Search

Bio-based Degradable Substrates in FPC/PCB/Rigid-Flex Boards: Features, Applications & Critical Considerations

- Nov 08,2025

-

Share

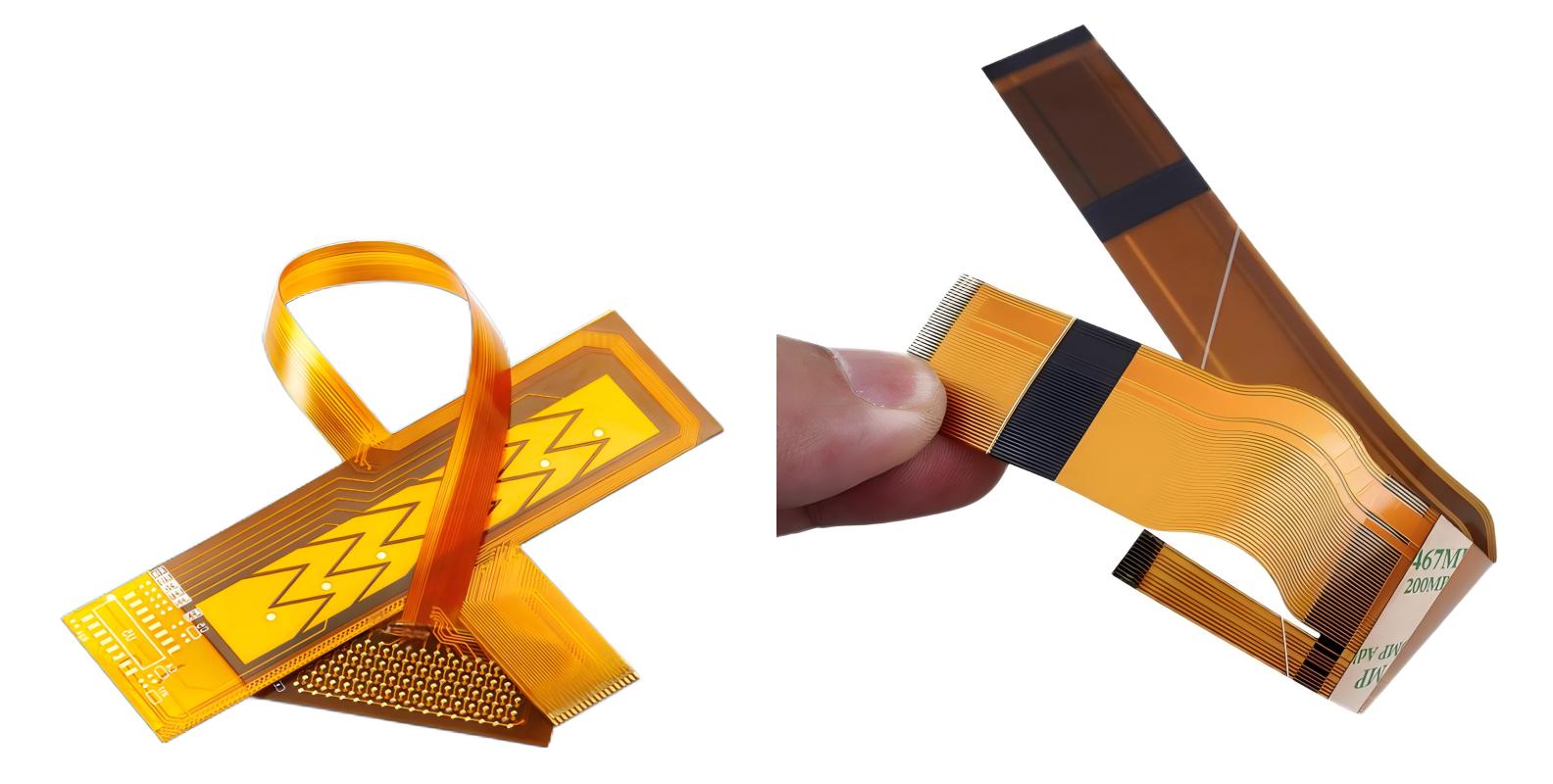

In the era of global environmental sustainability, bio-based degradable substrates have emerged as a transformative solution in the FPC (Flexible Printed Circuit), PCB (Printed Circuit Board), and rigid-flex board industries. These eco-friendly materials not only align with green manufacturing trends but also meet the evolving performance demands of high-tech applications. As a globally recognized ODM/OEM manufacturer in FPC, PCB, and rigid-flex board fields, Shenzhen Huaruixin Electronics Co., Ltd. holds GB/T19001-2016/ISO 9001:2015 quality management system certification, IAF international accreditation, and CNAS national recognition. With profound expertise in eco-friendly material integration, Huaruixin leads the industry in applying bio-based degradable substrates to deliver reliable, sustainable electronic solutions.

Core Features of Bio-based Degradable Substrates for FPC/PCB/Rigid-Flex Boards

Bio-based degradable substrates stand out for their unique combination of environmental friendliness and functional adaptability, making them ideal for advanced electronic manufacturing:

High Bio-based Content & Eco-friendliness: Derived from renewable resources like plant starches, cellulose, or polylactic acid (PLA), these substrates typically have a bio-based content of 60%–95%. Unlike traditional petroleum-based materials (e.g., FR-4), they decompose naturally under industrial composting conditions (20–30°C, 50% humidity) within 180–365 days, reducing electronic waste pollution.

Tailored Mechanical Performance: Optimized for flexible and rigid-flex applications, top-tier substrates (e.g., bio-based polyimide blends) offer tensile strength of 40–60 MPa and elongation at break of 15%–30%, matching the flexibility requirements of foldable device FPCs. Huaruixin’s custom formulations enhance tear resistance, ensuring durability in repeated bending scenarios.

Controlled Thermal & Chemical Stability: Advanced bio-based substrates maintain thermal stability up to 120–180°C, compatible with SMT (Surface Mount Technology) processes. They resist common electronic manufacturing chemicals (e.g., flux, cleaning agents) without degradation, ensuring process compatibility.

Low Carbon Footprint: The production process emits 30%–50% less CO₂ compared to petroleum-based substrates. Huaruixin’s lifecycle assessment (LCA) data shows that bio-based substrate FPCs reduce carbon emissions by 42% per unit compared to traditional alternatives.

Key Application Areas of Bio-based Degradable Substrates

The versatility of bio-based degradable substrates enables their adoption across high-growth electronic sectors, with Huaruixin driving implementation in:

Consumer Electronics: Used in flexible connectors, foldable phone hinges, and wearable device (smartwatch, fitness tracker) FPCs. For example, Huaruixin supplies bio-based FPCs to a leading smartwatch brand, where the substrate’s flexibility and degradability align with the product’s eco-friendly positioning.

Medical Devices: Ideal for disposable medical PCBs (e.g., diagnostic sensors, surgical instrument controllers) due to biocompatibility and degradability. Huaruixin’s ISO 9001-certified production ensures these substrates meet ISO 10993 biocompatibility standards, reducing environmental impact from medical waste.

Automotive Electronics: Applied in lightweight rigid-flex boards for electric vehicles (EVs), including battery management systems (BMS) and in-cabin sensors. The substrate’s low weight (15% lighter than FR-4) contributes to EV energy efficiency, while degradability supports end-of-life vehicle recycling.

IoT & Disposable Electronics: Used in low-power IoT sensors (e.g., environmental monitors, asset trackers) and disposable electronic devices. Huaruixin’s custom bio-based substrates enable cost-effective production of short-lifecycle IoT FPCs without compromising signal integrity.

Critical Considerations in Design, Production & Quality Inspection

Adopting bio-based degradable substrates requires precise process control to ensure performance and reliability. Huaruixin’s expertise highlights these key precautions:

Design Phase

Thickness & Flexibility Matching: Avoid excessive thickness (recommend 0.1–0.3 mm for FPCs) to maintain flexibility and degradability. For example, a wearable device FPC designed with 0.2 mm bio-based PLA substrate balances bendability and structural support.

Component Layout Optimization: Minimize stress concentration zones (e.g., near connectors) to prevent substrate tearing. Huaruixin’s design team uses finite element analysis (FEA) to simulate bending stress, ensuring compatibility with the substrate’s mechanical limits.

Compatibility with Adhesives & Inks: Select eco-friendly, low-temperature-curing adhesives and inks to avoid substrate degradation. Huaruixin tests adhesive-substrate compatibility for 500+ hours to ensure bonding stability.

Production Phase

Temperature Control: Limit processing temperatures to ≤180°C (depending on substrate type) to prevent thermal degradation. Huaruixin’s SMT lines feature precision temperature control (±2°C) for bio-based substrate assembly, avoiding material warpage.

Moisture Management: Bio-based substrates absorb moisture more easily than traditional materials. Pre-dry substrates at 80–100°C for 2–4 hours before production, as implemented in Huaruixin’s cleanroom facilities to prevent soldering defects.

Cutting & Forming: Use sharp, low-pressure tools to avoid substrate fraying. Huaruixin’s laser cutting technology ensures clean edges for bio-based rigid-flex boards, reducing material waste by 15%.

Quality Inspection Phase

Degradability Verification: Test substrates per ASTM D6400 (industrial composting) or ISO 14855 standards. Huaruixin’s in-house lab verifies ≥90% biodegradation within 1 year for all bio-based substrate products.

Mechanical Strength Testing: Conduct tensile, bending, and tear tests to ensure compliance with application requirements. For automotive BMS rigid-flex boards, Huaruixin requires ≥50 MPa tensile strength and 10,000+ bending cycles without failure.

Electrical Performance Validation: Measure dielectric constant (Dk: 2.8–3.5) and dielectric loss (Df: ≤0.01) to ensure signal integrity. Huaruixin uses vector network analyzers to test high-frequency bio-based FPCs (up to 10 GHz) for 5G applications.

Huaruixin’s Competitive Advantages in Bio-based Degradable Substrate Applications

As a certified and experienced manufacturer, Shenzhen Huaruixin Electronics Co., Ltd. offers unparalleled advantages in integrating bio-based degradable substrates:

Certified Quality Assurance: GB/T19001-2016/ISO 9001:2015, IAF, and CNAS certifications ensure strict adherence to global quality standards for bio-based substrate production.

Technical Expertise: 10+ years of experience in FPC/PCB/rigid-flex board design and manufacturing, with a dedicated R&D team specializing in bio-based material formulation and process optimization.

Customization Capabilities: Tailor bio-based substrates (thickness, flexibility, thermal resistance) to meet specific customer requirements, from consumer electronics to medical devices.

End-to-End Solutions: Provide ODM/OEM services covering design, prototyping, production, and testing, streamlining the adoption of bio-based substrates for clients worldwide.

Sustainable Manufacturing: Integrate bio-based materials into a low-carbon production chain, supporting clients’ environmental, social, and governance (ESG) goals.

If you have project requirements for FPC, PCB, or rigid-flex boards using bio-based degradable substrates, Huaruixin is your trusted professional manufacturer. For more industry insights, visit our website: www.hrxfpc.comor contact us via email: sales@hrxfpc.com to exchange knowledge, seek guidance, and collaborate on sustainable electronic solutions.

Whether you need custom bio-based substrate FPCs or technical support for eco-friendly manufacturing, Huaruixin’s expertise and certified processes ensure reliable, high-performance results aligned with global sustainability trends.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP