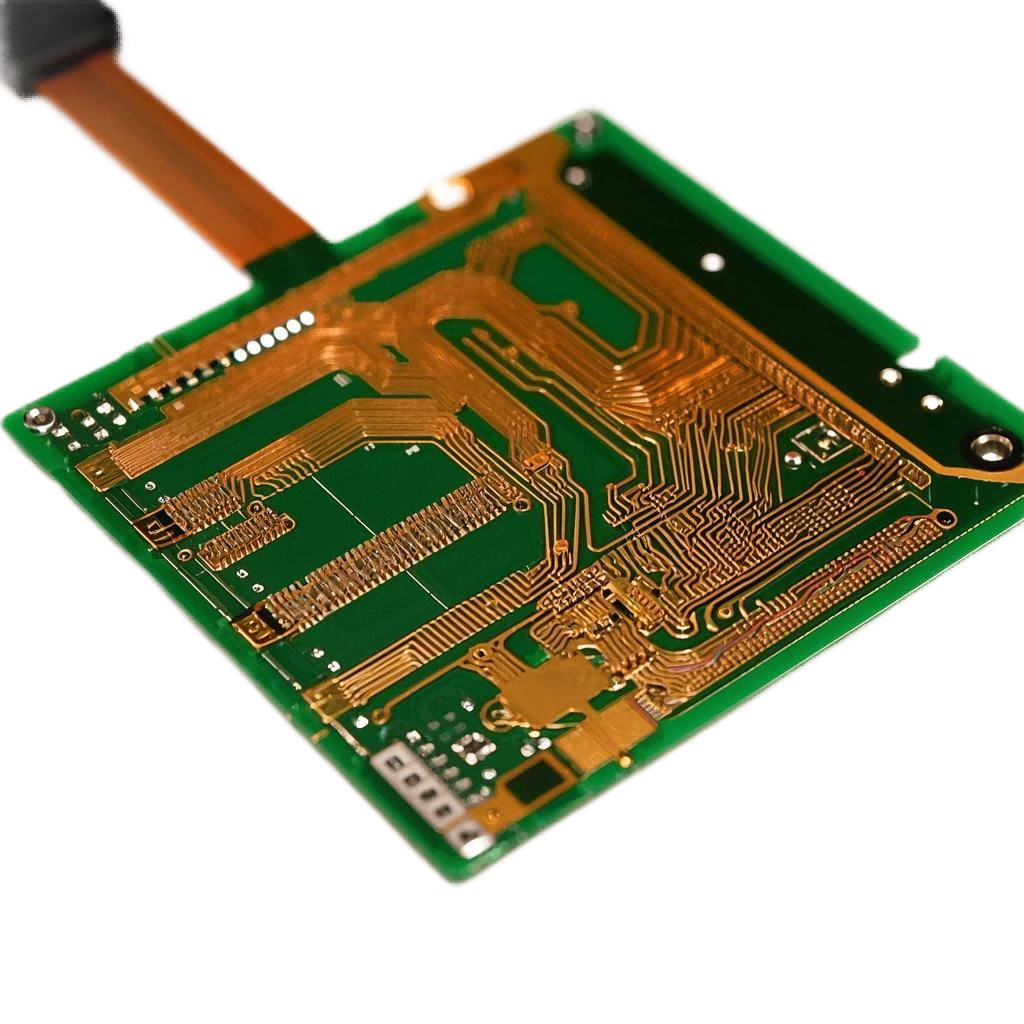

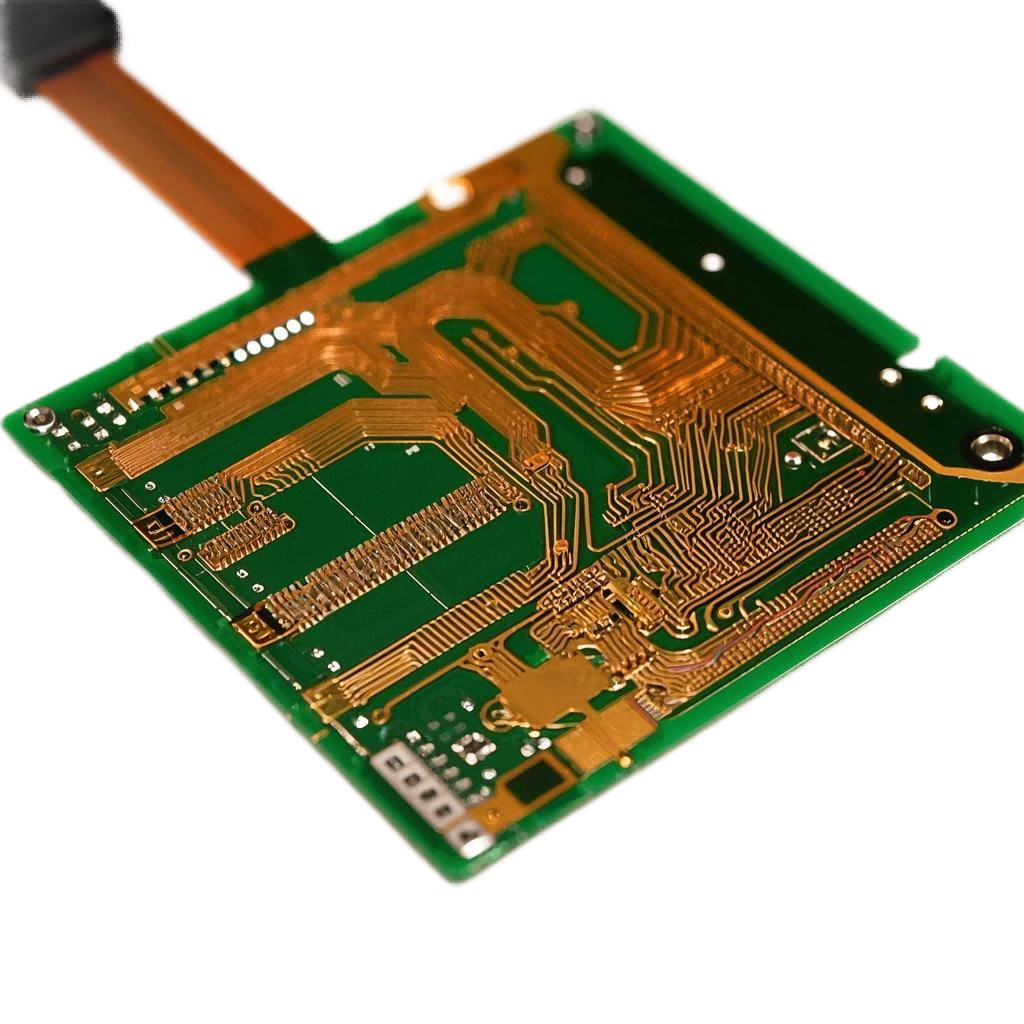

In the intricate landscape of designing and fabricating Flexible Printed Circuits (FPCs) for home appliances, the optimization of circuit design emerges as a linchpin. It wields a direct and profound influence over the performance, reliability, and functionality of these household apparatuses. Shenzhen Huaruixin Electronics Co., Ltd., armed with its profound and extensive expertise in FPC manufacturing and sales, is poised to offer invaluable insights and sagacious recommendations.

I. Signal Integrity

Problems:

Within the realm of home appliances such as high-definition televisions, audio systems, and smart home control panels, safeguarding signal integrity poses a formidable challenge. As FPCs serve as the conduits interconnecting diverse components, a litany of issues can surface, including crosstalk between signal traces, signal attenuation, and impedance mismatches. Crosstalk, that insidious interference between disparate signals, can precipitate distorted or erroneous data transmission. Signal attenuation, the enfeeblement of the signal en route to its destination component, can deleteriously affect its operational efficacy. Impedance mismatches, in turn, can spawn signal reflections, thereby further degrading the signal quality.

Avoidance and Suggestions:

1.Proper Trace Spacing and Routing: Sufficient inter-trace spacing must be meticulously maintained to curtail crosstalk. Signal traces ferrying high-speed signals ought to be routed at a judicious distance from other sensitive traces. For instance, in an FPC bridging the mainboard to the display panel of a television, the differential pairs for video signals should be segregated from power buses and other control signal lines. The deployment of ground planes and shielding layers interposed between distinct signal groups can also prove instrumental in minimizing crosstalk. Employing techniques such as guard traces and differential pair routing can enhance the isolation between signals.

2.Impedance Matching: It is imperative to ensure that the impedance of the signal traces is harmoniously matched to the stipulations of the connected components. This can be accomplished by astute selection of the trace width, thickness, and dielectric constant of the substrate. Impedance calculators and simulation software, such as advanced electromagnetic field simulators, can be enlisted during the design phase to ascertain the optimal trace parameters. The judicious addition of termination resistors at the termini of the signal lines serves to match the impedance and mitigate signal reflections.

3.Signal Filtering: The incorporation of appropriate filtering components, such as capacitors and ferrite beads, within the circuit is essential. Capacitors can be deployed to filter out high-frequency noise, while ferrite beads can quell common-mode and differential-mode noise. For example, in the power supply section of an appliance FPC, decoupling capacitors can be strategically placed to smoothen the DC voltage and attenuate voltage ripples. Ferrite beads can be adroitly added to the input and output lines of a switching regulator to impede the propagation of noise to other circuit segments.

II. Power Distribution

Problems:

Efficient power distribution is the cornerstone of the proper operation of home appliances. Inadequate power distribution can usher in voltage drops, overheating of components, and even catastrophic component failure. In appliances housing multiple power-consuming components, such as washing machines with motors and control circuits, or air conditioners with compressors and fans, ensuring a stable and ample power supply to each constituent is a Herculean task.

Avoidance and Suggestions:

1.Adequate Trace Width and Thickness: The width and thickness of the power traces on the FPC must be meticulously engineered in accordance with the current-carrying requisites of the components. Thicker and wider traces can adroitly handle higher currents sans significant voltage drops. For example, the power trace interfacing a high-power motor in a washing machine should be designed with a copious cross-sectional area to forestall overheating. The utilization of multiple parallel traces can also augment the current-carrying capacity. Implementing power trace width calculators based on copper foil thickness and current density can ensure accurate design.

2.Power Plane Design: The integration of power planes in the FPC design is a sagacious strategy. Power planes can proffer a low-impedance conduit for power distribution and contribute to the reduction of voltage drops. The power plane should be seamlessly connected to the power source and the components via vias. In a multi-layer FPC, segregating the power plane from the signal layers can minimize interference. Employing split power planes for different voltage domains can enhance power management flexibility.

3.Power Management and Protection: The incorporation of power management components, such as voltage regulators and fuses, within the FPC is non-negotiable. Voltage regulators can guarantee a stable output voltage to the components, compensating for any fluctuations in the input voltage. Fuses can safeguard the circuit from overcurrent exigencies. For example, a switching voltage regulator can be deployed to step down the input voltage to the requisite level for a specific component. A fuse, strategically placed in series with the power line to the motor, can thwart damage in the event of a short circuit.

III. Component Placement and Connectivity

Problems:

The disposition of components on the FPC and their interconnectivity can exert a profound impact on the holistic performance and manufacturability of the circuit. Incorrect component placement can engender elongated trace lengths, which can exacerbate signal loss and crosstalk. Flawed connectivity, such as unreliable soldering joints or loose connectors, can precipitate intermittent electrical connections and malfunction of the appliance.

Avoidance and Suggestions:

1.Optimal Component Placement: Components should be positioned in a manner that minimizes the length of the signal and power traces. Grouping related components in close proximity and situating them near the connectors or the mainboard they interface with is a prudent approach. For example, in a smart refrigerator's control FPC, the microcontroller and its affiliated sensors should be placed in propinquity to truncate the length of the sensor signal lines. This also augments the electromagnetic compatibility (EMC) of the circuit. Employing component placement algorithms and thermal analysis tools can optimize the layout.

2.Reliable Connectivity Design: The employment of high-quality connectors and the assurance of proper soldering techniques are sine qua non. The connectors should possess a secure mating mechanism and excellent electrical contact. The soldering process must be stringently controlled to ensure reliable joints. For example, in an FPC interfacing a display panel to a TV mainboard, the connectors should be capable of withstanding repeated insertions and withdrawals without compromising the electrical connection. Wave soldering or reflow soldering processes should be finessed to avert solder bridges, voids, or cold joints. Implementing automated optical inspection (AOI) and X-ray inspection for soldering quality control can enhance reliability.

3.Test Points and Debugging Features: The incorporation of test points in the FPC design streamlines testing and debugging. Test points can be harnessed to measure voltages, currents, and signals during the manufacturing process and in the event of field failures. Additionally, the addition of LEDs or other indicators can expedite the identification of the status of certain components or circuits. For example, a power-on LED can signify whether the power supply to the FPC is operational.

Shenzhen Huaruixin Electronics Co., Ltd. is resolutely committed to proffering premier FPC solutions for home appliances. By scrupulously considering these circuit design optimization factors and implementing the proffered measures, manufacturers can supercharge the performance and reliability of their home appliance products. We cordially welcome our customers to engage in discussions and consultations to further plumb the depths of the optimal circuit design practices for their specific home appliance applications.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.