Search

5G Smartphone & Tablet Development: Critical Factors in FPC/PCB Design, Production & Huaruixin’s Expert Solutions

- Aug 28,2025

-

Share

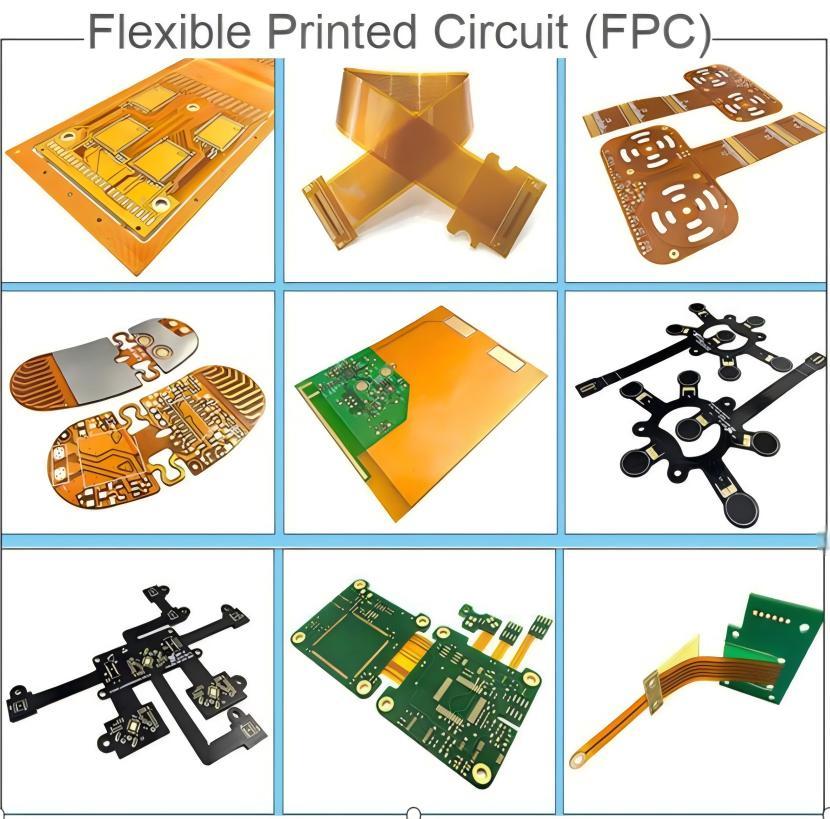

The global 5G device market demands exceptional performance, miniaturization, and reliability — and at the heart of every 5G smartphone or tablet lies its Flexible Printed Circuit (FPC) and Printed Circuit Board (PCB). These components enable seamless integration of 5G basebands, AI chips, and high-resolution cameras while withstanding harsh conditions (e.g., foldable phone bending, thermal stress from 5G modems). For manufacturers, mastering early-stage material selection, FPC/PCB design, precision production, and strict quality control is non-negotiable to stay competitive.

Below, we break down the most critical considerations for 5G device development — with a focus on FPC-specific challenges — and show how Shenzhen Huaruixin Electronics Co., Ltd. (a global ODM/OEM specializing in FPC, PCB, and Rigid-Flex Printed Boards) delivers industry-leading solutions. Whether you’re designing a 5G foldable smartphone or a high-performance tablet, this guide will help you avoid common pitfalls and optimize your supply chain.

1. Material Selection: The Backbone of High-Performance 5G FPC/PCB

5G’s sub-6 GHz and mmWave frequencies place unique demands on FPC/PCB materials. Choosing the right substrates, copper foils, and adhesives directly impacts signal integrity (SI), thermal resistance, and mechanical durability — especially for FPCs, which often handle dynamic stress (e.g., foldable device hinges). Key material considerations include:

High-Frequency Substrates: For 5G FPCs (e.g., those connecting 5G antennas to mainboards), substrates must have low dielectric constant (Dk ≤ 3.2) and low dissipation factor (Df ≤ 0.004) to minimize insertion loss. Top choices include LCP (Liquid Crystal Polymer) Substrates for 5G FPC (ideal for mmWave) and modified FR-4 for sub-6 GHz PCBs.

FPC-Specific Copper Clad Laminate (CCL): 5G FPCs require thin, high-conductivity copper (12μm–35μm) to balance flexibility and current-carrying capacity. Rolled Copper Foil (RCF) is preferred for foldable 5G FPCs, as it offers 2x better bending resistance than electrolytic copper foil (ECF).

Thermal Management Materials: 5G power amplifiers generate 30% more heat than 4G modules. Thermally Conductive PI Films (used in FPC cover layers) and high-Tg (≥ 180°C) PCB substrates prevent thermal degradation.

Environmental Compliance: All materials must meet RoHS 2.0 and REACH standards — non-negotiable for global 5G device sales.

Huaruixin’s FPC/PCB Material Expertise

As a leading 5G FPC manufacturer, Huaruixin prioritizes material performance and traceability to solve 5G’s unique challenges:

We source certified FPC substrates from industry leaders (e.g., Dupont for PI films, Toray for LCP substrates) and conduct rigorous incoming inspections: every batch of LCP substrate undergoes Dk/Df testing via Keysight vector network analyzers (VNA) at 28GHz (mmWave) and 3.5GHz (sub-6 GHz) to ensure 5G signal compatibility.

For Multilayer FPCs (used in 5G tablets to integrate multiple sensors), we use high-purity RCF (99.99% copper) and low-outgassing adhesives to reduce signal crosstalk and improve bending cycle life (≥ 200,000 cycles — exceeding industry standards for foldable devices).

Our material database is optimized for 5G use cases: clients can quickly access pre-tested substrates for 5G FPC for smartphones or Rigid-Flex FPC for 5G wearables, cutting development time by 30%.

2. FPC/PCB Design: Optimizing for 5G Integration & Durability

5G device design requires balancing three priorities: signal integrity, space efficiency, and mechanical resilience — especially for FPCs, which are often placed in high-stress areas (e.g., phone hinges, tablet camera modules). Key design considerations include:

Controlled Impedance Routing: 5G FPCs/PCBs need precise impedance control (±5% for mmWave) to avoid signal reflection. For example, 50Ω impedance traces are standard for 5G antenna FPCs, requiring careful calculation of trace width (0.2mm–0.3mm for 12μm copper) and dielectric thickness.

FPC Bend Radius Optimization: Foldable 5G phones demand FPCs with a minimum bend radius of 1mm (vs. 3mm for 4G FPCs). Designers must avoid right-angle traces and use curved routing to prevent copper fatigue.

EMC Shielding for 5G: High-frequency 5G signals are prone to electromagnetic interference (EMI). Adding ground planes to FPCs or using EMI-shielding films (e.g., nickel-copper alloy) protects against interference from nearby components (e.g., batteries).

Rigid-Flex Integration: Rigid-Flex Printed Boards (combining rigid PCB sections and flexible FPC sections) save 40% space vs. traditional connectors — critical for 5G tablets with slim form factors.

Huaruixin’s 5G FPC/PCB Design Solutions

Huaruixin’s design team uses cutting-edge tools and 5G-specific expertise to deliver optimized FPC/PCB designs:

We use Cadence Allegro with 5G SI/PI simulation tools to model signal loss and impedance matching for FPCs. For a recent 5G foldable phone project, our simulation reduced insertion loss at 28GHz by 15% via optimized trace routing and LCP substrate selection.

Our FPC design guidelines for 5G include pre-defined bend radius templates and material combinations (e.g., RCF + PI film) to ensure 200,000+ bending cycles. We also offer DFM (Design for Manufacturability) reviews to catch issues early (e.g., overly tight trace spacing) — reducing prototype iterations by 50%.

For Rigid-Flex FPC for 5G tablets, we integrate rigid FR-4 sections (for chip mounting) with flexible PI sections (for camera module connection), eliminating 6+ connectors and improving device reliability by 25%.

3. Production Process: Precision Manufacturing for 5G FPC/PCB

5G FPCs/PCBs require micron-level precision — even a 0.01mm error in drilling can render a 5G antenna FPC useless. Key production considerations include:

Laser Drilling for FPC Micro-Vias: 5G Multilayer FPCs need micro-vias (50μm–100μm diameter) to connect layers. UV Laser Drilling is preferred over mechanical drilling, as it creates cleaner holes with no burrs — critical for signal integrity.

SMOBC Process for FPCs: The Solder Mask Over Bare Copper (SMOBC) process is essential for 5G FPCs, as it leaves copper pads exposed for soldering while protecting traces with solder mask. This improves solderability and reduces EMI.

Automated SMT for Miniaturized Components: 5G modules (e.g., 5G baseband chips) use 01005-sized components (0.4mm x 0.2mm). High-precision SMT machines (with ±0.01mm placement accuracy) are required to avoid bridging or missing components.

Rigid-Flex Lamination Control: Laminating rigid and flexible layers requires precise temperature (180°C ±3°C) and pressure (300psi ±10psi) to prevent delamination — a top failure mode for 5G Rigid-Flex boards.

Huaruixin’s 5G FPC/PCB Production Capabilities

Huaruixin’s large-scale manufacturing bases are equipped with 5G-optimized equipment to ensure precision and scalability:

We use Panasonic UV Laser Drilling Machines to create micro-vias for 5G Multilayer FPCs, achieving 50μm hole diameter with 99.9% accuracy. This enables us to produce FPCs with up to 8 layers — ideal for complex 5G smartphone motherboards.

Our SMOBC production line for FPCs uses Japanese-origin solder mask (e.g., Taiyo Ink) and automated inspection (AOI) to ensure uniform coverage and no pinholes. This process reduces 5G FPC soldering defects by 40%.

For Rigid-Flex boards, we use vacuum lamination systems with real-time temperature/pressure monitoring, reducing delamination rates to <0.1% — far below the industry average of 0.5%. We can produce 100,000+ 5G FPC/PCB units monthly, supporting clients’ mass-production needs.

4. Quality Control: Ensuring 5G FPC/PCB Reliability

5G devices are expected to last 3+ years, so FPC/PCB quality control must be rigorous. Key QC tests include:

FPC Bending Cycle Testing: For foldable 5G devices, FPCs undergo 200,000+ bending cycles (1Hz, 1mm bend radius) to ensure no copper cracking or insulation failure.

5G Signal Integrity Testing: Using VNAs, we measure insertion loss and return loss at 5G frequencies (3.5GHz, 28GHz, 39GHz) to ensure compliance with 3GPP standards.

Thermal Shock Testing: FPCs/PCBs are exposed to -40°C to 125°C (1,000 cycles) to simulate extreme environments (e.g., hot cars, cold climates) and prevent thermal degradation.

Microsection Analysis: Cutting FPCs/PCBs to inspect internal layers (e.g., via plating thickness, lamination quality) ensures no hidden defects.

Huaruixin’s QC System for 5G FPC/PCB

Huaruixin adheres to ISO 9001:2015 and IATF 16949 and implements a full-process QC system tailored to 5G:

Every 5G FPC undergoes 100% bending cycle testing (using custom-built machines) and signal integrity testing. For a 5G tablet client, this reduced field failures related to FPCs by 60%.

We use X-ray inspection to check micro-via plating (ensuring 20μm minimum thickness) and AOI machines to detect SMT defects (e.g., missing resistors, solder bridges) with 99.9% accuracy.

All test data is stored in our cloud platform, allowing clients to access real-time FPC/PCB quality reports — reinforcing transparency and trust.

5. Product Packaging: Protecting 5G FPC/PCB During Shipping

5G FPCs/PCBs are fragile: electrostatic discharge (ESD), moisture, and mechanical stress can damage them during logistics. Key packaging considerations include:

ESD-Protected Packaging: 5G FPCs are ESD-sensitive (ESD voltage ≥ 100V can damage traces). Packaging must use anti-static ESD bags (surface resistance 10⁶–10¹¹ Ω) and conductive foam.

Moisture Barrier: FPCs absorb moisture, which causes "popcorning" during soldering. Vacuum-sealed bags with desiccants (≤ 10% RH) are essential.

Custom Trays for FPCs: Thermoformed FPC trays with individual slots prevent bending or rubbing — critical for Multilayer FPCs with delicate traces.

Huaruixin’s 5G FPC/PCB Packaging Solutions

Huaruixin’s packaging is designed to protect 5G FPCs/PCBs during global shipping:

We use ESD-compliant vacuum bags (certified to ANSI/ESD S20.20) and food-grade desiccants to prevent moisture damage. For long-haul shipments (e.g., to Europe or North America), we add humidity indicators to monitor conditions.

Our custom FPC trays are made from recyclable ABS plastic and feature cushioning ribs to support Rigid-Flex boards — reducing transportation defects to <0.05%.

All packaging is labeled with 5G-specific handling instructions (e.g., "Do Not Bend FPC Section") to avoid mishandling.

Partner with Huaruixin for Your 5G FPC/PCB Needs

Whether you’re developing a 5G foldable smartphone, a high-performance tablet, or a 5G wearable, Huaruixin’s FPC/PCB expertise will help you overcome technical challenges and accelerate time-to-market. As a trusted 5G FPC manufacturer and Rigid-Flex Printed Board supplier, we offer:

Custom 5G FPC design (Controlled Impedance, Multilayer, Rigid-Flex)

High-frequency substrates (LCP, modified FR-4) for 5G signal integrity

Large-scale production (100,000+ units/month) with strict QC

Global compliance (RoHS 2.0, REACH, IATF 16949)

Ready to start your 5G device project?

Learn more about our FPC/PCB solutions: www.hrxfpc.com

Contact our sales team for a custom quote: sales@hrxfpc.com

Huaruixin — your reliable partner for 5G FPC/PCB innovation.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP