Search

Battery FPC Safety Standards and Professional Insights from Shenzhen Huaruixin Electronics Co., Ltd.

- Jun 17,2025

-

Share

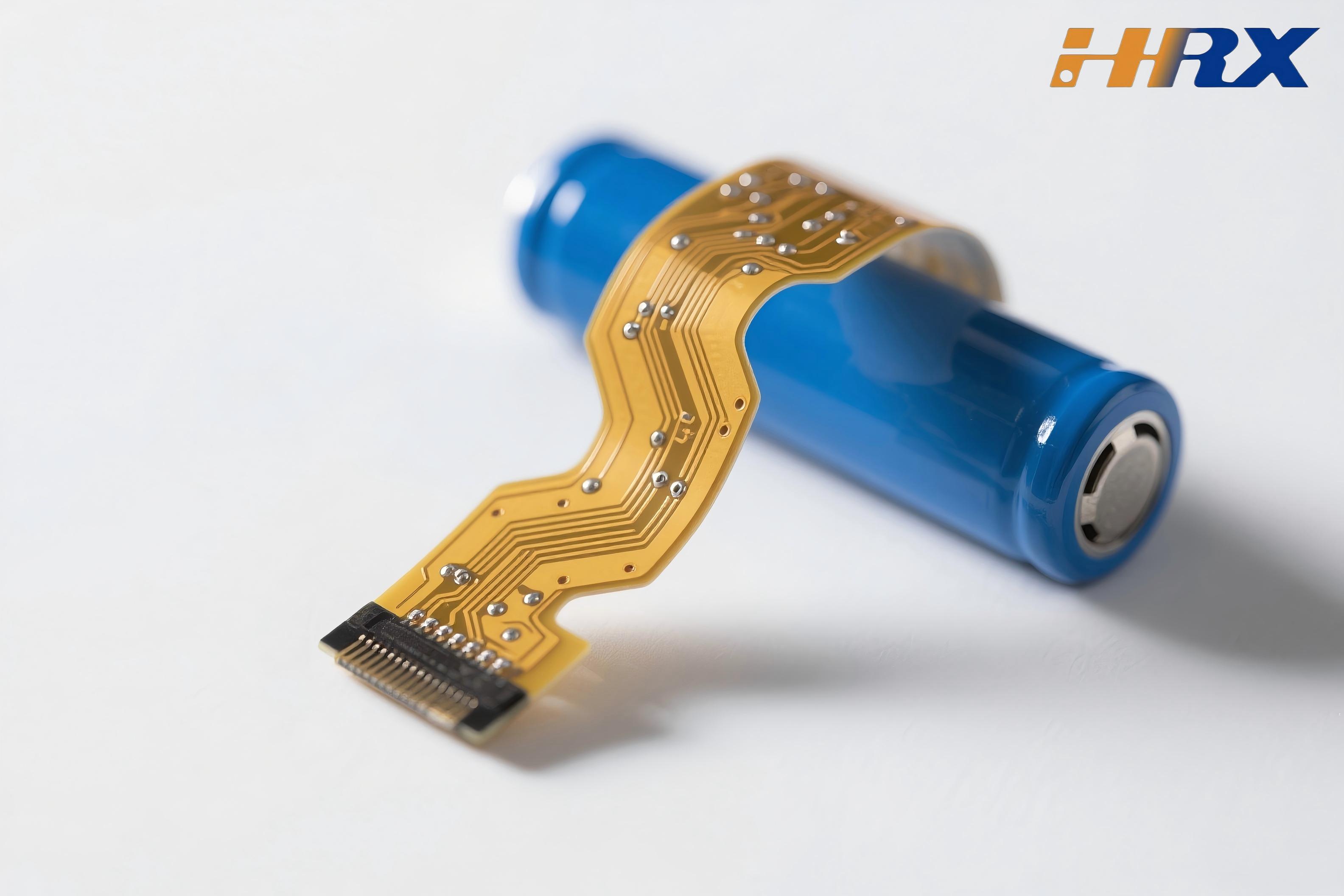

In the rapidly advancing realm of battery technology, Flexible Printed Circuits (FPCs) have emerged as pivotal components, leveraging flexible interconnect technology. Their unique attributes, including flexibility, space - efficiency, and high - density interconnection capabilities, render them the ideal choice for modern battery packs across diverse applications, ranging from consumer electronics to electric vehicles. However, given their critical role, adherence to stringent safety standards is non - negotiable. This blog aims to explore the key battery FPC safety standards and share the professional expertise of Shenzhen Huaruixin Electronics Co., Ltd., a globally recognized ODM/OEM manufacturer specializing in FPC, PCB, and Rigid - Flex Printed Boards, renowned for high - density FPC manufacturing.

1. International Safety Standards

1.1 IEC 62133

The International Electrotechnical Commission (IEC) 62133 standard is a cornerstone for rechargeable batteries and battery packs. When applied to FPCs in battery systems, it mandates requirements for electrical insulation, short - circuit protection, and overcharge prevention. For instance, FPCs must incorporate polyimide dielectric layers with superior electrical insulation properties to prevent leakage currents that could potentially lead to battery malfunction or fire hazards. Shenzhen Huaruixin Electronics strictly complies with IEC 62133 throughout the design and manufacturing lifecycle. Our R & D team employs advanced LCR meters to conduct meticulous insulation resistance tests, ensuring that every FPC adheres to the most stringent safety norms.

1.2 UL 2054 and UL 2056

Underwriters Laboratories (UL) 2054 focuses on the safety of household and commercial batteries, while UL 2056 pertains specifically to battery packs for portable devices. These standards encompass a broad spectrum of safety aspects relevant to FPCs, including mechanical durability, thermal stability, and flammability resistance. FPCs are required to endure mechanical stresses during battery assembly and operation without succumbing to fractures or causing electrical shorts. At Huaruixin, we utilize high - grade flexible substrates with excellent tensile strength and elongation properties. Our FPC designs are engineered to pass UL - specified mechanical impact and bend - cycle tests, ensuring long - term reliability and safety in battery applications.

2. Electrical Safety Requirements

2.1 Overcurrent Protection

Overcurrent conditions can induce excessive joule heating in FPCs, posing significant risks to battery integrity and safety. To mitigate these risks, FPCs should be integrated with advanced overcurrent protection mechanisms. This can be accomplished through the strategic placement of current - limiting resistors or the incorporation of specialized integrated circuit protection chips. Shenzhen Huaruixin Electronics boasts extensive experience in designing FPCs with optimized overcurrent protection circuits. Our engineers conduct in - depth current - carrying capacity analyses, considering factors such as trace width, copper thickness, and ambient temperature, to select the most suitable protection components for diverse battery applications.

2.2 Electrical Isolation

Robust electrical isolation between different electrical components on the FPC and between the FPC and the battery casing is essential. Insulation materials with high dielectric breakdown voltage, such as polyimide films with enhanced isolation properties, are employed, and the FPC layout is meticulously designed to minimize the risk of electrical arcing. We leverage state - of - the - art CAD software with advanced electrical rule checking (ERC) capabilities during the design process to ensure that electrical isolation distances meet or exceed safety standards. Additionally, our manufacturing process incorporates multi - stage quality control checks, including automated optical inspection (AOI) and X - ray inspection, to verify the integrity of the insulation layers.

3. Thermal Safety Considerations

3.1 Heat Dissipation

During battery operation, heat generation is inevitable, and efficient heat dissipation in FPCs is crucial to prevent thermal runaway. FPCs can be designed with advanced heat - dissipation features, such as thermal vias, large - area copper planes, and high - performance heat - conducting adhesives. At Huaruixin, we conduct comprehensive computational fluid dynamics (CFD) and finite element analysis (FEA) during the design phase to optimize the heat - dissipation structure of FPCs. Our experimental data demonstrates that well - designed heat - dissipation strategies can significantly reduce the operating temperature of FPCs in battery packs, thereby enhancing the overall safety and extending the lifespan of the battery system.

3.2 Thermal Stability of Materials

The materials used in FPCs must exhibit excellent thermal stability to withstand the cyclic temperature variations during battery charging and discharging processes. High - temperature - resistant polymers, such as liquid - crystal polymers (LCPs) and polybenzimidazole (PBI), along with high - performance adhesives with low thermal expansion coefficients, are preferred. We source materials from globally recognized suppliers and conduct rigorous in - house material testing, including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), to ensure that they meet the stringent thermal stability requirements. Our FPCs have been proven to maintain their mechanical and electrical performance even under extreme temperature conditions, ensuring reliable operation in demanding environments.

Professional Experiences and Suggestions from Shenzhen Huaruixin Electronics Co., Ltd.

With decades of experience in the design, development, and large - scale manufacturing of battery FPCs, we have amassed invaluable insights. One of our core principles is the importance of early - stage collaboration with customers. By thoroughly understanding the specific application scenarios, environmental conditions, and performance requirements of battery products at the project inception, we can develop FPC solutions that not only prioritize safety but also optimize functionality and cost - effectiveness.

We are also committed to continuous innovation in manufacturing processes. For example, we have adopted advanced laser direct imaging (LDI) and laser ablation techniques, which enable precise patterning of FPCs with fine - pitch traces and high aspect ratios. This precision manufacturing approach not only enhances the electrical performance and safety of our FPCs but also enables us to meet the evolving demands of the battery industry. Our advice to customers is to partner with a manufacturer that has a comprehensive quality management system, like Huaruixin, which holds certifications such as ISO 9001. These certifications are a testament to our commitment to manufacturing FPCs under strict quality control, ensuring compliance with both domestic and international safety standards.

If you have any project requirements related to FPCs, PCBs, or Rigid - Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. is your trusted professional partner. Our team of experienced engineers and technicians is dedicated to providing customized solutions tailored to your specific needs. Feel free to contact us at any time. For more in - depth industry knowledge and to explore our comprehensive product range, please visit our website at www.hrxfpc.comor send us an email at sales@hrxfpc.com. We look forward to the opportunity to collaborate, learn, and contribute to the success of your projects.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP