on micro-pads and long-term environmental stability.

4. Critical Process Controls for ENIG Excellence

Huaruixin’s ISO 9001-certified quality system enforces strict protocols to ensure ENIG performance:

4.1 Pre-Treatment Precision

Surface Cleaning: Ultrasonic degreasing followed by sulfuric acid-hydrogen peroxide etching removes oxides and residues, ensuring nickel adhesion.

Micro-Etching: Acidic copper chloride creates a roughened surface to enhance plating adhesion, critical for flexible substrates.

4.2 Layer Thickness Management

Nickel Layer (2-5μm): Automated XRF monitoring prevents thin layers (which cause solder weakness) or excessive thickness (which cracks FPCs during bending).

Gold Layer (0.05-0.1μm): Titration testing ensures consistency—too thick risks black pads, too thin fails oxidation protection.

4.3 Post-Processing Inspection

Electrical Testing: Four-point probes verify contact resistance compliance.

Solderability Validation: IPC-9701 standard reflow tests and cross-sectional analysis of solder joints.

Environmental Compliance: RoHS/REACH-aligned chemical management and wastewater treatment for nickel/gold-containing solutions.

Partner with Huaruixin for Premium ENIG Solutions

Whether you need ENIG-coated FPCs for 5G devices, automotive PCBs, or medical equipment, Shenzhen Huaruixin Electronics Co., Ltd. delivers consistent quality through our certified processes and technical expertise.

Get a Custom Quote: Email sales@hrxfpc.com with your FPC/PCB specifications.

Learn More: Visit www.hrxfpc.com for ENIG case studies, FPC plating guides, and industry insights.

Elevate your electronics with reliable ENIG surface treatment—designed for performance, built for quality.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP