Search

Aperture Precision Assurance: Quality Management, Unique Advantages & Key Considerations at Shenzhen Huaruixin Electronics

- Sep 19,2025

-

Share

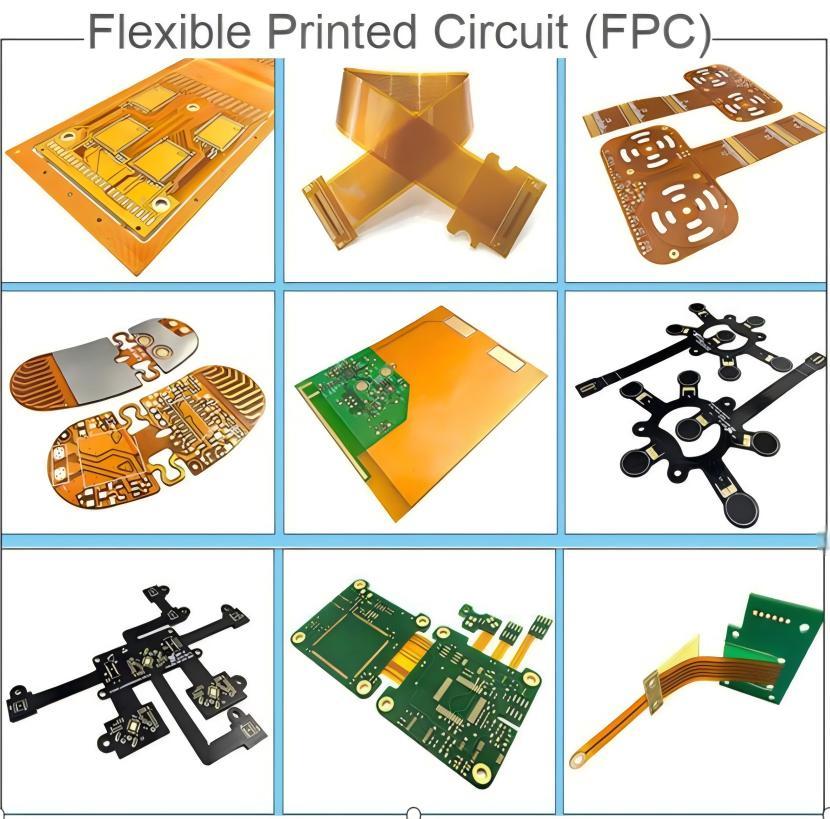

As a global professional ODM/OEM manufacturer specializing in FPC (Flexible Printed Circuit), PCB (Printed Circuit Board), and rigid-flex board production, Shenzhen Huaruixin Electronics Co., Ltd. stands out with robust capabilities. We boast a large-scale manufacturing base, deeply focus on product design and development, and have successfully obtained GB/T19001-2016/ISO 9001:2015 Quality Management System Certification, IAF International Accreditation, and CNAS National Accreditation. These credentials ensure the stability and reliability of our products and services at the system level, empowering global customers to maximize cooperation value.

Aperture precision is a critical indicator for FPC/PCB/rigid-flex boards, directly impacting component mounting, signal transmission, and overall product reliability. Below, we analyze our quality management measures for aperture precision, unique strengths, and key considerations—from the dual perspectives of design engineers and quality professionals—in a structured, priority-focused format.

1. Quality Management Measures for Aperture Precision

Our measures cover the full product lifecycle, from design to mass production, with a target of minimizing aperture deviation (critical holes: ±0.01mm tolerance).

1.1 Design Phase: Preventive Controls by Design Engineers

Design engineers lay the foundation for aperture precision through forward-looking, manufacturability-driven practices:

DFM (Design for Manufacturability) Validation: Utilize in-house DFM software integrated with real production data to audit hole specifications. For example, if a design calls for a 0.2mm hole for a 0402 passive component, the software automatically flags risks (e.g., drill bit wear causing oversize holes) and recommends optimizing to 0.22mm—based on historical process capability (Cpk ≥1.33) data.

Material & Process Matching: Select base materials (e.g., PI film for FPC, FR-4 for PCB) and drilling technologies (mechanical drilling for ≥0.15mm holes, laser drilling for <0.15mm micro-holes) aligned with aperture requirements. For rigid-flex boards, design engineers collaborate with process teams to avoid hole placement in flexible folding zones—preventing drill bit deflection during production.

Tolerance Standardization: Adhere to IPC-6012/2221 standards to define feasible aperture tolerances. For high-reliability sectors (e.g., automotive, medical electronics), tighter tolerances (±0.005mm) are specified, with cross-reviews by quality engineers to ensure measurability via advanced inspection tools.

1.2 Production Phase: Process Controls by Quality Professionals

Quality professionals enforce real-time monitoring and validation to maintain aperture precision:

Pre-Production Calibration: Calibrate drilling equipment (mechanical/laser) using standard test panels before each run. For mechanical drills, verify drill bit runout (≤0.003mm) and sharpness; for laser drills, confirm laser power and focus alignment (calibrated to material thickness).

In-Process Inspection (IPI): Conduct sampling inspections at 3 critical stages using automated tools:

Post-drilling: Use Coordinate Measuring Machines (CMM) to check hole diameter and position accuracy;

Post-plating: Employ Automated Optical Inspection (AOI) to verify that copper plating does not reduce hole diameter beyond tolerance (plating thickness deviation ≤0.002mm);

Post-lamination (rigid-flex boards): Inspect for hole deformation caused by lamination pressure using 3D laser scanners.

Statistical Process Control (SPC): Collect aperture data (50 samples per production lot) and use SPC charts to monitor stability. If Cpk drops below 1.33 (ISO 9001 requirement), production is paused to identify root causes (e.g., material variation, drill machine vibration) and implement corrective actions.

2. Unique Advantages in Aperture Precision Management

What differentiates Huaruixin lies in our "design-quality integration" and tailored solutions for complex board types:

2.1 Design-Quality Collaboration Platform

We’ve built a digital shared platform that connects design and quality teams in real time:

Design engineers access historical aperture deviation data (e.g., "laser drilling for 0.1mm PI holes has a Cpk of 1.67") to optimize new designs;

Quality professionals track design changes (e.g., new hole sizes for 5G components) and update inspection plans instantly—eliminating misalignment between design intent and production reality.

2.2 Rigid-Flex Board-Specific Solutions

Rigid-flex boards pose unique aperture challenges (e.g., uneven material stiffness). Our proprietary approaches include:

Dual-Drilling Strategy: Use mechanical drilling for rigid regions (thicker material, larger holes) and laser drilling for flexible regions (thinner PI, micro-holes);

Flex Zone Fixturing: Quality teams use custom vacuum fixtures to secure flexible regions during drilling—reducing hole position deviation by 40% compared to standard fixtures.

2.3 End-to-End Traceability

Every hole in our products is traceable to the production batch, drilling machine, operator, and inspection records (aligned with ISO 9001/IAF/CNAS requirements). If a customer reports an aperture issue, we can retrieve full data within 1 hour to resolve root causes—ensuring accountability and rapid response.

3. Key Considerations for Design & Quality Teams

Sustaining aperture precision requires proactive attention to these critical factors:

3.1 For Design Engineers

Avoid Over-Specification: Do not set tighter tolerances than necessary (e.g., ±0.005mm for non-critical holes). Collaborate with quality teams to balance design requirements with manufacturing feasibility—reducing costs and improving yield.

Account for Post-Processing Shrinkage: FPC materials (e.g., PI) may shrink during lamination. Design engineers must adjust hole positions by 0.002–0.003mm to compensate—based on material shrinkage test data.

Update DFM Libraries: Regularly integrate new materials (e.g., high-temperature PI for automotive FPC) and processes (e.g., UV laser drilling for HDI PCBs) into DFM tools—ensuring designs reflect the latest manufacturing capabilities.

3.2 For Quality Professionals

Drill Bit Lifespan Management: Mechanical drill bits wear after ~500 holes (varies by material). Establish a replacement schedule and inspect bits for chipping—chipped bits cause irregular hole shapes.

Environmental Control: Maintain production workshop temperature (23±2℃) and humidity (50±5%). High humidity causes FR-4/PI to absorb moisture, leading to drill bit slipping—install real-time environmental monitors with alerts.

New Process Validation: Before launching a new process (e.g., laser drilling for 0.08mm micro-holes), conduct a 10-batch stability test and verify Cpk ≥1.33—ensuring consistency before mass production.

Partner with Huaruixin for Precision FPC/PCB Solutions

If you have projects requiring high-precision FPC, PCB, or rigid-flex boards, Shenzhen Huaruixin Electronics Co., Ltd. is your trusted ODM/OEM partner—backed by ISO 9001/IAF/CNAS certifications and proven aperture precision management.

Learn more about our technologies and capabilities: Visit www.hrxfpc.com;

For personalized consultation or project discussions: Email sales@hrxfpc.com.

We welcome the opportunity to exchange industry knowledge, support your project success, and grow together!

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP